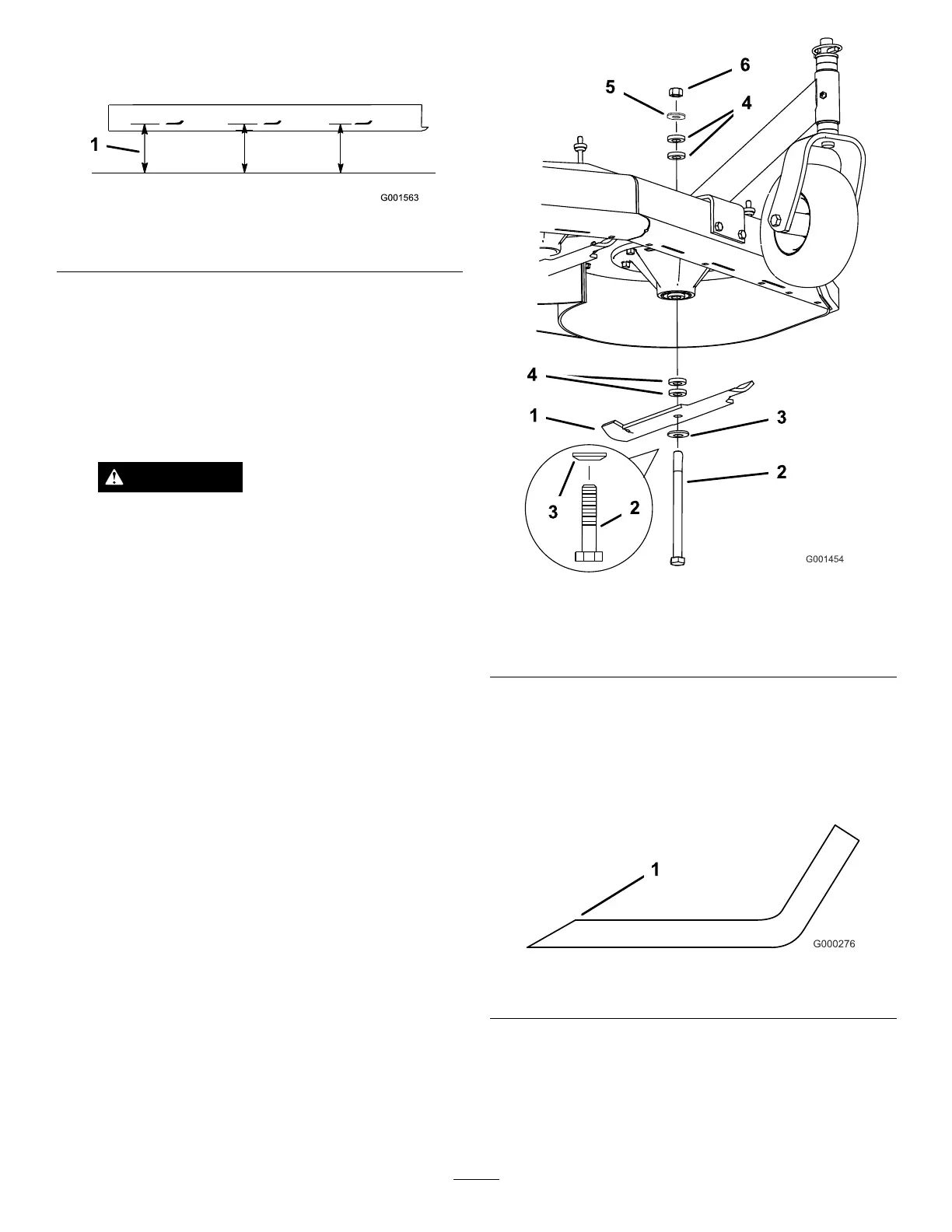

2.Measurefromalevelsurfacetothecuttingedge,

positionA,oftheblades(Figure66).Notethis

dimension.

Figure66

1.Measurefromthecuttingedgetoalevelsurface

3.Rotatetheoppositeendsofthebladesforward.

4.Measurefromalevelsurfacetothecuttingedgeofthe

bladesatthesamepositionasinstep1.Thedifference

betweenthedimensionsobtainedinsteps1and2

mustnotexceed3mm(1/8inch).Ifthisdimension

exceeds3mm(1/8inch),thebladeisbentandmustbe

replaced.RefertoRemovingtheBladesandInstalling

theBlades.

