SecuringtheCuttingUnits

1.EnsurethatthePTOisdisengaged.

2.Parkthemachineonalevelsurface.

3.Engagetheparkingbrake.

4.Fullyraisethecuttingunits.

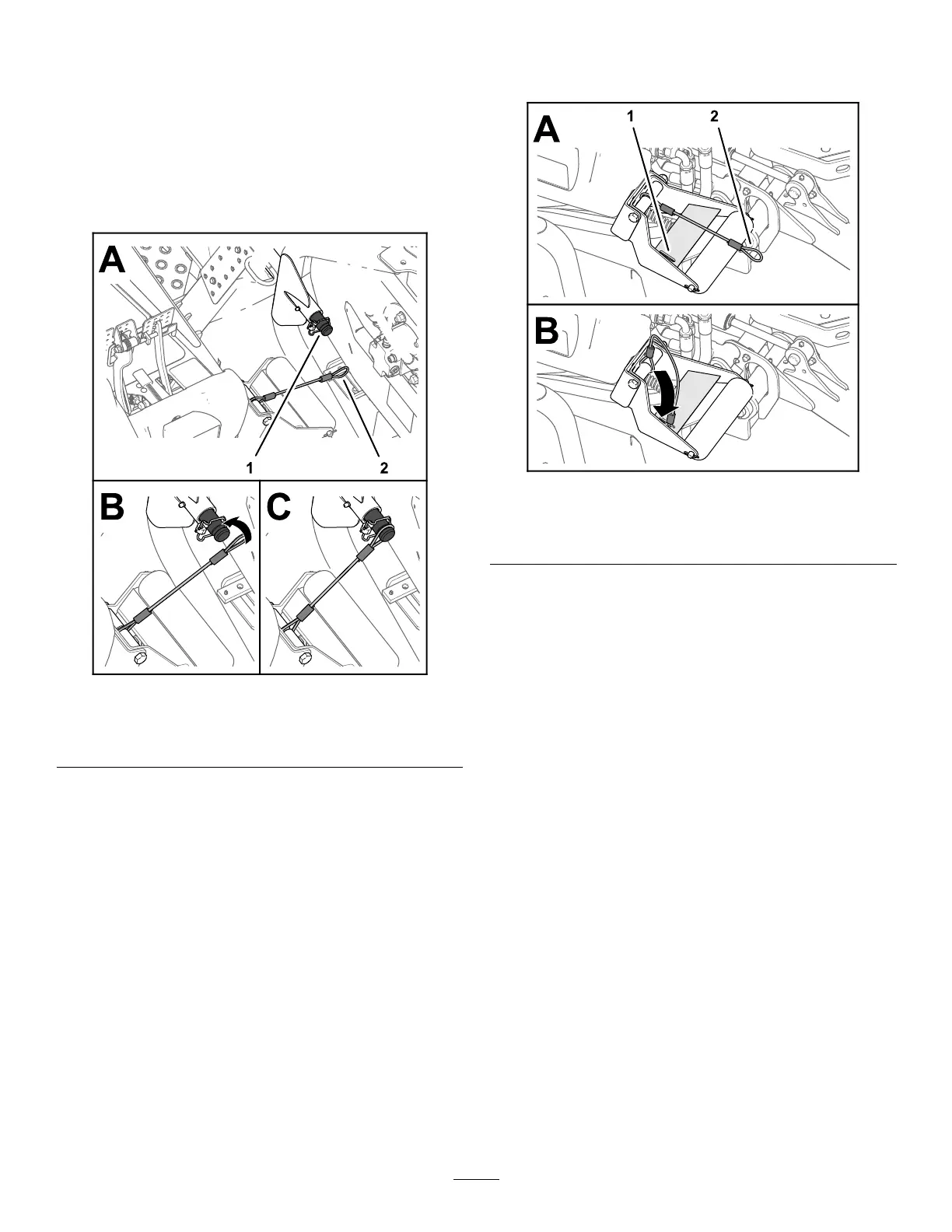

5.Alignthelanyardtothecarriershaftofthelift

armfortheforwardouter-cuttingunit(Figure26).

g225483

Figure26

1.Carrier-shaftgroove

(forwardouter-liftarm)

2.Lanyardloop

6.Sliptheloopinthelanyardoverthecarriershaft

untilthelanyardisfullyseatedinthegroovein

theshaft(Figure26).

7.Repeatsteps5and6fortheforward

outer-cuttingunitattheothersideofthe

machine.

Important:Removethelanyardsfromthecarrier

shaftsbeforeloweringthecuttingunits

StowingtheLanyards

Note:Stowthelanyardswhenyouarenotusing

them.

1.EnsurethatthePTOisdisengaged.

2.Parkthemachineonalevelsurface.

3.Engagetheparkingbrake.

