8.Rechecktheuidlevelwhiletheuidiswarm.If

required,adduidtothereservoiruntilitreachesthe

hotlevelofthebafe.

Note:Theuidlevelshouldbetothetopofthehot

levelofthebafe,whentheuidiswarm(Figure60).

9.Installthecaponthellerneck.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskinit

mustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistype

ofinjury.Gangrenemayresultifthisis

notdone.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesurethatallhydraulicuidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsare

tightbeforeapplyingpressuretohydraulic

system.

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst8hours

Every200hours

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

Important:Donotsubstituteanautomotiveoil

lter,orseverehydraulicsystemdamagemay

result.

3.Removethehydraulic-reservoircapandtemporarily

covertheopeningwithaplasticbagandarubberband

topreventallofthehydraulicuidfromdrainingout.

4.Locatethelterundertheenginebaseandplacea

drainpanunderthelter(

Figure61).

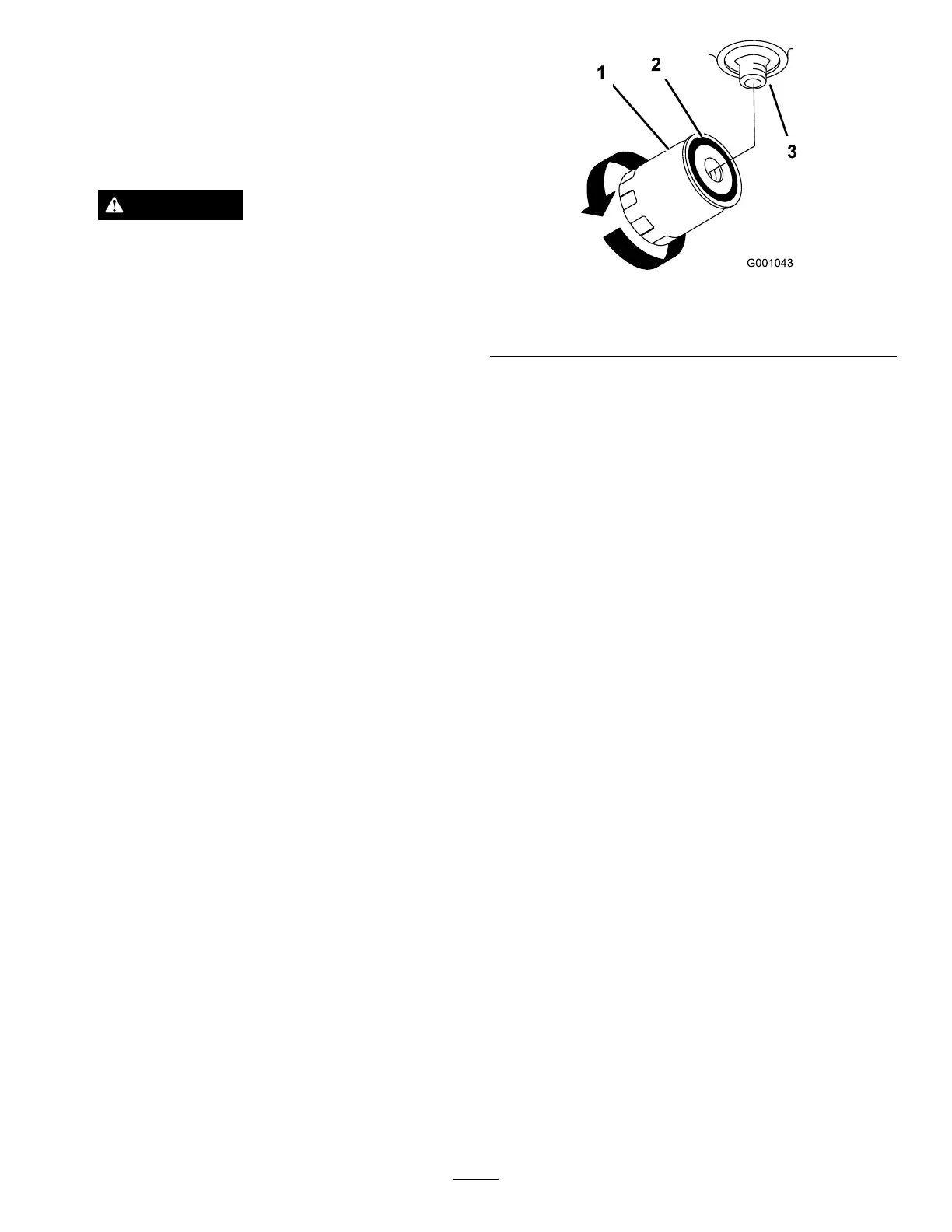

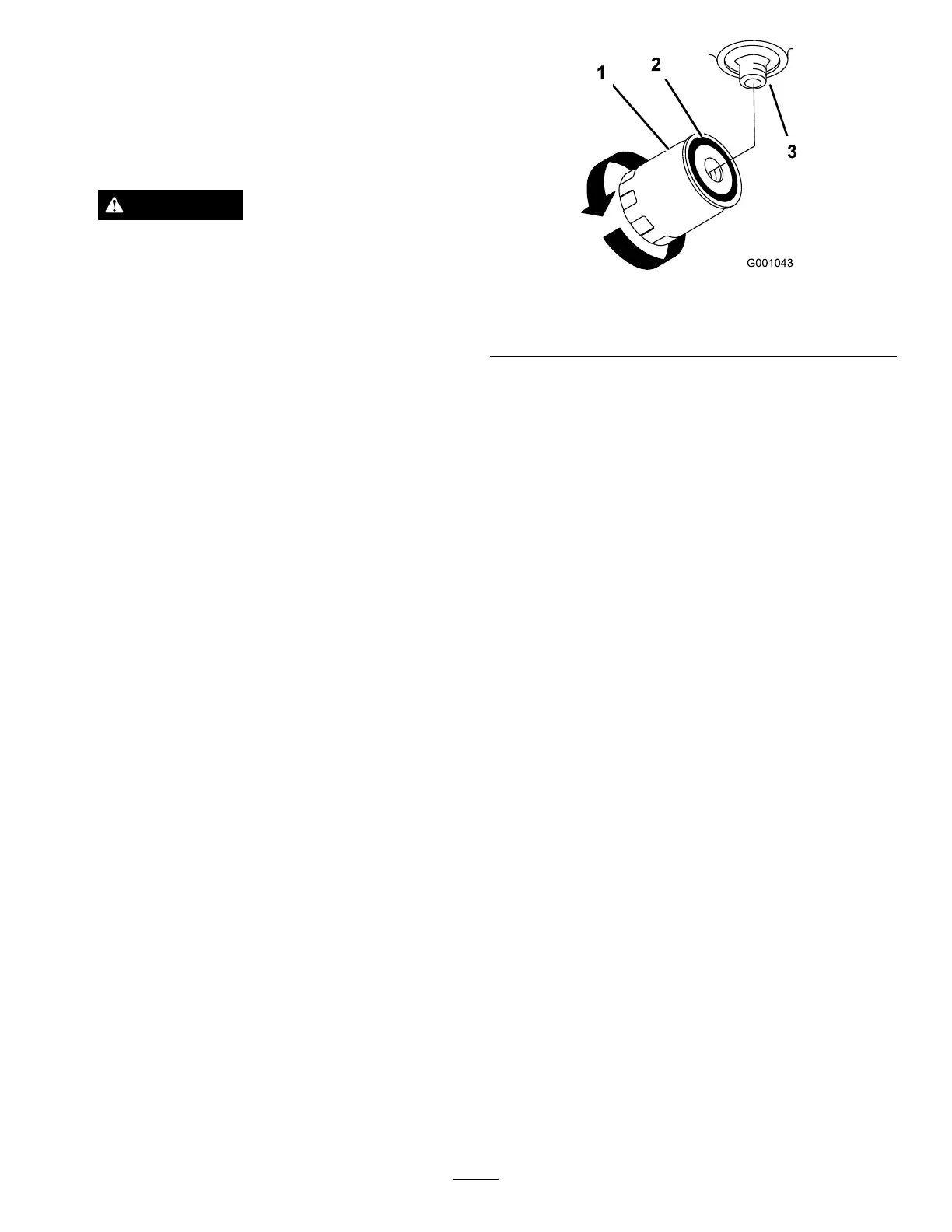

5.Removetheoldlterandwipethelter-adaptergasket

surfaceclean(Figure61).

Figure61

1.Hydrauliclter

3.Adapter

2.Gasket

6.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter.

7.Installthereplacementhydrauliclterontothelter

