InstallingtheCuttingUnits

1.Movethecuttingunitintopositioninfrontofthe

machine.

2.Slidethecuttingunit-carrierframeontothe

lift-arm-pivotpin(Figure79).Securethe

cuttingunittothepinwiththelynchpin(for

Groundsmaster4500machines)orretainingnut

(forGroundsmaster4700machines).

3.Installthehydraulicmotortothecuttingunit

(Figure78).MakesurethattheO-ringisin

positionandnotdamaged.

4.Greasethespindle.

ServicingtheFrontRoller

Inspectthefrontrollerforwear,excesswobble,or

binding.Serviceorreplacetherollerorcomponentsif

anyoftheseconditionsexist.

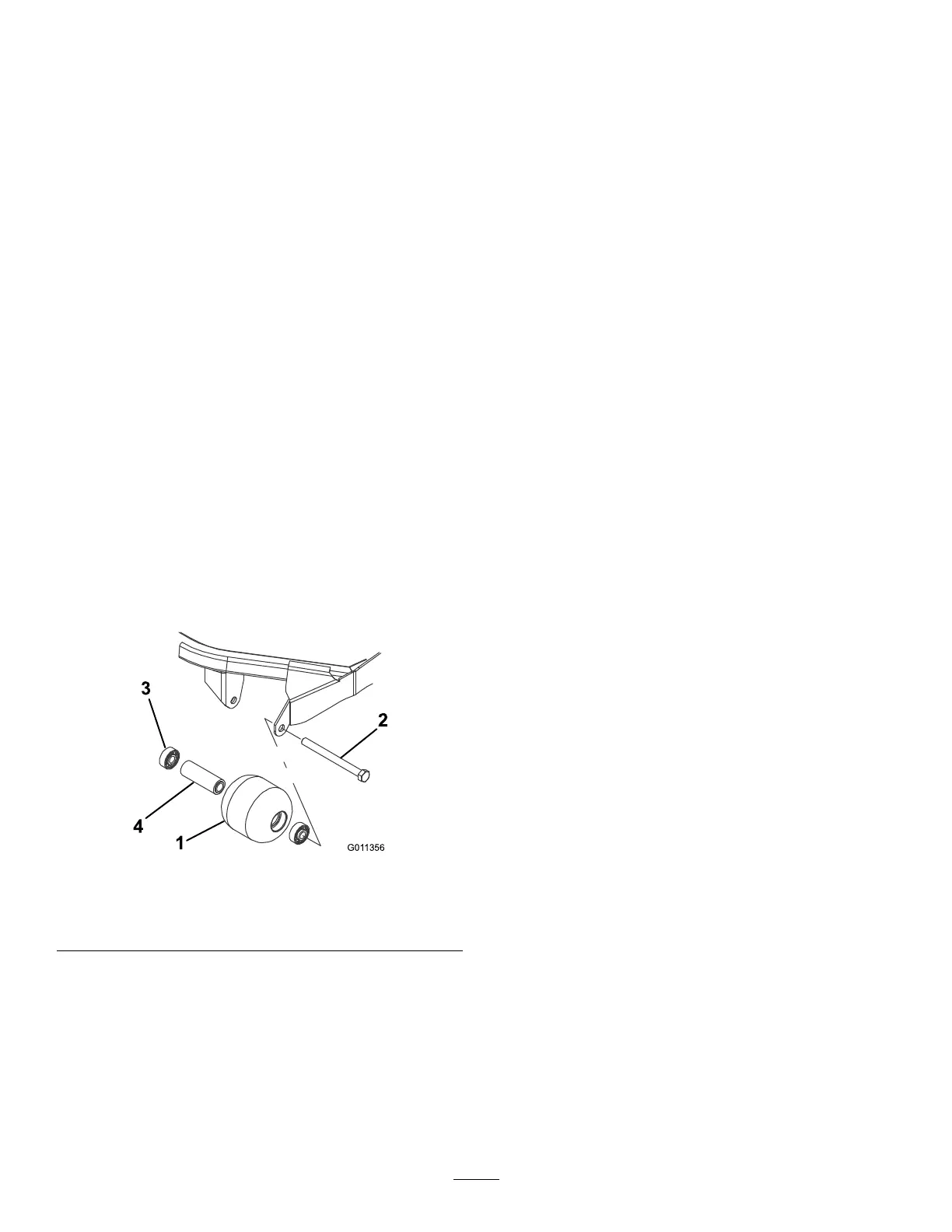

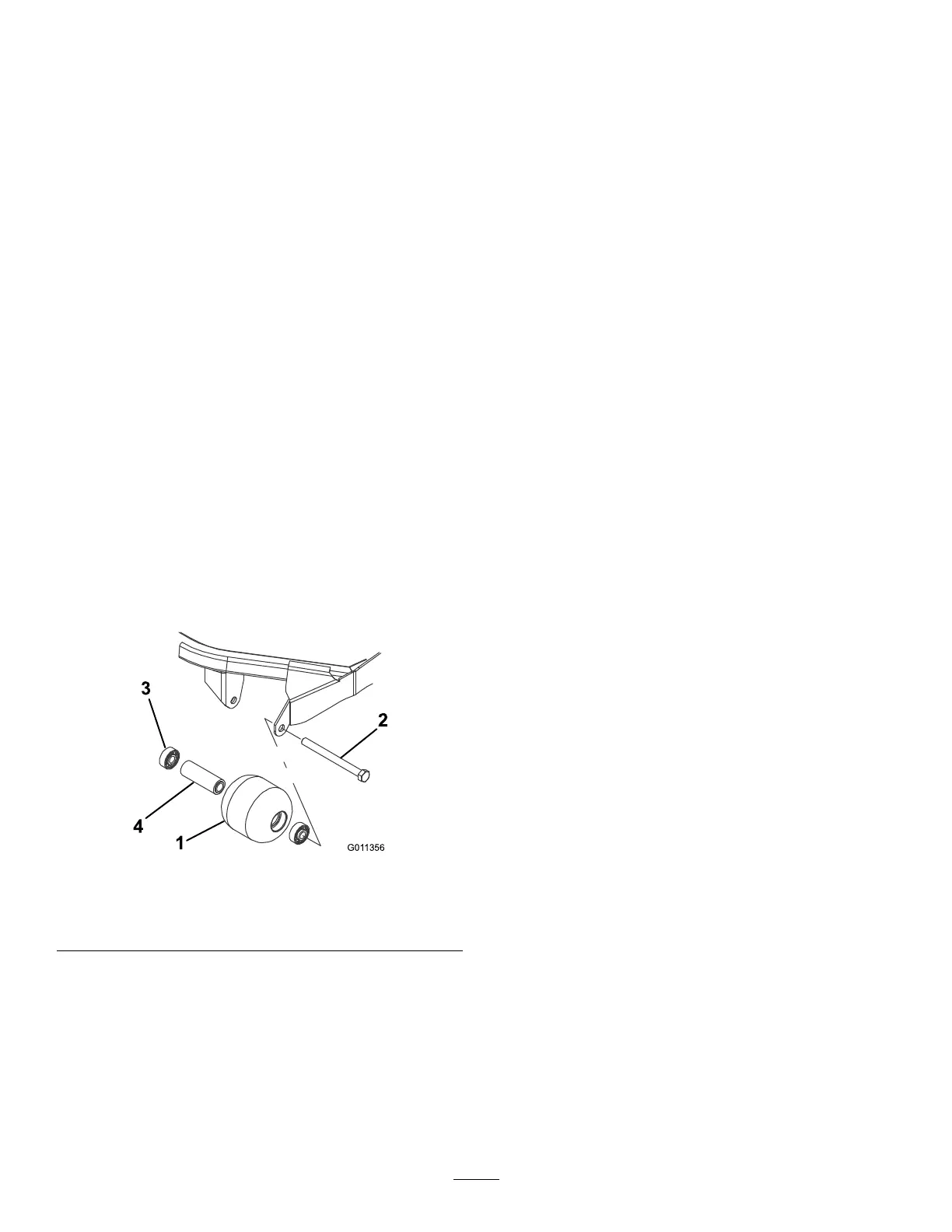

DisassemblingtheFrontRoller

1.Removetheroller-mountingbolt(Figure80).

2.Insertapunchthroughtheendoftheroller

housinganddrivetheoppositebearingoutby

alternatingtapstotheoppositesideofinner

bearingrace.Thereshouldbea1.5mm(0.060

inch)lipofinnerraceexposed.

g011356

Figure80

1.Frontroller3.Bearing

2.Mountingbolt4.Bearingspacer

3.Pushthesecondbearingoutinpress.

4.Inspecttherollerhousing,bearings,andbearing

spacerfordamage(Figure80).Replaceany

damagedcomponentsandassemblethem.

AssemblingtheFrontRoller

1.Presstherstbearingintotherollerhousing

(Figure80).Pressontheouterraceonlyor

equallyontheinnerandouterrace.

2.Insertthespacer(Figure80).

3.Pressthesecondbearingintotherollerhousing

(Figure80).Pressingequallyontheinnerand

outerraceuntiltheinnerracecontactsthe

spacer.

4.Installtherollerassemblyintothecutting-unit

frame.

5.Verifythatthereisnomorethana1.5mm(0.060

inch)gapbetweenrollerassemblyandtheroller

mountbracketsofthecutting-unitframe.Ifthere

isagapover1.5mm(0.060inch),installenough

5/8-inchdiameterwasherstotakeuptheslop.

Important:Securingtherollerassembly

withagaplargerthan1.5mm(0.060inch)

createsasideloadonthebearingandcan

leadtoprematurebearingfailure

6.Torquethemountingboltto108N∙m(80ft-lb).

64

Loading...

Loading...