Groundsmaster 4300--D Page 6 -- 25 Chassis

C. Remove screw that secures r--clamp to lift arm.

Position r--clamp and hydraulic hoses away from lift

arm.

D. Pivot lift cylinder rod end away from lift arm.

4. Remove fasteners that secure bridge plate (item 1)

and bulkhead bracket (item 16) to machine. Position

bulkhead bracket with attached hydraulic hoses away

from lift arm. Remove bridge plate.

5. Slide rear lift arm from lift arm pivot shaft.

6. Inspect flange bushings in lift arm for wear or dam-

age. If necessary, replace bushings:

A. Use bushing removal tool to extract both flange

bushings from the lift arm. Take care to not damage

the lift arm bore.

B. Clean the insideof the boreto remove anydirtor

foreign material.

C. Applygreasetotheinsideandoutside ofthenew

flange bushings.

D. Use an arborpress to install the bushingsinto lift

arm. Bushings should be pressed until bushing

flange is against lift arm bore.

E. After bushing installation, make sure that lift arm

slides easily onto pivot shaft. If binding is noted, lo-

cate and correct source of binding.

7. If necessary, remove cap screw that secures pivot

shaft (item 11) in lift arm. Remove pivot shaft from lift

arm.

8. Ifnecessary,removerollpin(item13)andliftarmpiv-

ot shaft (item 9) from frame. Discard roll pin.

