2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineupontojackstandshigh

enoughtoraisethedrivewheelsofftheground.

4.Checkthehydraulicuidlevel.

5.Starttheengineandmovethethrottlecontroltothe

fullthrottleposition.Movethespeed-controlleverto

themiddlespeedpositionandplacethedrivelevers

intothedriveposition.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpbycarefully

rotatingthetireintheforwarddirection.

Note:Itisnecessarytolightlytouchthecharge-pump

capwithyourhandtocheckthepumptemperature.If

thecapistoohottotouch,turnofftheengine.The

pumpsmaybedamagedifthepumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinueto

thenextstep.

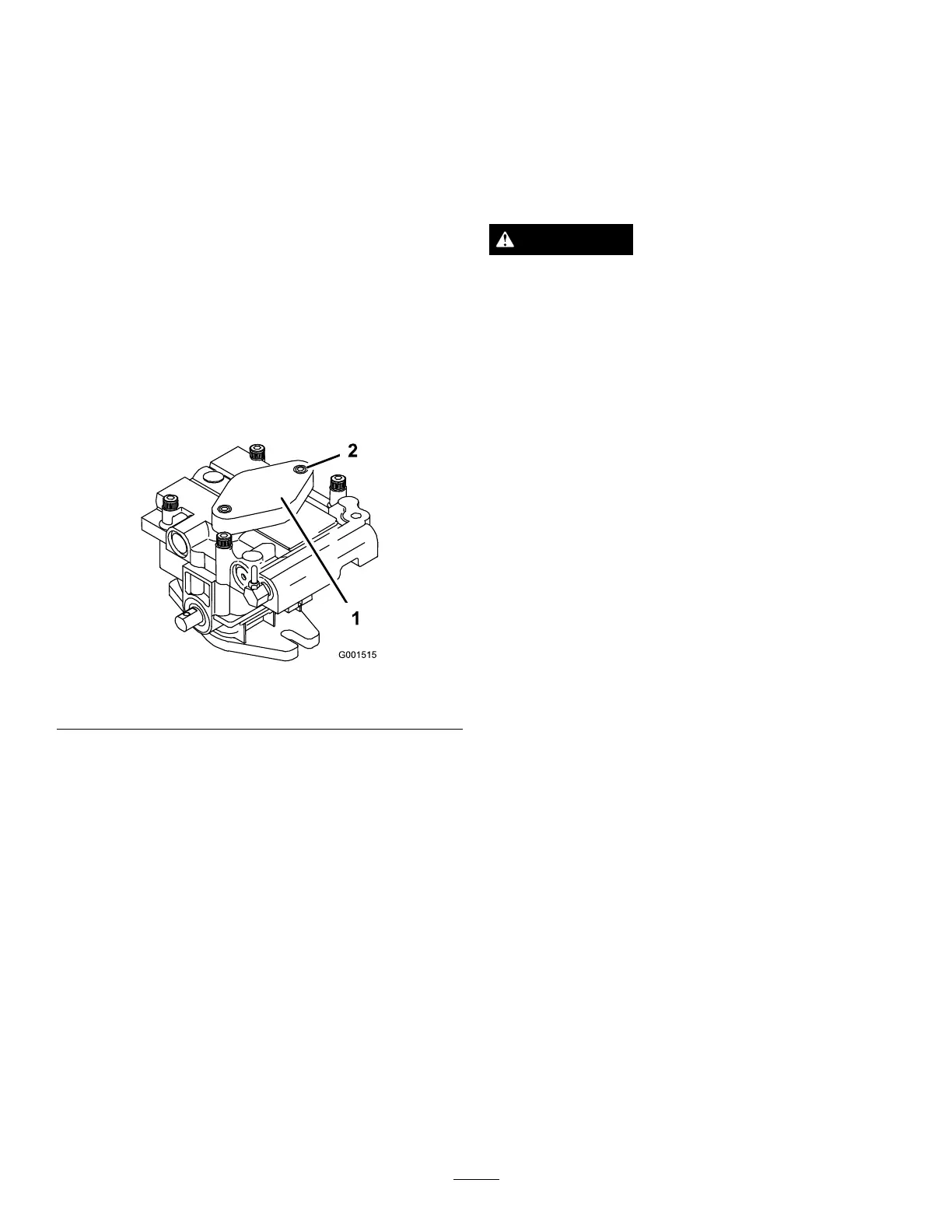

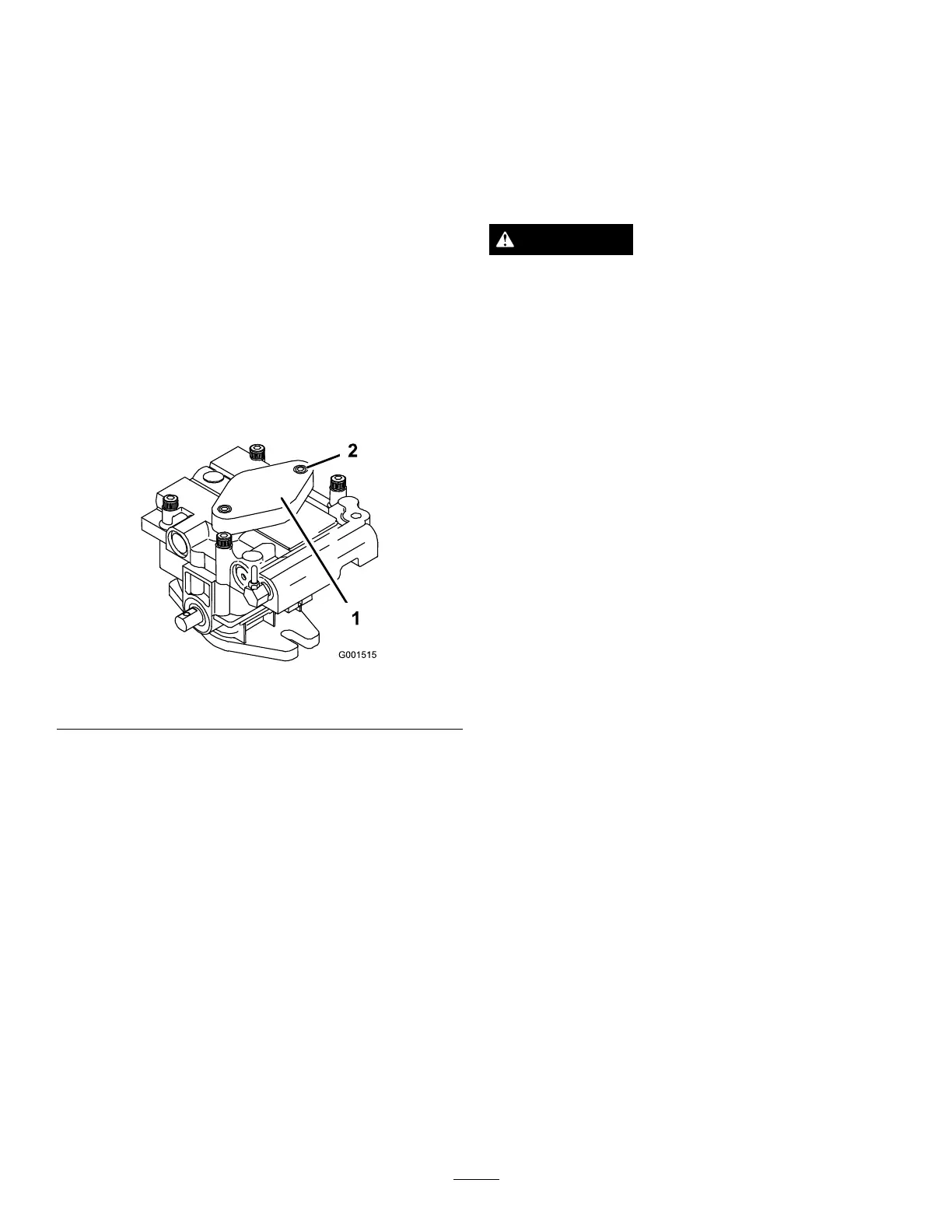

Figure62

1.Charge-pumpcap2.Socket-headscrew

6.Thoroughlycleantheareaaroundeachofthe

charge-pumphousings.

7.Toprimethechargepump,loosenthe2hex

socket-headcapscrews(Figure62)1-1/2turnsonly.

Makesureengineisnotrunning.Liftchargepump

housingupwardandwaitforasteadyowofoiltoow

outfromunderthehousing.Tightenthecapscrews.

Dothisforbothpumps.

Note:Thehydraulicreservoircanbepressurizedto

upto5psitospeedthisprocess.

8.Ifeitherdrivewheelstilldoesnotrotate,stopand

repeatsteps4and5ontherespectivepump.Ifthe

wheelsrotateslowly,thesystemmayprimeafter

additionalrunning.Checkthehydraulicuidlevel.

9.Allowthemachinetorunforseveralminutesafterthe

chargepumpsareprimedwiththedrivesysteminthe

full-speedposition.

10.Checkthehydrauliccontrollinkageadjustment.Refer

toAdjustingtheHydroControlLinkages.

CheckingtheHydraulicHoses

ServiceInterval:Every100hours

Checkhydraulichosesforleaks,loosettings,kinkedlines,

loosemountingsupports,wear,andweatherandchemical

deterioration.Makenecessaryrepairsbeforeoperating.

Note:Keeptheareasaroundthehydraulicsystemclean

fromgrassanddebrisbuildup.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskinit

mustbesurgicallyremovedwithinafewhours

byadoctorfamiliarwiththistypeofinjury.

Gangrenemayresultifthisisnotdone.

•Keepbodyandhandsawayfrompin-holeleaks

ornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Makesurethatallhydraulic-uidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

43

Loading...

Loading...