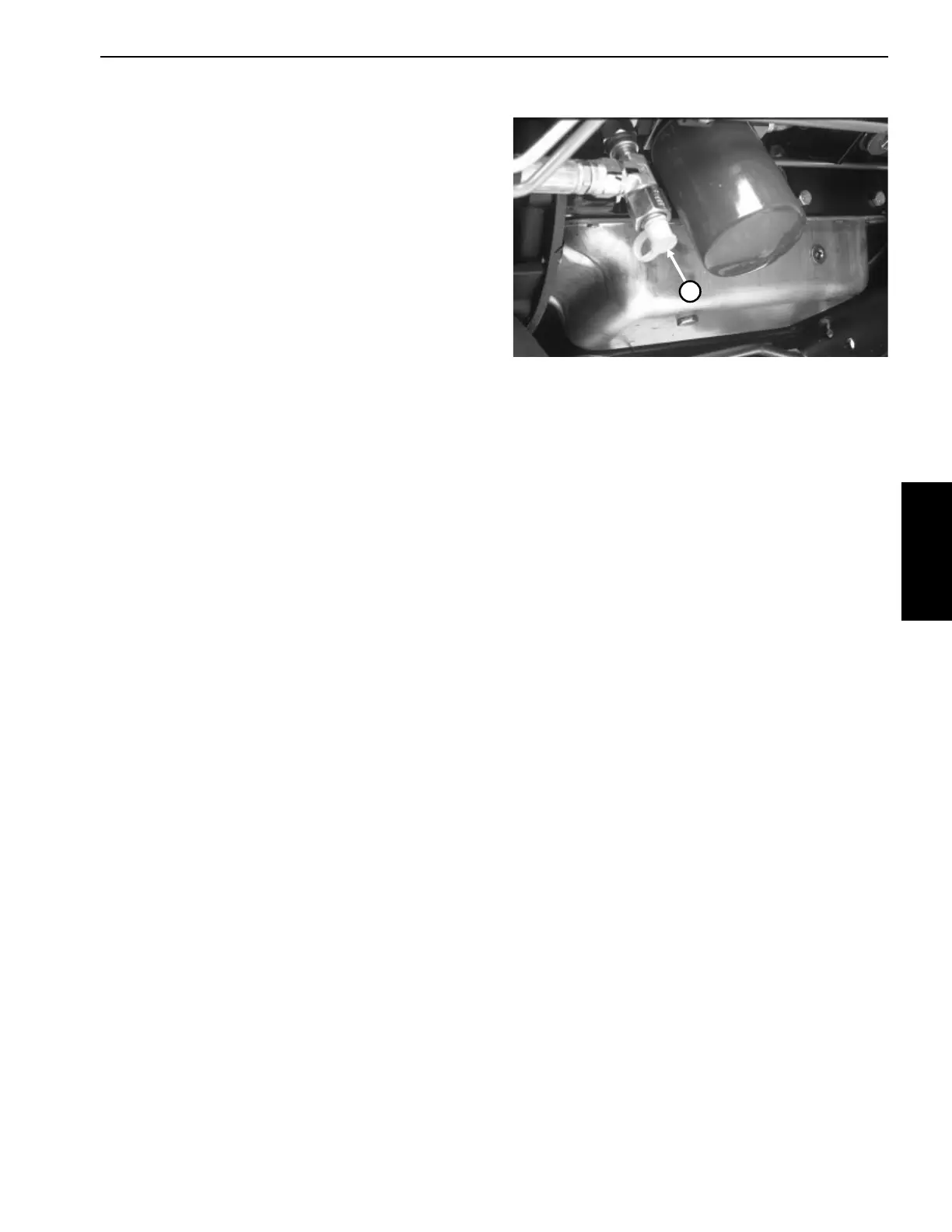

TEST NO. 6: Checking Charge Pressure

1. Make sure hydraulic oil is at normal operating tem-

perature by operating machine for approximately 10

minutes.

2. Lower cutting units, engage parking brake and stop

the en

gine.

3. Install a 1,000 PSI gauge onto the charge pressure

quick disc

onnect fitting.

4. Start the engine and position throttle at high idle

(3000 RPM).

TESTER READING TO BE 100

+25

/

–10

PSI.

5. If pressure is low, inspect charge relief valve and

valve seat.