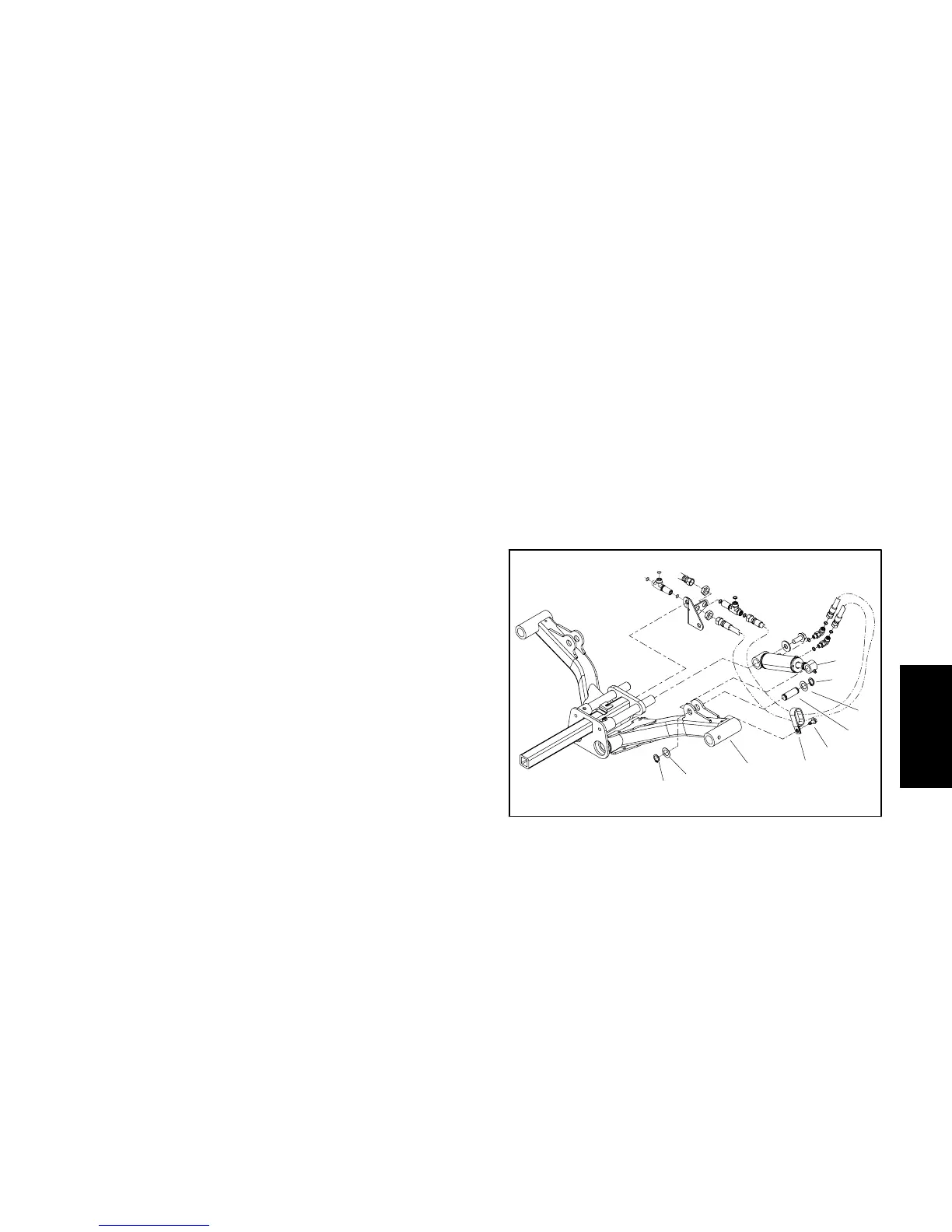

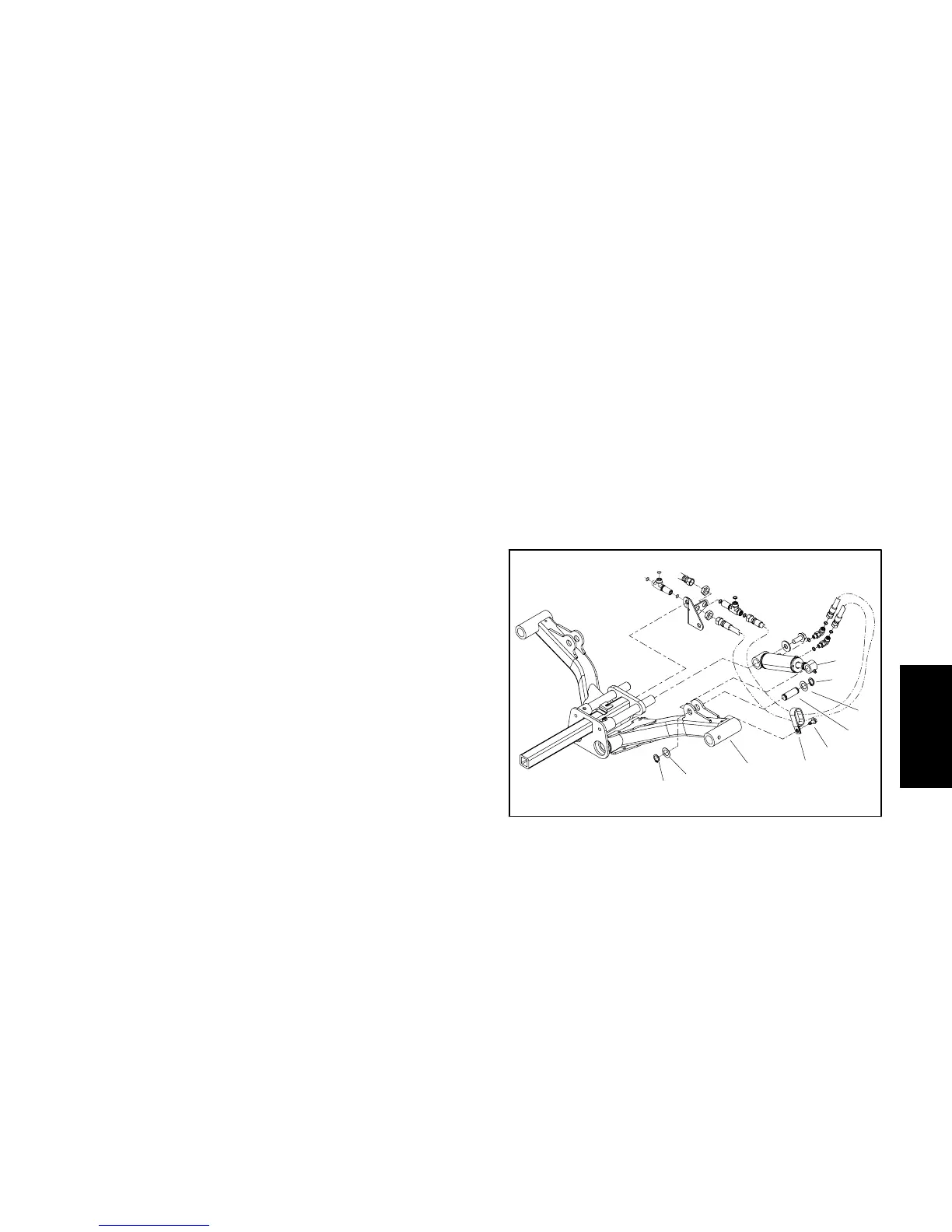

Installation (Fig. 22)

1. If lift arm pivot shaft (item 9) was removed from

frame, apply antiseize lubricant to pivot shaft surface

andinsertshaftintoframe.Alignholesinframeandpivot

shaft. Secure pivot shaft with new roll pin (item 13).

2. If pivot shaft (item 11) was removed from lift arm, in-

sert pivot shaft into lift arm and secure with cap screw

(item 14).

3. Slide rear lift arm onto pivot shaft.

4. Secure rear lift arm to machine:

A. ApplyPermatexBlueGelThreadlocker(orequiv-

alent) to threads of screws (items 4, 6 and 8).

B. Position bridge plate and bulkhead bracket with

attachedhydraulichosestoliftarmandframebrack-

et.

C. Install screws, flat washers (items 5 and 10) and

flangenut (item7)to bridgeplate,bulkheadbracket,

pivot shafts and frame bracket.

D. Torque 1/2” fasteners (items 4 and 8) from 75 to

95ft--lb(102to 128 N--m).Then,torque5/8”fasten-

ers(item 6)from135 to165 ft--lb (183to223 N--m).

5. Connect lift cylinder to lift arm (Fig. 21):

A. Align lift cylinder rod end to lift arm mounting

holes.

B. Slide cylinder pin with retaining ring and thrust

washer through the lift cylinder and lift arm.

C. Install second thrust washer on pin and secure

with second retaining r ing.

D. Position r--clamp and hydraulic hoses to lift arm.

Secure r--clamp with screw.

6. Mountcutting decktoliftarm (seeCutting DeckCar-

rier Frame Installation in the Service and Repairs sec-

tion of Chapter 7 -- Cutting Decks).

7. Lubricate lift arm and lift cylinder grease fittings.

1. Lift arm (#2 shown)

2. Lift cylinder

3. Retaining ring

4. Thrust washer

5. Cylinder pin

6. R--clamp

7. Screw

Figure 23

7

3

1

2

5

6

4

3

4

Chassis

Loading...

Loading...