Groundsmaster 4300--D Page 6 -- 9 Chassis

6. Remove return spring and clevis pin that secure

brakecabletobrakeactuatorlever.Positionbrakecable

end away from lever.

7. Remove brake drum.

IMPORTANT: DONOThitwheel hub,pullerorwheel

motor with a hammer during wheel hub removal or

installation. Hammering may cause damage to the

wheel motor.

8. Makesurethatlocknut onwheel motorshaftisloos-

ened at least two (2) turns. Use hub puller (see Special

Tools) to loosen wheel hub from wheel motor.

9. Remove lock nut and wheel hub from motor shaft.

Discard lock nut. Locate and retrieve square key.

NOTE: Ifdesired,thecomplete brakeassemblycanbe

removed from the machine for disassembly (see step

12).

10.Remove upper and lower shoe springs from brake

shoes.

11.Remove s hoe hold down cups and hold down

springs. Removebrake shoes andhold down pinsfrom

backing plate.

12.If necessary, remove brake backing plate from ma-

chine by loosening and removing four (4) cap screws

(item 26) and lock nuts (item 27).

Installation (Fig. 6)

1. Remove rust and debris from all brake parts with a

wire brush prior to installation. Clean all parts. Inspect

brake shoe contact surfaces of the brake drum for ex-

cessive wear. Replace any worn or damaged parts.

2. If brake backing plate was removed from machine,

secure backing plate to brake bracket with four (4) cap

screws (item 26) and lock nuts (item 27).

3. Lightlylubricatebrakeshoepivotpointswithgeneral

purpose grease.

4. Position one brake shoe to the backing plate. Install

brake hold down pin and secure with hold down spring

and cup. Repeat for second brake shoe.

5. Installupper andlowershoe springstobrakeshoes.

Make sure that brake s hoes are properly positioned to

pivot and actuator points.

IMPORTANT: Before wheel hub is installed, thor-

oughly clean tapers of wheel hub and wheel motor

shaft. Make sure that tapers are free of grease, oil

and dirt.Do not useantiseize lubricant when instal-

ling wheel hub.

6. Mount square key in the w heel motor shaft, then

install the wheel hub onto the wheel motor shaft.

IMPORTANT: Do not reuse lock nut that secures

wheelhubtowheelmotorafterithasbeenremoved.

7. Install new lock nut (item 17) onto the wheel motor

shaft to secure wheel hub to motor shaft.

8. Install brake drum.

9. Positionbrakecableendtobrakeactuatorlever.Se-

cure cable to actuator lever with clevis pin and return

spring.

10.Install front wheel assembly (see Wheel Installation

in this section).

11.Check and adjust brakes.

12.Lower machine to ground.

13.Torque lug nuts evenly in a crossingpatternfrom 70

to 90 ft--lb (95 to 122 N--m). Torque lock nut (item 17)

that secures wheel hub from 315 to 385 ft--lb (427 to

521 N--m).

CAUTION

After servicing the brakes, always check the

brakes in a wide open, level area that is free of

other persons and obstructions.

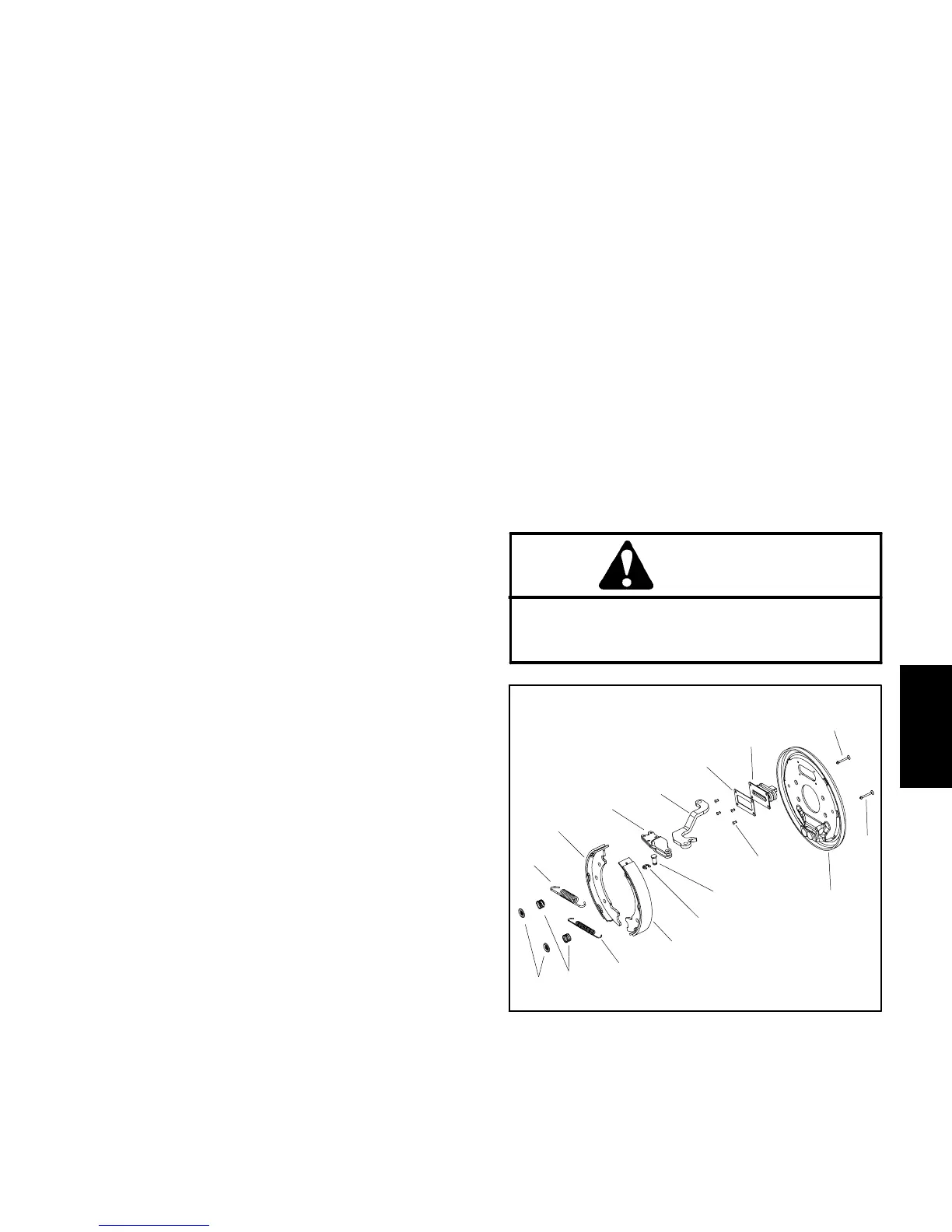

1. Backing plate

2. Rivet (4 used)

3. Clevis pin

4. Retaining ring

5. Brake shoe

6. Lower shoe spring

7. Hold down spring

8. Hold down cup

9. Upper shoe spring

10. Brake actuator

11. Actuator lever

12. Back--up plate

13. Boot

14. Hold down pin

Figure 7

10

2

3

1

4

5

6

8

9

7

5

11

12

13

14

14

Chassis

Loading...

Loading...