Groundsmaster 4300--D Hydraulic SystemPage 4 -- 109

CAUTION

Beforeopeninghydraulicsystem,operateallhy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

RelievingHydraulicSystemPressurein theGen-

eral Information section of this chapter.

7. Disconnect hydraulic lines from steering control

valve. Allow lines to drain into a suitable container.

8. Put caps or plugs on disconnected lines and fittings

to prevent contamination.

9. Loosen and remove remaining two (2) socket head

screws and flange nuts that secure steering column to

machine.

10.Remove steering column and steering control valve

assembly from machine.

11.Loosenandremovefour(4)socketheadscrewsthat

secure steering control valve to steering column.

12.Remove steering control valve from steering col-

umn.

13.Ifnecessary,removefittingsandO--ringsfromsteer-

ing control valve. Discard all removed O--rings.

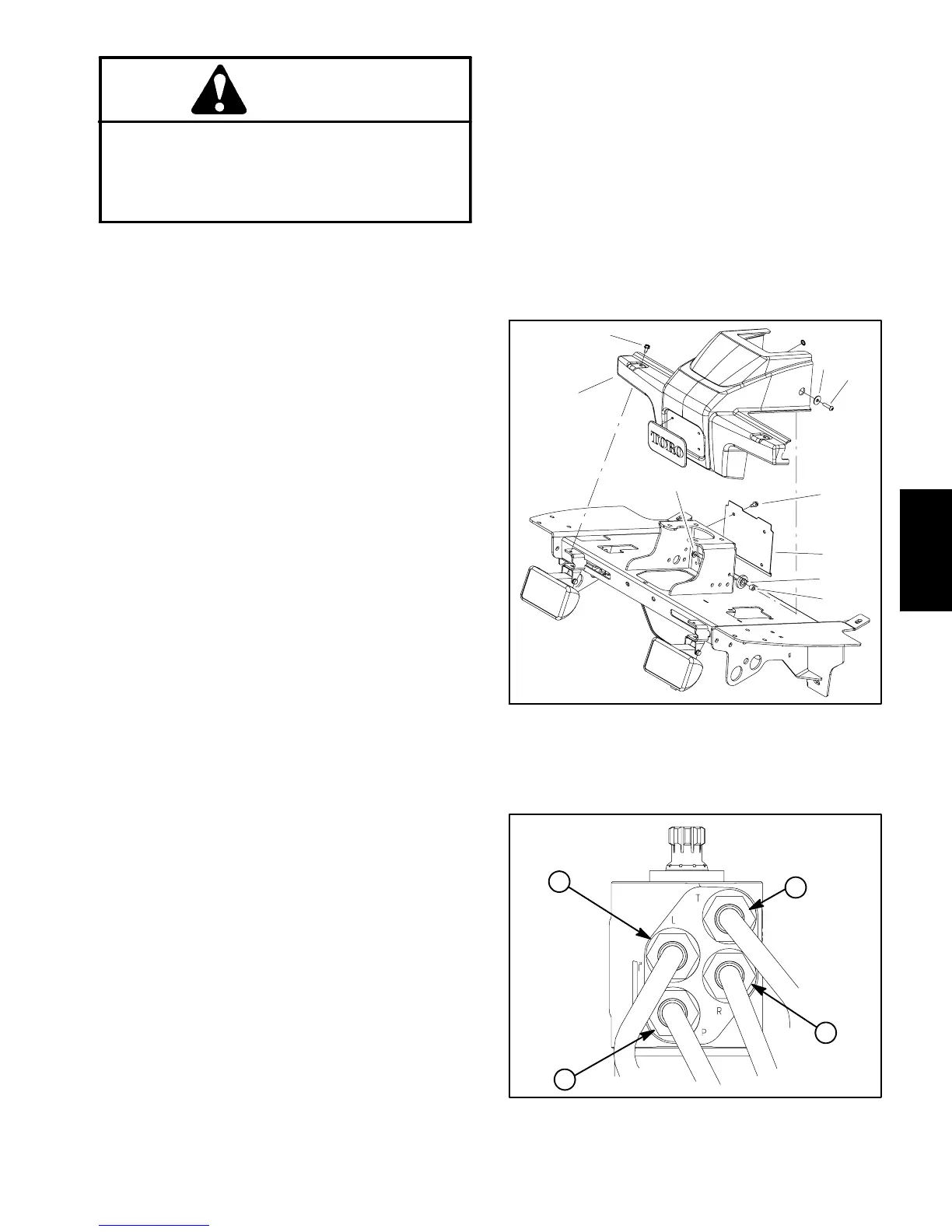

Installation (Fig. 97)

1. If fittings were removed, lubricate new O--rings with

clean hydraulic oil and install fittings to steering control

valve (see Hydraulic Fitting Installation in the General

Information section of this chapter).

2. Apply antiseize lubricant to splines of steering con-

trol valve shaft.

3. Slide steering control valve shaft into steering col-

umn universal joint. Position control valve withportsto-

ward front of machine. Secure steering control valve to

steering c olumn with four (4) socket head screws.