6. Also take a gauge reading while operating the ma-

chin

e in forward and reverse. Start the engine and put

the throttle at full engine RPM. Apply the brakes and

push the traction pedal forward, then reverse. If pres-

sure is good under no load, but drops below specifica-

tion when under traction load, the piston pump and/or

motor should be suspected of wear and inefficiency.

When the pump and/or motor is worn or damaged the

charge pump may not able to keep up with the internal

leakage.

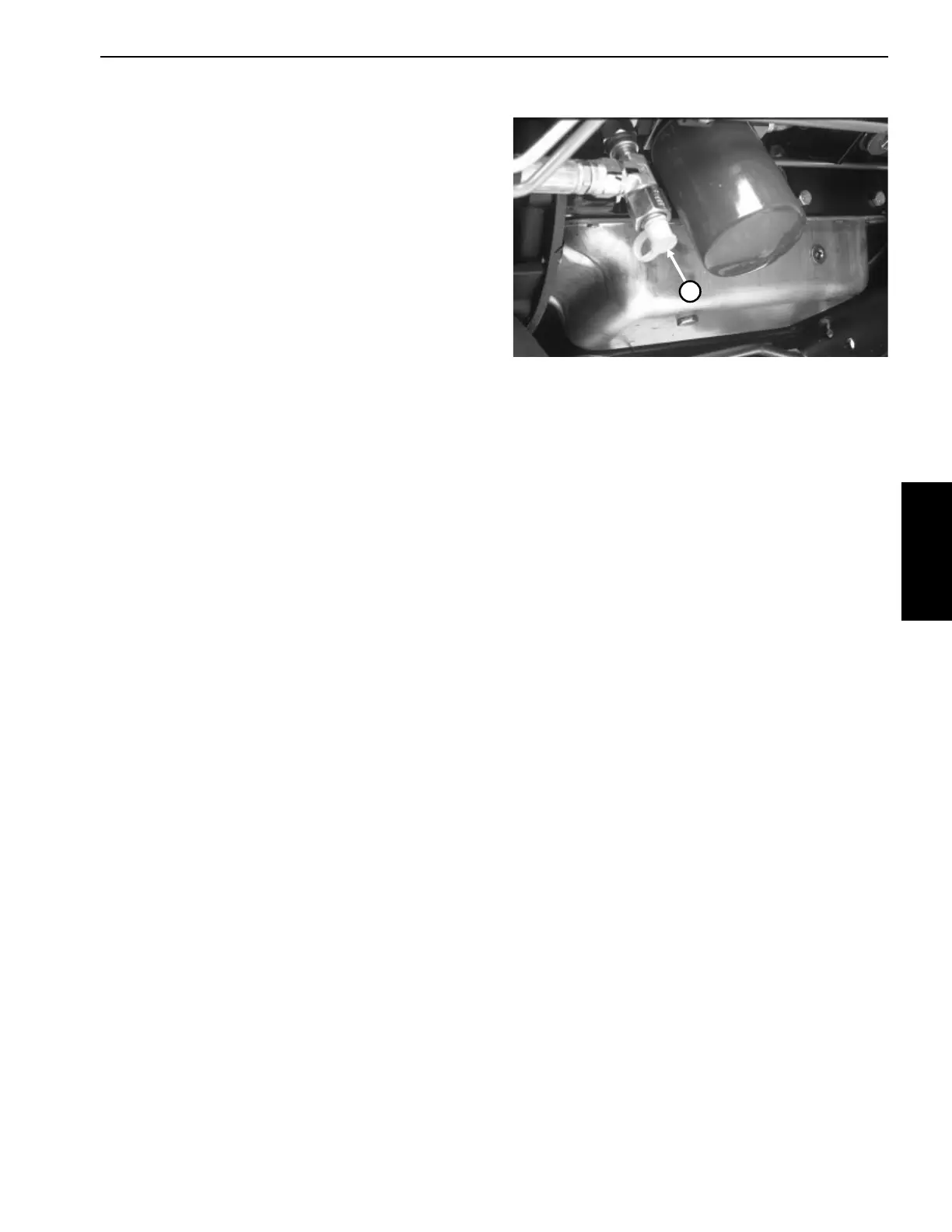

1

Figure 15

1. Charge pressure test port

Hydraulic System

Groundsmaster

®

455-D

Page 4 - 25

Rev. C

Testing

Loading...

Loading...