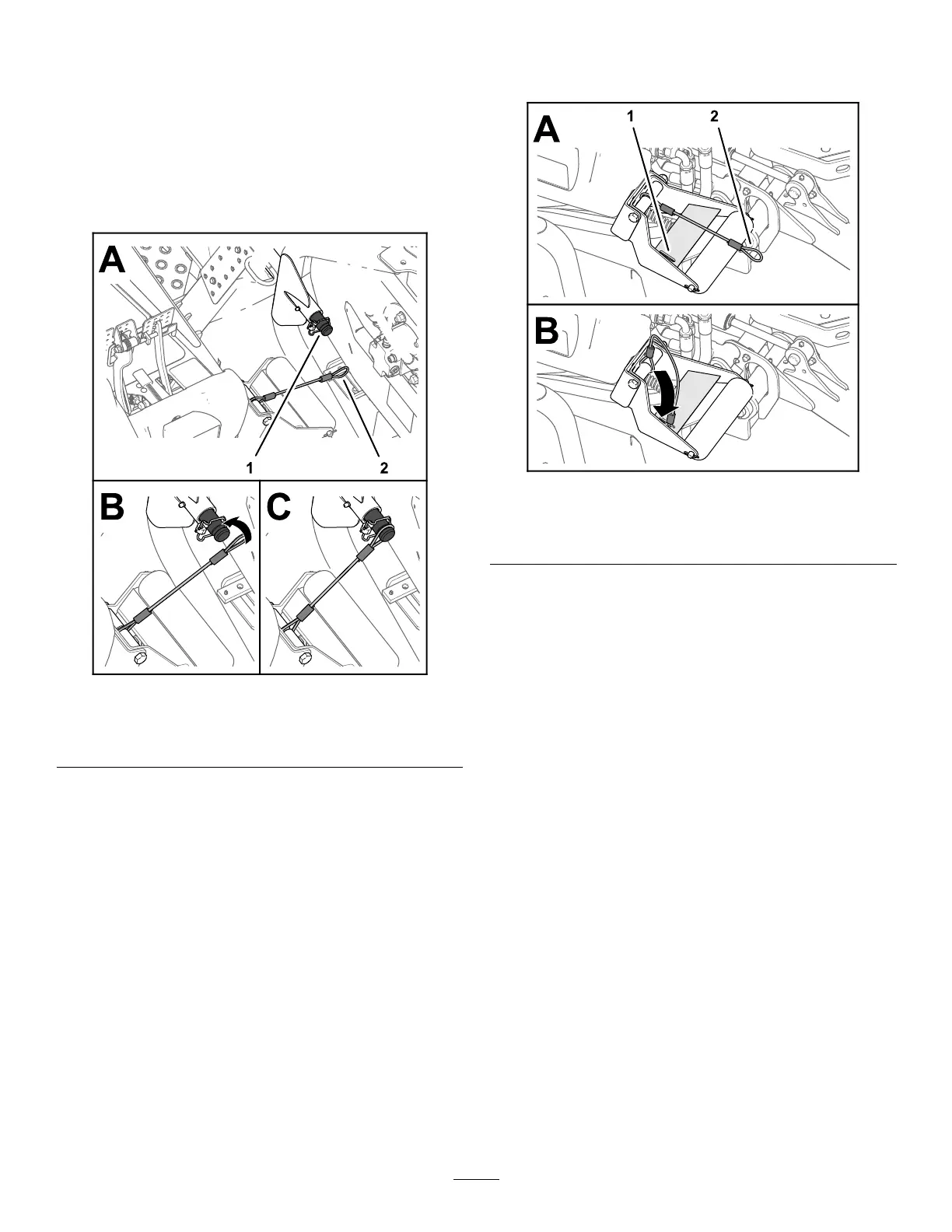

4.Withthecuttingunitslowered,sliptheloopof

thelanyardintotheslotinthereinforcement

plateoftherollersupport(Figure27).

g225485

Figure27

1.Reinforcement-plateslot

(rollersupport)

2.Lanyardloop

HaulingtheMachine

•Removethekeyandshutoffthefuel(ifequipped)

beforestoringorhaulingthemachine.

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Usefull-widthrampsforloadingthemachineinto

atraileroratruck.

•Tiethemachinedownsecurely.

PushingorTowingthe

Machine

Inanemergency,youcanmovethemachine

forwardbyactuatingthebypassvalveinthe

variable-displacementhydraulicpumpandpushingor

towingthemachine.

Important:Donotpushortowthemachinefaster

than3to4.8km/h(2to3mph).Ifyoupushortow

atafasterspeed,internaltransmissiondamage

mayoccur.

Thebypassvalvesmustbeopenwheneveryou

pushortowthemachine.

1.Openthehoodandlocatethebypassvalves

(Figure28)onthetopofpump,behindthe

battery/storageboxes.

36

Loading...

Loading...