Groundsmaster 4300--D Hydraulic SystemPage 4 -- 101

WARNING

Make sure that cutting decks are fully lowered

before loosening hydraulic lines, cartridge

valves or plugs from lift control manifold. If

decks are not fully lowered as manifold compo-

nents are loosened, decks may drop unexpect-

edly.

5. Disconnect hydraulichoses and linesfrom fittingsin

manifold. Allow lines to drain into a suitable container.

Remove and discard O--rings.

6. Put caps or plugs on disconnected lines and fittings

to prevent contamination.

7. Label all solenoid coil wire harness leads for as-

semblypurposes.Unplugwireharnessleadsfromsole-

noid coils on manifold.

8. Remove two (2) flange head screws that secure

manifold to machine frame.

9. Remove lift control manifold from machine.

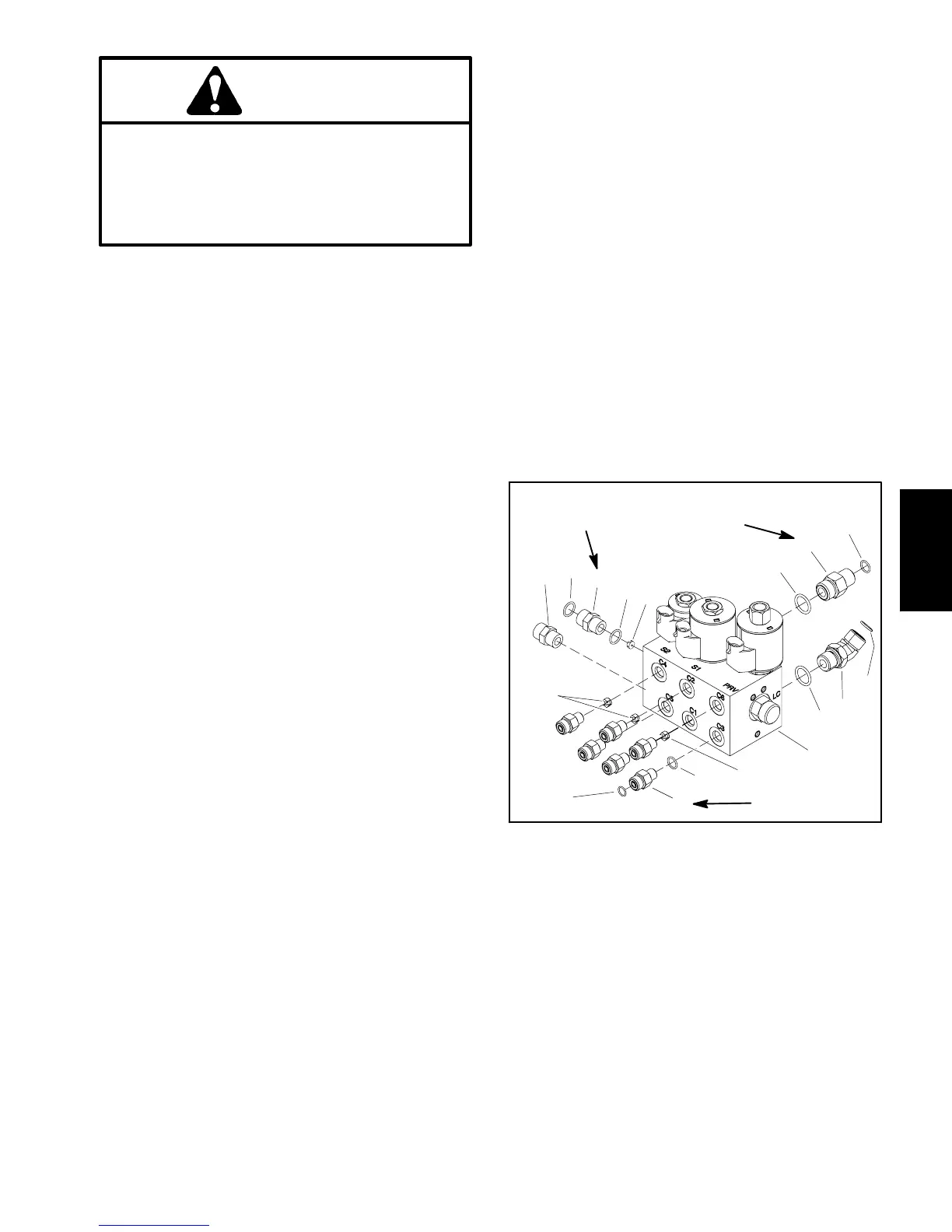

IMPORTANT: A flow control orifice is placed be-

neath several hydraulic fittings on the lift control

manifold (Fig. 91). The lift manifold uses two (2) dif-

ferentorificesizes.Iffittingsareremovedfromman-

ifoldandanorificeisinthemanifoldport,makesure

toremoveorifice and label itspositionforassembly

purposes.

10.Ifnecessary,remove hydraulicfittingsfrommanifold

(Fig. 91). Discard any removed O--rings. Locate, re-

trieve and label orifice from manifold port (if equipped).

Installation (Fig. 90)

1. If fittings were removed from manifold (Fig. 91):

A. Lubricate new O--rings with clean hydraulic oil.

Install lubricated O--rings on fittings.

IMPORTANT: Wheninstallingorificeinmanifold,

make sure that orifice is flat in the base of the fit-

ting cavity. Manifold damage is possible if the

orifice is cocked in the cavity.

B. For manifold ports with orifice, place correct ori-

fice in port with the orifice slot facing out.

C. Install fittings into manifold. Torque fittings to

torque values identified in Figure 91.

2. Position lift control manifold to frame. Install two (2)

flange head screws but do not fully tighten.

3. Remove caps and plugs from disconnected lines

and fittings.

4. Lubricate and install new O--ring(s) on manifold fit-

tings. Connect hydraulic lines to hydraulic manifold fit-

tingsandproperlytightenallconnections(seeHydraulic

Hose and Tube Installation in the General Information

section of this chapter).

5. Securehydraulicmanifoldtoframebytighteningtwo

(2) flange head screws.

6. Connect wire harness leads to solenoid coils on

manifold using labels placed during removal.

7. Checkoillevel inhydraulicreservoirandaddcorrect

oil if necessary.

8. Follow Hydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

1. Lift control manifold

2. Straight fitting (2 used)

3. O--ring

4. O--ring

5. Orifice (0.030)

6. Orifice (0.046) (3 used)

7. Straight fitting (6 used)

8. O--ring

9. O--ring

10. Straight fitting

11. 45

o

fitting

12. O--ring

Figure 91

(68 N--m)

50 ft--lb

(27 N--m)

20 ft--lb

(27 N--m)

20 ft--lb

1

5

3

4

7

6

2

6

2

3

4

9

8

9

11

12

10

Hydraulic

System

Loading...

Loading...