Groundsmaster 4300--D Hydraulic SystemPage 4 -- 113

Removal (Fig. 101)

1. Park the machine on a level surface, engage the

parking brake, lower the cutting decks and stop the en-

gine. Remove the key from the ignition switch.

2. Read the General Precautions for R emoving and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

CAUTION

Beforeopeninghydraulicsystem,operateallhy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

RelievingHydraulicSystemPressurein theGen-

eral Information section of this chapter.

3. Label all hydraulic connections for assembly pur-

poses. Thoroughly clean hydraulic hose ends prior to

disconnecting hoses from the steering cylinder.

4. Disconnect hydraulic hoses from steering cylinder.

5. Putcapsorplugsondisconnectedhosesandfittings

to prevent contamination.

6. Removetwo(2)jamnuts(item16)thatsecuresteer-

ing cylinder to axle. Remove cotter pin (item 20) and

slottedhex nut(item29) thatsecuresteering cylinderto

RH drag link.

7. Separate s teering cylinder ball joints from axle as-

sembly and remove steering cylinder from machine.

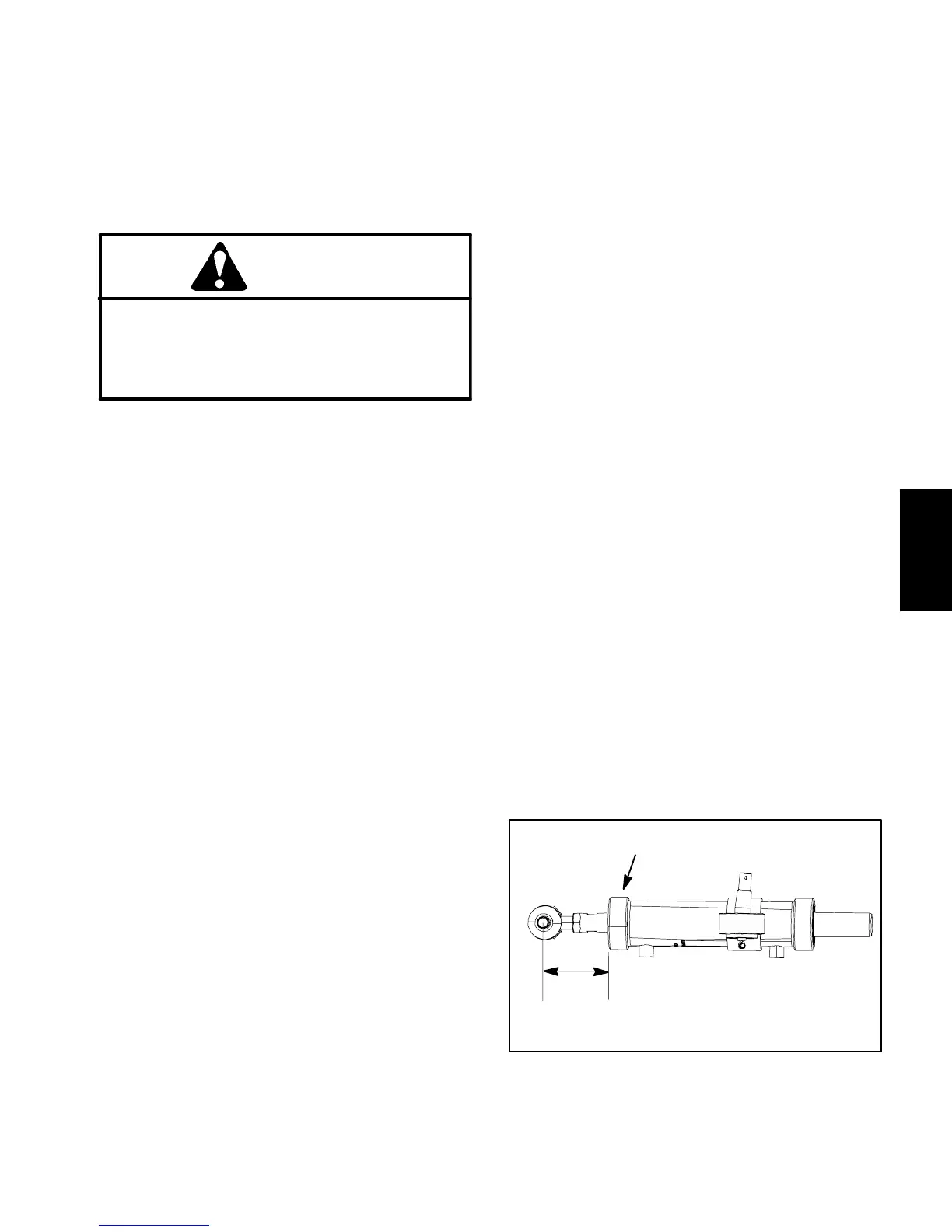

8. If necessary, remove ball joints from steering cylin-

der barrel and shaft. If ball joint is to be removed from

cylinder shaft, fully retract cylinder shaft and measure

distancefromcylinderfrontheadtocenterofballjointto

easeinstallationofballjointintocylindershaft(Fig.102).

9. If hydraulic fittings are to be removed from steering

cylinder, mark fittingorientation to allowcorrect assem-

bly. Remove fittings from steering cylinder and discard

O--rings.

Installation (Fig. 101)

1. Ifhydraulicfittingswereremovedfromsteeringcylin-

der,lubricatenewO--r ings withcleanhydraulicoil,posi-

tion O--rings to fittings and install fittings into steering

cylinder ports (see Hydraulic Fitting Installation in the

GeneralInformation section ofthis chapter).Make sure

that fittings are orientated correctly.

2. Ifremoved,pressballjointintobarrelandsecurewith

retaining ring.

3. If ball joint wasremoved from cylinder shaft, fullyre-

tractcylindershaft andthreadballjoint intoshaftso that

distancefromcylinder frontheadtocenter ofballjointis

as measured during removal process. Tighten jam nut.

4. Thoroughly clean tapers on ball joints and axle as-

sembly.

5. Position steering cylinder to machine.

6. Secure steering cylinder to axle with jam nuts (item

16).Tightenfirstjamnutandthen,whileholdingfirstjam

nut with wrench, tighten second jam nut.

7. Secure steering cylinder to RH drag link with slotted

hex nut (item 29). Install cotter pin (item 20).

8. Remove caps and plugs from hydraulic hoses and

fittings.

9. Lubricate and install new O--rings on steering cylin-

der fittings. Correctly connect hydraulic hoses to steer-

ing cylinder (see Hydraulic Hose and Tube Installation

in the General Information section of this chapter).

10.Checkoillevel inhydraulicreservoirandaddcorrect

oil if necessary.

11.Lubricate s teering cylinder ball joint grease fittings.

12.Follow Hydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

13.Check that steering cylinder does not contact the

axle or frame as cylinder moves from fully retracted to

fully extended. Also, check that distance between the

drag linksand steering stops are equalon both sides of

themachine.Ifnecessary,adjustlocationofballjointon

cylinder shaft.

Figure 102

MEASURE DISTANCE

FOR ASSEMBLY PURPOSES

FRONT HEAD

Hydraulic

System

Loading...

Loading...