Groundsmaster 4300--D Page 6 -- 21 Chassis

IMPORTANT: When removing the seat suspension,

make sure to support the control arm to prevent

damage to the throttle cable, control arm electrical

components and control arm wiring harness.

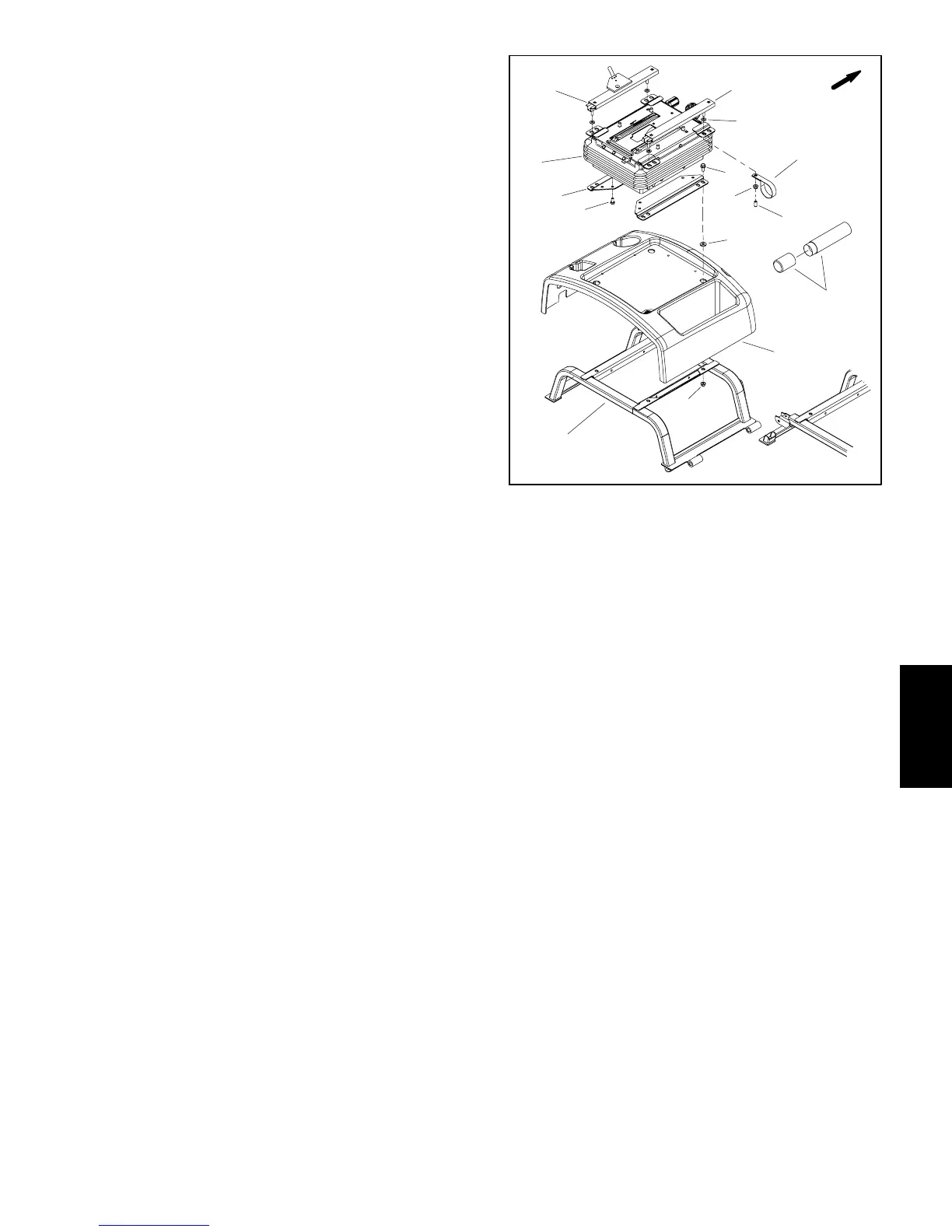

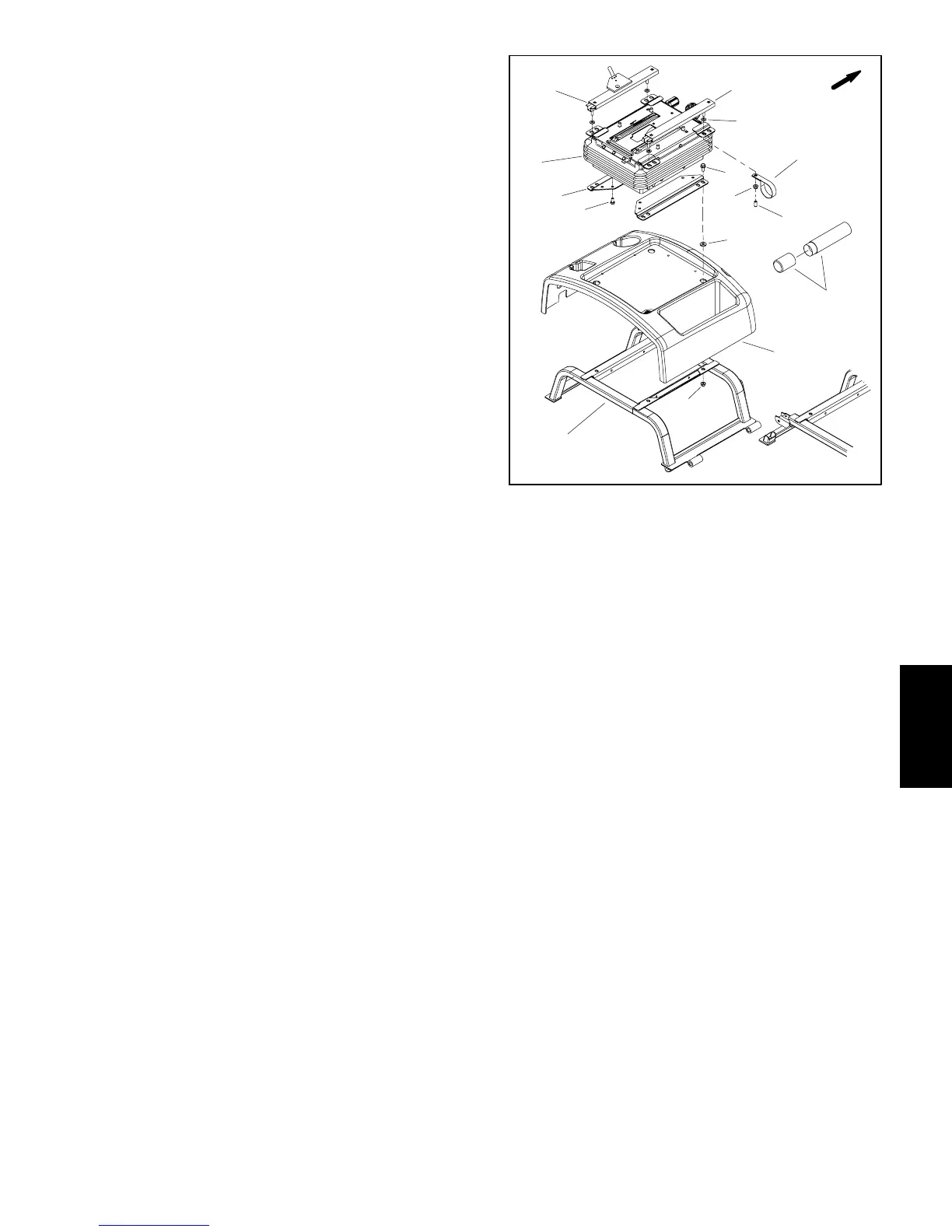

Removal (Figs. 18 and 19)

1. Park machine on a level s urface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch.

2. Disconnect negative batterycablefrom battery (see

Battery Service in the Service and Repairs section of

Chapter 5 -- Electrical System).

3. Remove seat from machine(see Operator SeatRe-

moval in this section).

IMPORTANT: Take care to not damage the throttle

cableorelectricalharnesswhenremovingseatsus-

pension from machine.

4. Tilt and support seat frame to allow access to seat

suspension fasteners.

5. Support seat suspension to prevent it from falling.

Remove four (4) flange head screws (Figure 19 item 8)

and flangenuts (Figure 19item 5)that secureseat sus-

pension to seat frame.

6. Removeseatsuspensionfrommachine.Locateand

retrieve four (4) spacers (Figure 19 item 7) from be-

tween seat suspension and seat frame.

7. Remove seat suspension components as needed