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Replacethebladesifyouhitasolidobjectorifthebladesare

outofbalanceorbent.Toensureoptimumperformanceand

continuedsafetyconformanceofthemachine,usegenuine

Tororeplacementblades.Replacementbladesmadebyother

manufacturersmayresultinnon-conformancewithsafety

standards.

1.Holdthebladeboltwithawrench.

2.Removethenut,bladebolt,curvedwasher,blade,

spacers,andthinwasherfromthespindle(Figure67).

Figure67

1.Blade

4.Spacer

2.Bladebolt5.Thinwasher

3.Curvedwasher

6.Nut

SharpeningtheBlades

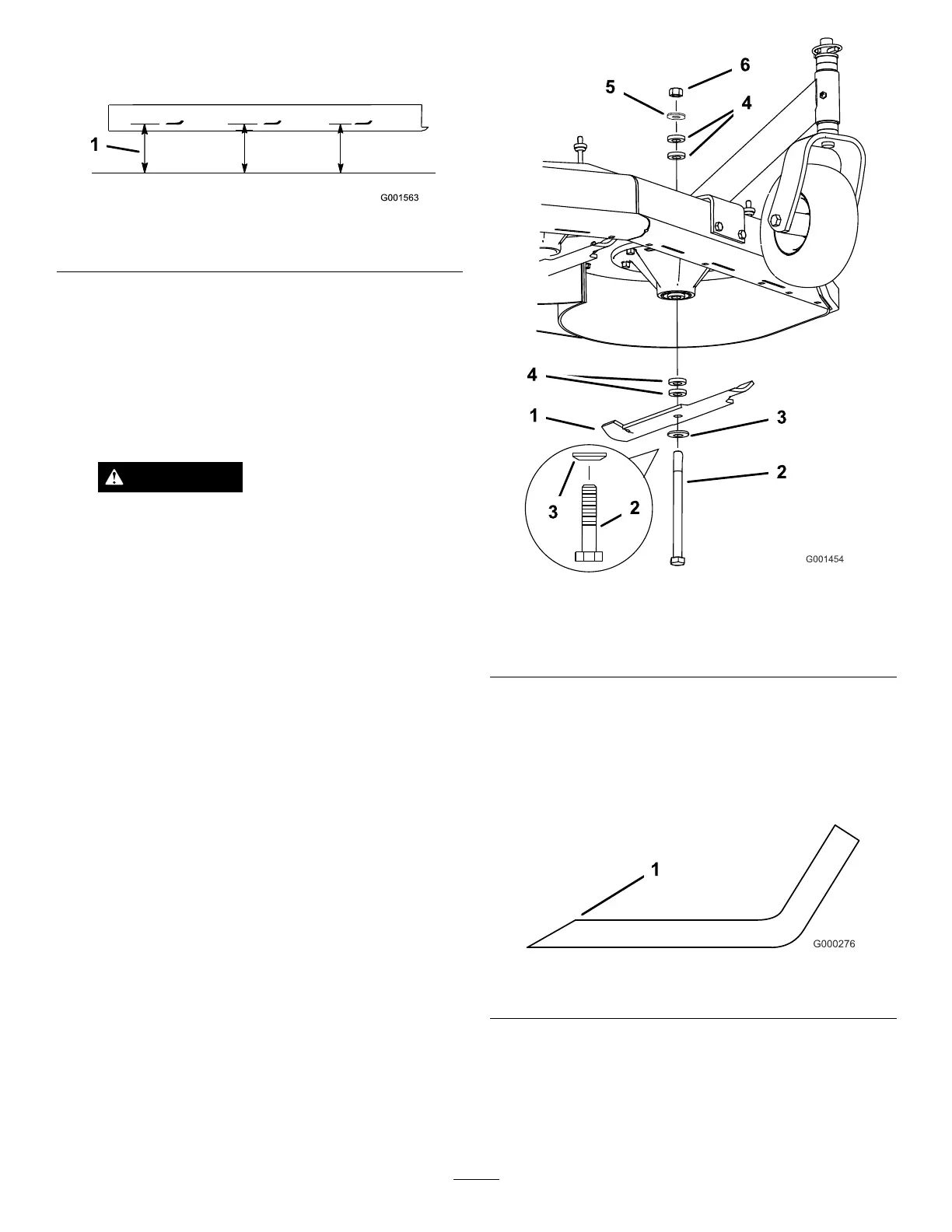

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure68).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

Figure68

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure69).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure69).Repeatthisprocedure

untilthebladeisbalanced.

45

Loading...

Loading...