CheckingtheHydraulic

LinesandHoses

ServiceInterval:Beforeeachuseordaily

Every2years

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operatingthemachine.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Seekimmediatemedicalhelpifuidis

injectedintoskin.

•Makesurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

CuttingUnitMaintenance

RemovingtheCuttingUnits

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,lowerthecuttingunits,shutoff

theengine,andremovethekey.

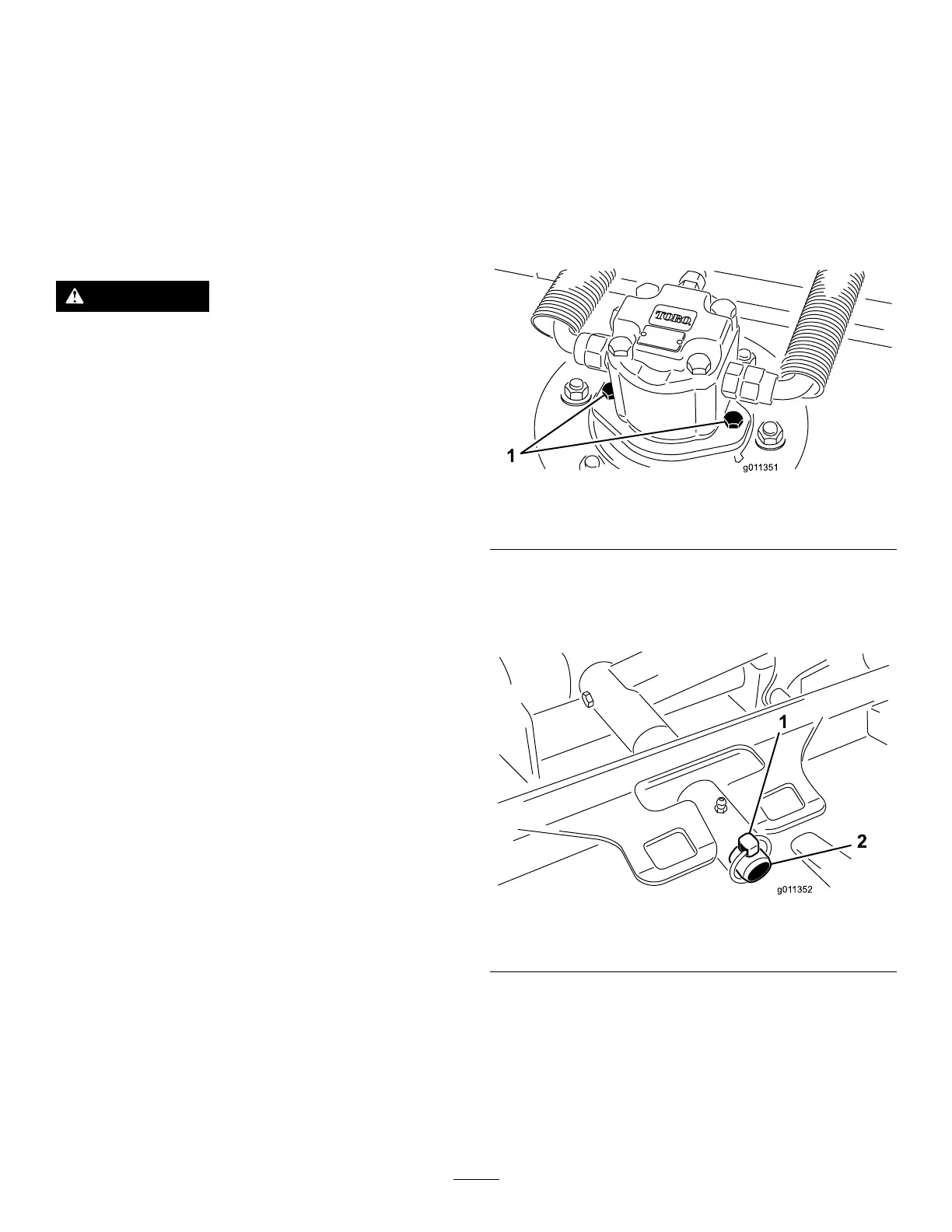

2.Disconnectandremovethehydraulicmotor

fromthecuttingunit(Figure78).Coverthetop

ofthespindletopreventcontamination.

