Groundsmaster 4300--D Hydraulic SystemPage 4 -- 51

5. Thoroughly cleantest port(G4)on bottomoflift con-

trol manifold. C onnect a 5000 PSI (350 bar) pressure

gauge to test port.

6. After installing pressure gauge to manifold test port,

startengineandrunatidlespeed.Checkforanyhydrau-

licleakagefromtestconnectionsandcorrectbeforepro-

ceeding with test.

7. Move throttle to full speed (3200 RPM) .

IMPORTANT: Do not allow pressure to exceed 2500

PSI (172 bar).

IMPORTANT: While performing this test, hold joys-

tick lever in the raise position only long enough to

get a system pressure reading. Holding the lever in

raise for an extended period may damage system

components.

8. MakesurethatPTOswitchisOFFandthenpulljoys-

tickleverrearwardtopressurizeliftcircuit.Whileholding

lever in the raise (rearward) position, watch pressure

gauge carefully. As the cutting decks fully raise and the

lift relief valve lifts, system pressure should be:

Approximately 2000 PSI (138 bar)

9. Return the joystick lever to the neutral position and

stop the engine.

10.If measured pressure is incorrect, remove pressure

reducingvalve(PRV)fromliftcontrolmanifoldandclean

orreplacevalve(seeLiftControlManifoldServiceinthe

Service and Repairs section of this chapter). Also, if lift

circuitpressureislow,checkforrestrictioningearpump

intake line. Internal lift cylinder leakage would also

cause low lift circuit pressure (see Lift Cylinder Internal

LeakageTestinthissection).Gearpump(P4)couldalso

besuspectedofwear,damageorinefficiency(seeGear

Pump (P4) Flow Test in this section).

11.After testing is completed, make sure that engine is

stopped, then relieve hydraulic system pressure (see

RelievingHydraulic SystemPressure intheGeneralIn-

formation section of this chapter). Disconnect pressure

gauge from lift control manifold test port.