Torque screws in a criss--cross pattern from 84 to 120

in--lb (9.5 to 13.5 N--m).

4. Position steering column assembly to machine. Se-

cure steering column in place with two (2) socket head

screws and flange nuts at rear two mounting holes.

5. Remove caps and plugs from disconnected lines

and fittings.

6. Lubricate new O--rings and connect hydraulic lines

tofittingsonsteeringcontrolvalve.Tightenconnections

(seeHydraulicHoseandTube InstallationintheGener-

al Information section of this chapter).

7. Position steeringcolumnbrace(item 13)tomachine

and secure with four (4) screws and flange nuts.

8. Slide rubber bellows to bottom of steering column.

9. Place r ubber bushings and spacers into holes of

shroud (Fig. 98). Position shroud in place and secure

with removed fasteners.

10.Checkoillevel inhydraulicreservoirandaddcorrect

oil if necessary.

11.Follow H ydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

1. Washer (2 used)

2. Screw (2 used)

3. Washer head screw

4. Platform shroud

5. Lock nut (2 used)

6. Cover plate

7. Bushing (2 used)

8. Spacer (2 used)

Figure 98

3

4

1

2

5

3

6

7

8

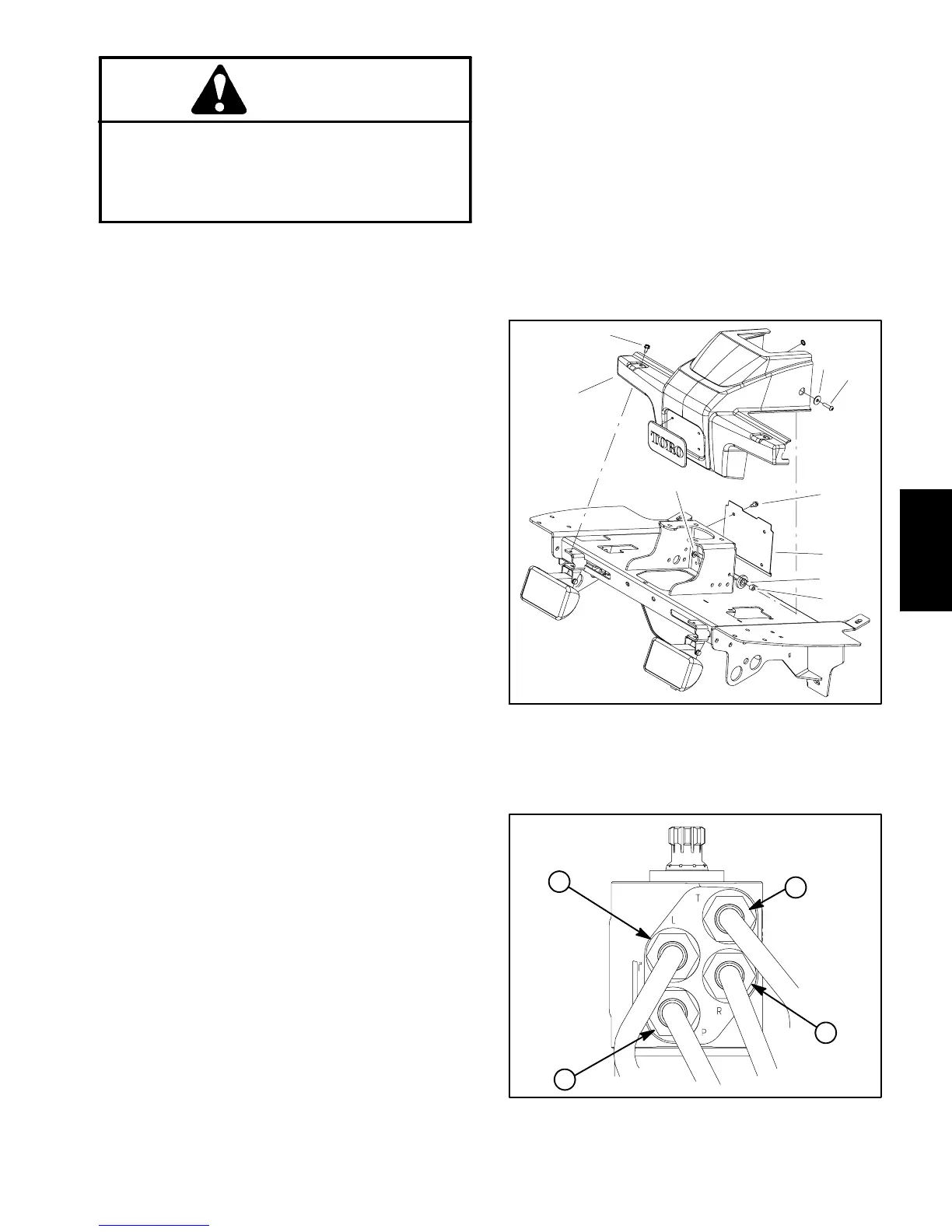

Figure 99

L

P

R

T

Hydraulic

System

Loading...

Loading...