Groundsmaster 4300--D Hydraulic SystemPage 4 -- 67

Removal (Fig. 65)

1. Parkthemachineonalevelsurface,engageparking

brake, lower cutting decks and stop engine. Remove

key from the ignition switch.

2. Remove two(2) flangeheadscrews andflange nuts

that secure drive shaft guard hoop (item 4) to machine

frame. Remove guard.

3. Remove two(2) capscrews (item5) andflange nuts

(item9)thatsecuredriveshaftyoketopistonpumpinput

shaft.

4. Removesix(6)capscrews(item7)thatsecuredrive

shaft flange to engine flywheel.

5. Remove drive shaft assembly from machine.

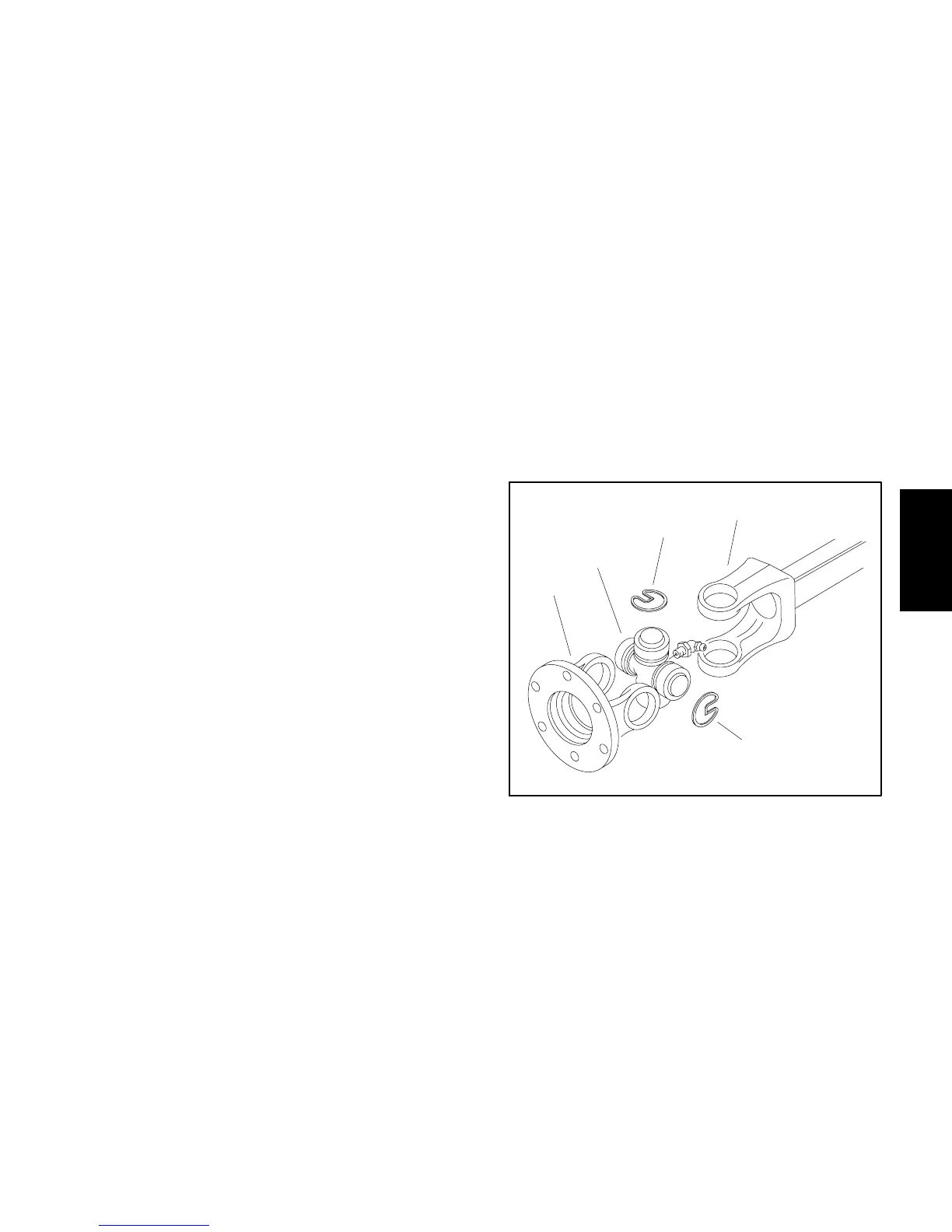

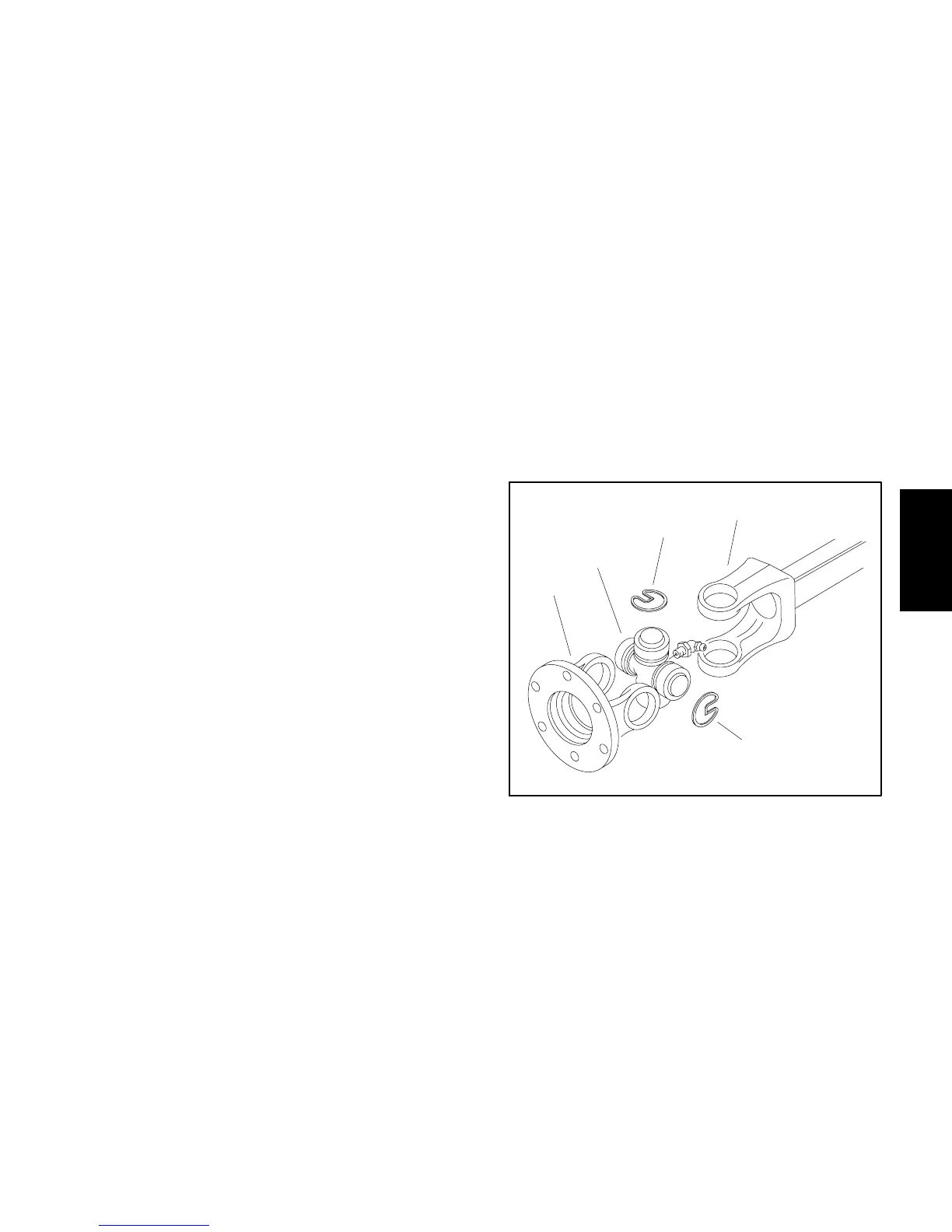

Drive Shaft Cross and Bearing Service (Fig. 66)

1. Remove snap rings that secure bearings in yokes.

IMPORTANT: Yokes must be supported when re-

moving and installing bearings to prevent damage.

2. Use a press to remove cross and bearings from

yokes. Thoroughly clean drive shaft yokes.

3. To install new cross and bearings:

A. Apply acoatingofgrease tobearingboresin end

yoke and shaft yoke.

B. Press one bearing partially into yoke.

C. Insert cross into yoke and bearing.

D. Holdcrossinalignmentandpressbearinginuntil

it hits the yoke.

E. Install snap ring into yoke groove to secure

installed bearing.

F. Place second bearing into yoke bore and onto