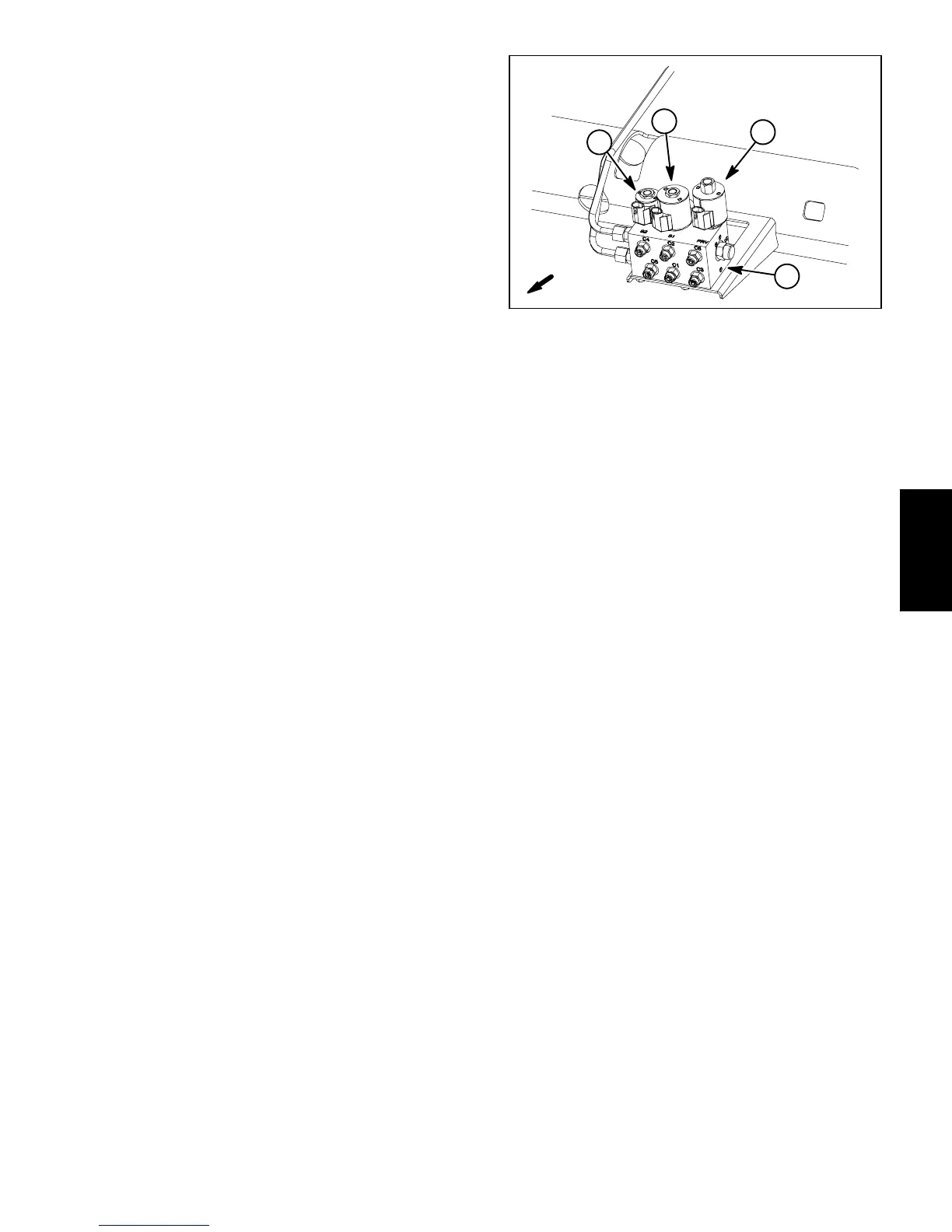

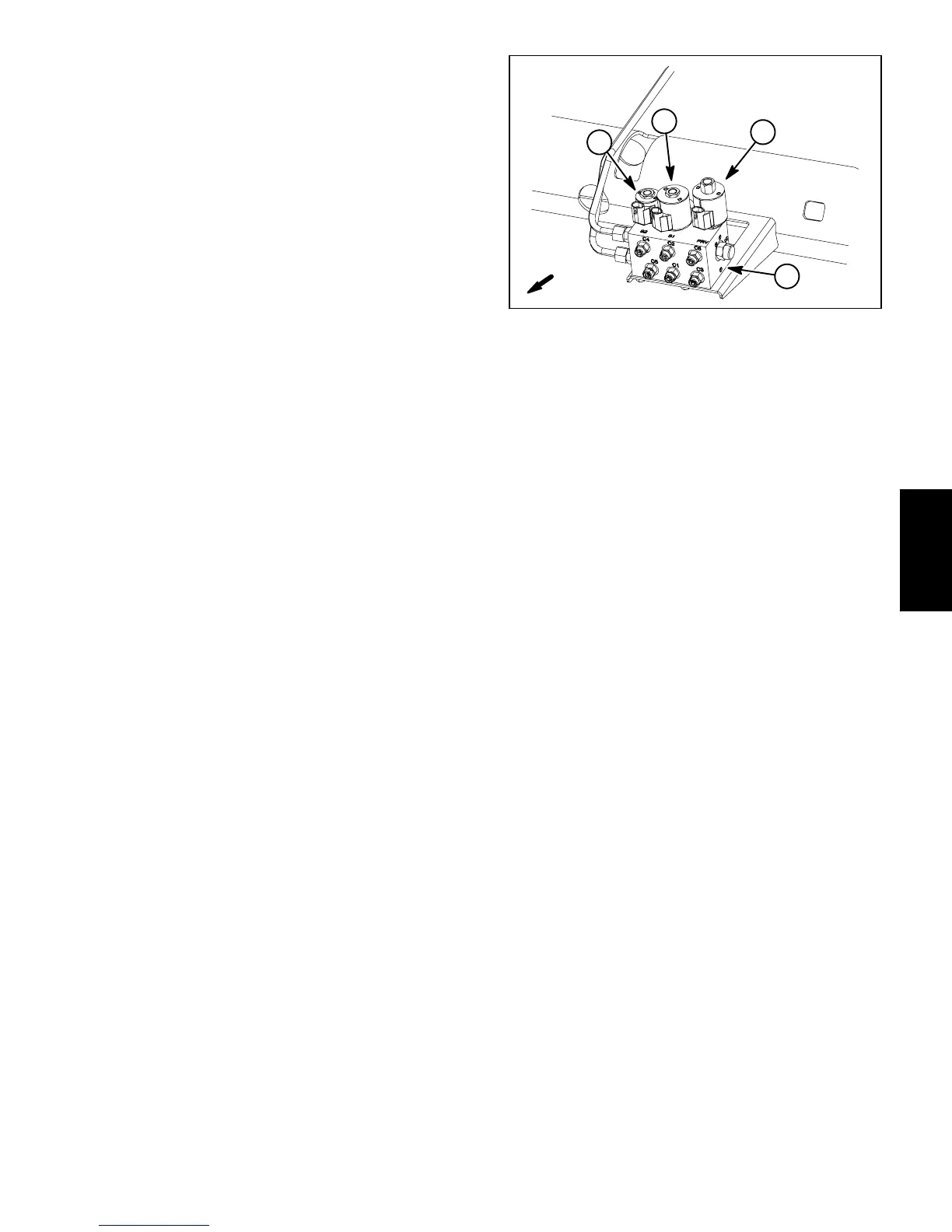

1. Lift control manifold

2. SV1 solenoid

3. SV2 solenoid

4. PRV solenoid

Figure 52

4

1

3

2

FRONT

Hydraulic

System

Loading...

Loading...