adapter.Donottighten.

8.Removetheplasticbagfromthereservoiropeningand

allowtheltertollwithhydraulicuid.

9.Whenthehydrauliclterisfull,turntheoillter

clockwiseuntiltherubbergasketcontactsthelter

adapter,thentightenthelteranadditional1/2turn

(

Figure61).

10.Cleanupanyspilleduid.

11.Ifthereisnouid,addMobil115W-50syntheticmotor

oiloranequivalentsyntheticoiltoapproximately6mm

(1/4inch)belowthetopofthereservoirbafe.

Important:Useoilspeciedorequivalent.Other

uidscouldcausesystemdamage.

12.Starttheengineandletitrunforabout2minutesto

purgeairfromthesystem.Stoptheengineandcheck

forleaks.Ifoneorbothwheelswillnotdrive,referto

BleedingHydraulicSystem.

13.Checkthelevelandadduid,ifrequired.Donot

overll.

BleedingtheHydraulicSystem

Thetractionsystemisselfbleeding,however,itmaybe

necessarytobleedthesystemiftheuidischangedorafter

workisperformedonthesystem.

Airmustbepurgedfromthehydraulicsystemwhenany

hydrauliccomponents,includingtheoillter,areremoved

oranyofthehydrauliclinesaredisconnected.Thecritical

areaforpurgingairfromthehydraulicsystemisbetweenthe

oilreservoirandeachchargepumplocatedonthetopof

eachvariabledisplacementpump.Airinotherpartsofthe

hydraulicsystemwillbepurgedthroughnormaloperation

oncethechargepumpisprimed.

1.DisengagethePTOandsettheparkingbrake.

42

Loading...

Loading...