g011351

Figure78

1.Motor-mountingscrews

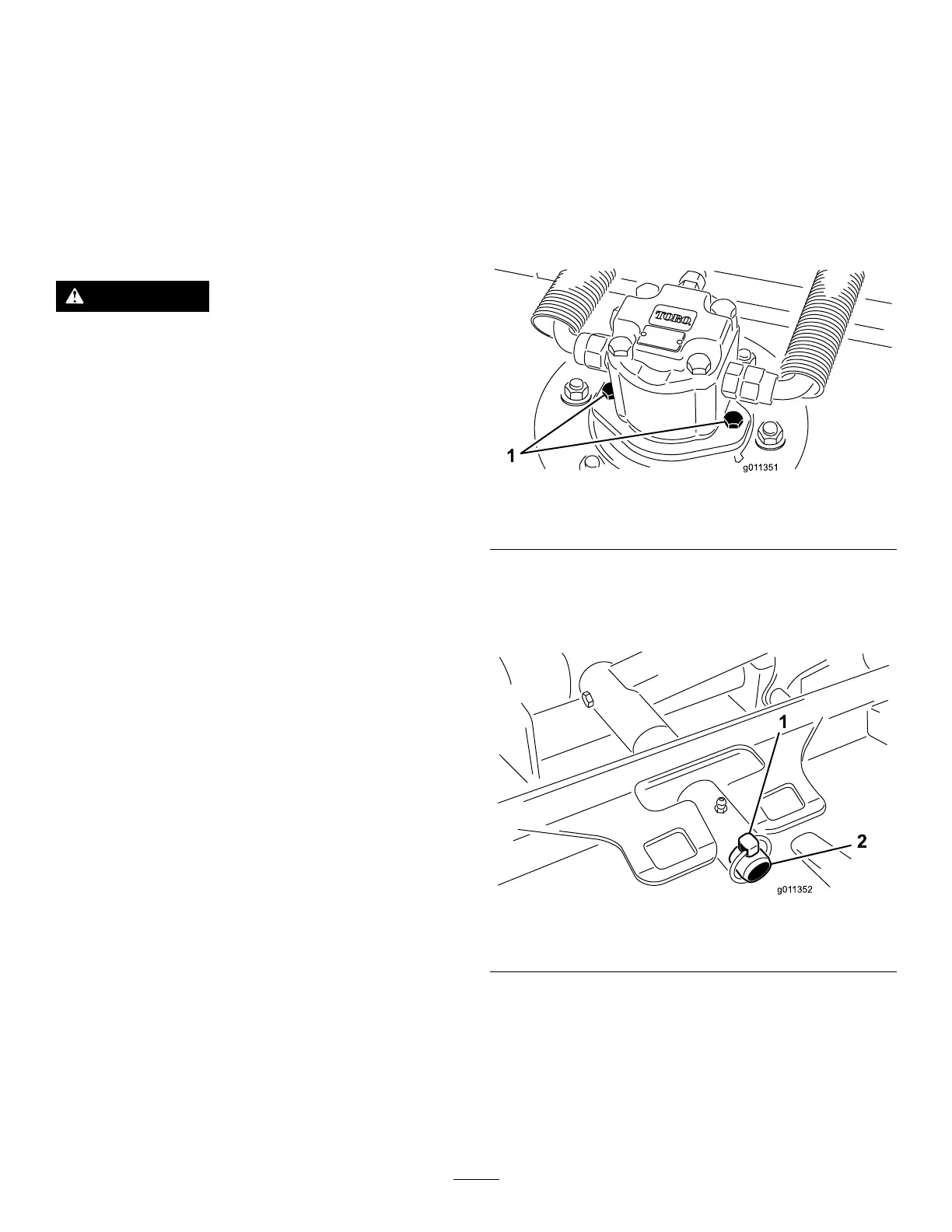

3.Removethelynchpin(forGroundsmaster4500

machines)orretainingnut(forGroundsmaster

4700machines)securingthecuttingunit-carrier

frametothelift-armpivotpin(Figure79).

g011352

Figure79

1.Lynchpin

2.Lift-armpivotpin

4.Rollthecuttingunitawayfromthemachine.

63

Loading...

Loading...