using Figures 18 and 19 as guides.

Installation (Figs. 18 and 19)

1. Installall removedseatsuspension componentsus-

ing Figures 18 and 19 as guides.

IMPORTANT: Take care to not damage the throttle

cableorelectricalharnesswheninstallingseatsus-

pension to machine.

2. Positionseatbasecoverandfour(4)spacers(Figure

19 item 7) to seat frame.

3. Position seat suspension to seat frame and secure

with four (4) flange head screws (Figure 19 item 8) and

flangenuts( Figure19item5).Useforwardholesinseat

brackets to mount suspension.

4. Install seat to machine (see Operator Seat Installa-

tioninthissection). Makesure toconnectharnesselec-

trical connector to the seat switch.

5. Connect negative battery cable to battery (see Bat-

teryServiceintheServiceandRepairssectionofC hap-

ter 5 -- Electrical System).

1. Seat suspension

2. Seat bracket (2 used)

3. Screw (4 used)

4. Seat frame

5. Flange nut (8 used)

6. Seatbase cover

7. Spacer (4 used)

8. Flange screw (4 used)

9. Cap (4 used)

10. Manual tube

11. R--clamp (2 used)

12. Flat washer (4 used)

13. Seat adjuster

14. Seat adjuster w/latch

Figure 19

1

2

4

3

5

6

7

8

FRONT

5

9

10

11

12

13

14

Chassis

Loading...

Loading...