Groundsmaster 4300--D Hydraulic SystemPage 4 -- 45

3. Read Precautions For Hydraulic Testing in this sec-

tion.

CAUTION

Beforeopeninghydraulicsystem,operateallhy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

RelievingHydraulicSystemPressurein theGen-

eral Information section of this chapter.

4. Raise and support operator seat to allow access to

hydraulic deck control manifold.

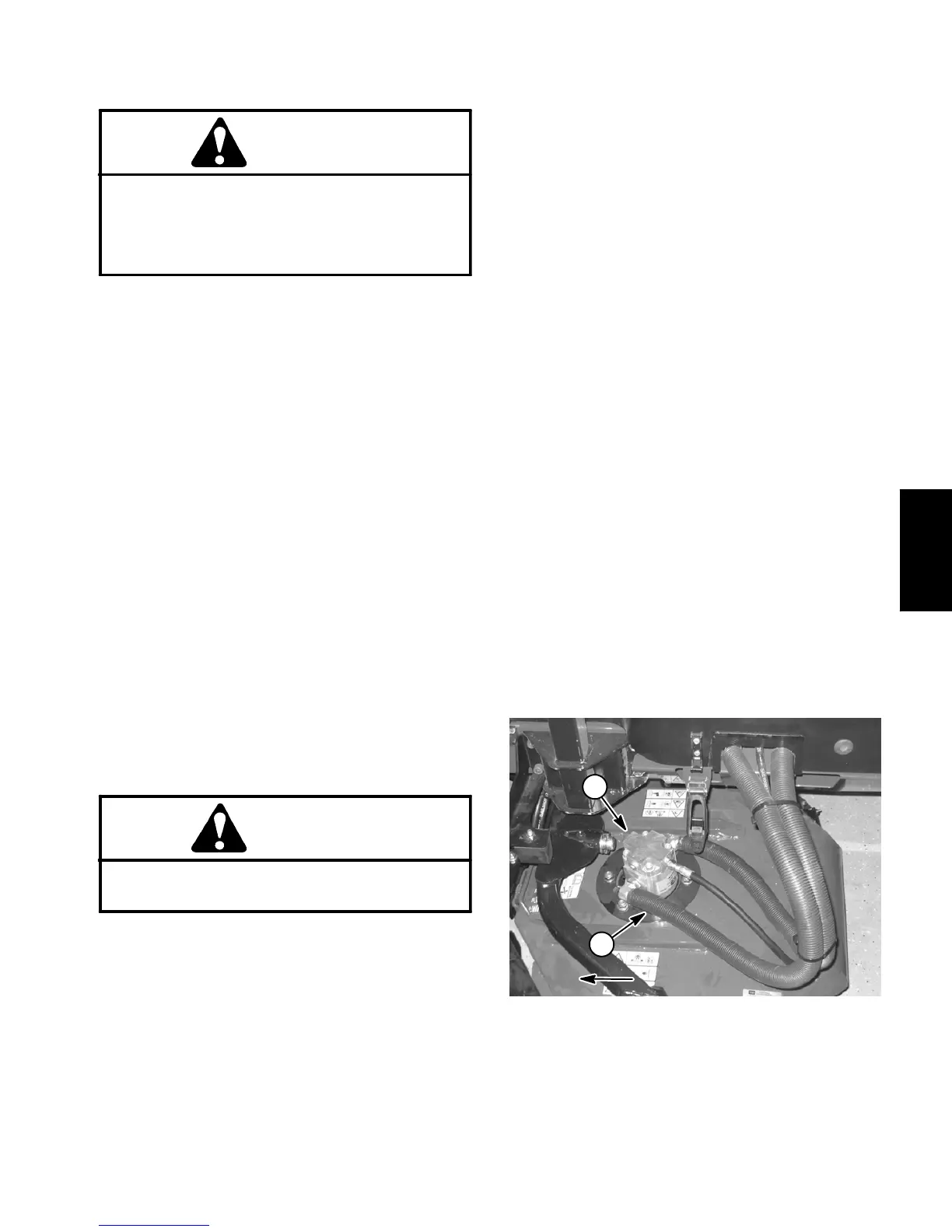

5. Thoroughlycleanjunctionofhydraulicinlethoseand

deck motor fitting on left side cutting deck for the relief

valvetobetested. Disconnecthose fromdeck motorfit-

ting (Fig. 46):

#2 cutting deck (left rear) for relief valve (PRV1)

#4 cutting deck (left front) for relief valve (PRV2)

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow meter is showing that the oil will

flowfromthedisconnectedhose,throughthetester

and into the deck motor.

6. Install tester with pressure gauge and flow meter in

series with the disconnected hose and hydraulic fitting

on deck motor. Make sure the flow control valve on

tester is fully open.

7. After installing tester, start engine and run at idle

speed. Check for any hydraulic leakage from test con-

nections and correct before proceeding with test.

8. Move throttle to full speed (3200 RPM) .

CAUTION

Keepawayfrom cutting decks during testtopre-

vent personal injury from rotating blades.

9. Have a second person occupy seat, press PTO

switchtoONandthenmovejoystickleverforwardtoen-

gage cutting decks.

IMPORTANT: When performing this test, do not

hold over reliefany longer thannecessary toobtain

pressure reading.

10.Watchpressure gaugecarefullywhileslowlyclosing

the tester flow control valve. As the relief valve lifts, the

pressure gauge needle w ill momentarily stop.

NOTE: Oncethe reliefvalvehasopened, systempres-

sure may continue to increase.

11.As the relief valve lifts, system pressure should be:

Approximately 2500 PSI (175 bar) for relief valve

(PRV1)

Approximately 3500 PSI (241 bar) for relief valve

(PRV2)

12.Openthetesterflowcontrolvalve,disengagecutting

decks and stop the engine.

13.If pressure is incorrect, remove PRV valve on mow

manifold and clean or replace valve (see Deck Control

Manifold Service in the Service and Repairs section of

this chapter).Also,if pressureis stilllow afterv alve ser-

vice, check for restriction in pump intake line. Gear

pump (P2) (front cutting deck circuit) and/or pump (P1)

(rear cutting deck circuit) could also be suspected of

wear, damage orinefficiency (see GearPump (P1) and

(P2) Flow Test in this section).

14.After testing is completed, make sure that engine is

stopped, then relieve hydraulic system pressure (see

RelievingHydraulic SystemPressure intheGeneralIn-

formation section of this chapter). Remove tester from

machine and connect hydraulic hose to deck motor fit-

ting.

15.Lower and secure operator seat.

1. Cutting deck motor (#2 shown)

2. Deck motor inlet hose

Figure 46

1

2

FRONT OF MACHINE

Hydraulic

System

Loading...

Loading...