crossshaft.Press bearingintoyoke andsecurewith

snap ring.

G. Repeat procedure for other yoke.

H. Greasecrossuntilgreasecomesoutofallfour(4)

cups.

4. Make surethatassembled jointmoves withoutbind-

ing. Slight binding can usually be eliminated by lightly

rapping the yokelugs with a soft facedhammer. If bind-

ing continues, disassemble joint to identify source of

binding.

Installation (Fig. 65)

1. Applyantiseizelubricanttotractionpumpinputshaft.

2. Positiondriveshaftassemblytoengineandpumpin-

put shaft.

3. Apply Permatex Blue Gel Threadlocker (or equiva-

lent) to threads of cap screws (item 7) that secure drive

shaft flange to engine flywheel. Secure drive shaft

flange to flywheel with six (6) cap screws (item 7).

Torque cap screws from 34 to 42 ft--lb (46 to 56 N--m).

4. Slide driveshaftyokeon pumpinputshaftso yokeis

flush with end of input shaft. Secure drive shaft yoke to

pump input shaft with two (2) cap screws (item 5) and

flange nuts (item 9).

5. Position drive shaft guard hoop to machine frame

and secure with two ( 2) flange head screws and flange

nuts.

6. Lubricate grease fittings on drive shaft.

1. End yoke

2. Cross and bearing kit

3. Snap ring (4 used)

4. Shaft yoke

Figure 66

1

2

3

4

3

Hydraulic

System

Loading...

Loading...