Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

MaintenanceSafety

•Beforecleaning,servicing,oradjustingthe

machine,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutofftheengine,removethekey,disconnect

thespark-plugwire,andwaitforallmoving

partstostop.

–Chockthewheels.

–Removethemachinefromthetractionunit.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededoryouneedassistance,contactan

authorizedT orodistributor.

•Supportthemachinewithblocksorjackstands

whenworkingbeneathit.

•Ensurethatallguardsareinstalledsecurelyafter

maintainingoradjustingthemachine.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Donotchargethebatterieswhileservicingthe

machine.

•Toreducethepotentialrehazard,keepthe

engineareafreeofexcessivegrease,grass,

leaves,andaccumulationofdirt.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Ifyoumustruntheenginetoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andallotherpartsofyourbodyaway

fromtheengineandanymovingparts.Keep

bystandersawayfromthemachine.

•Cleanupoilandfuelspills.

•Keepallpartsingoodworkingconditionandall

fastenerstightened.Replacealldamagedor

missingdecals.

•Donotinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Donotoverspeedtheenginebychangingthe

governorsettings.Toensuresafetyandaccuracy,

haveanauthorizedT orodistributortocheckthe

maximumenginespeedwithatachometer.

•Ifmajorrepairsareevernecessaryorassistance

isrequired,contactanauthorizedT orodistributor.

•Alteringthismachineinanymannermayaffectthe

operationofthemachine,performance,durability,

oritsusemayresultininjuryordeath.Such

usecouldvoidtheproductwarrantyofTheT oro

Company.

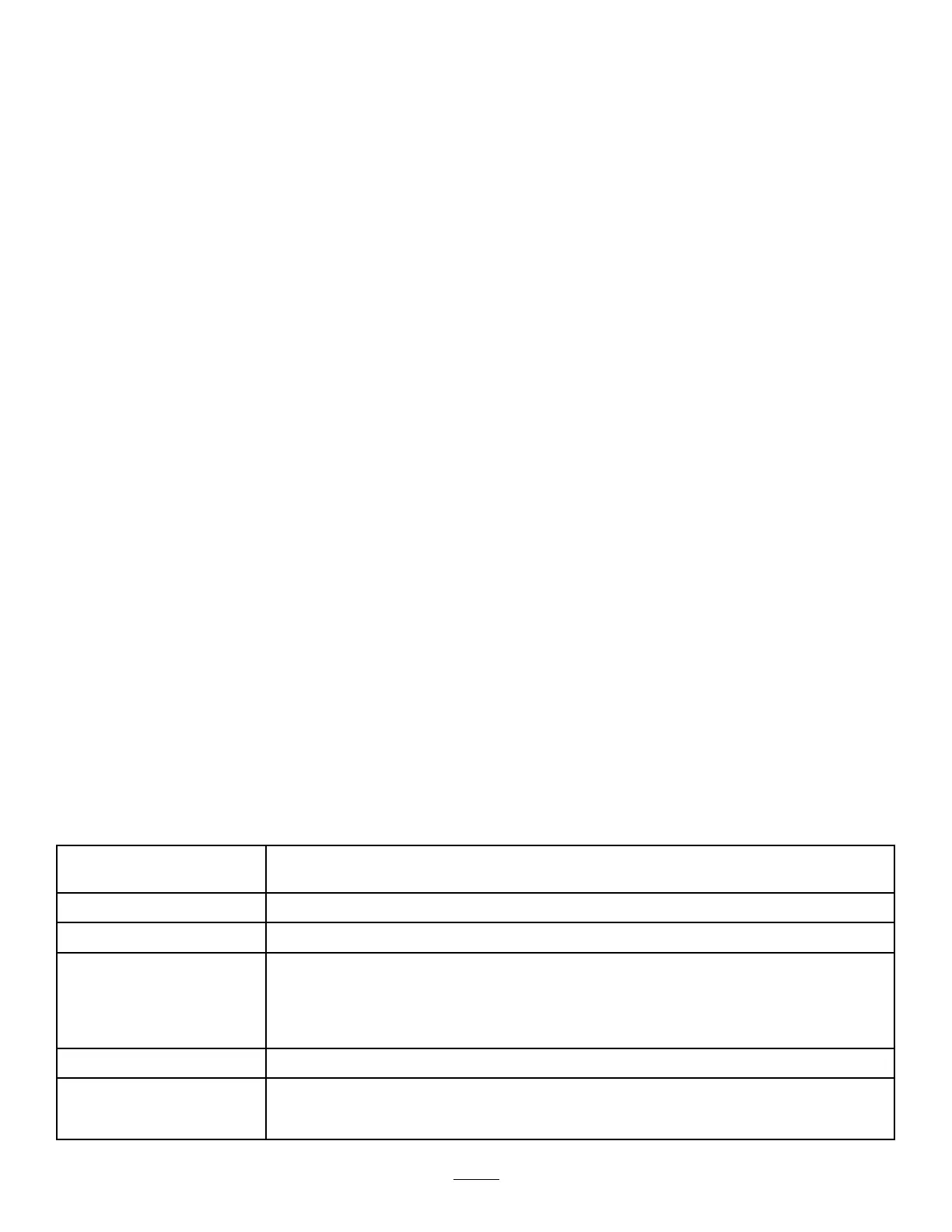

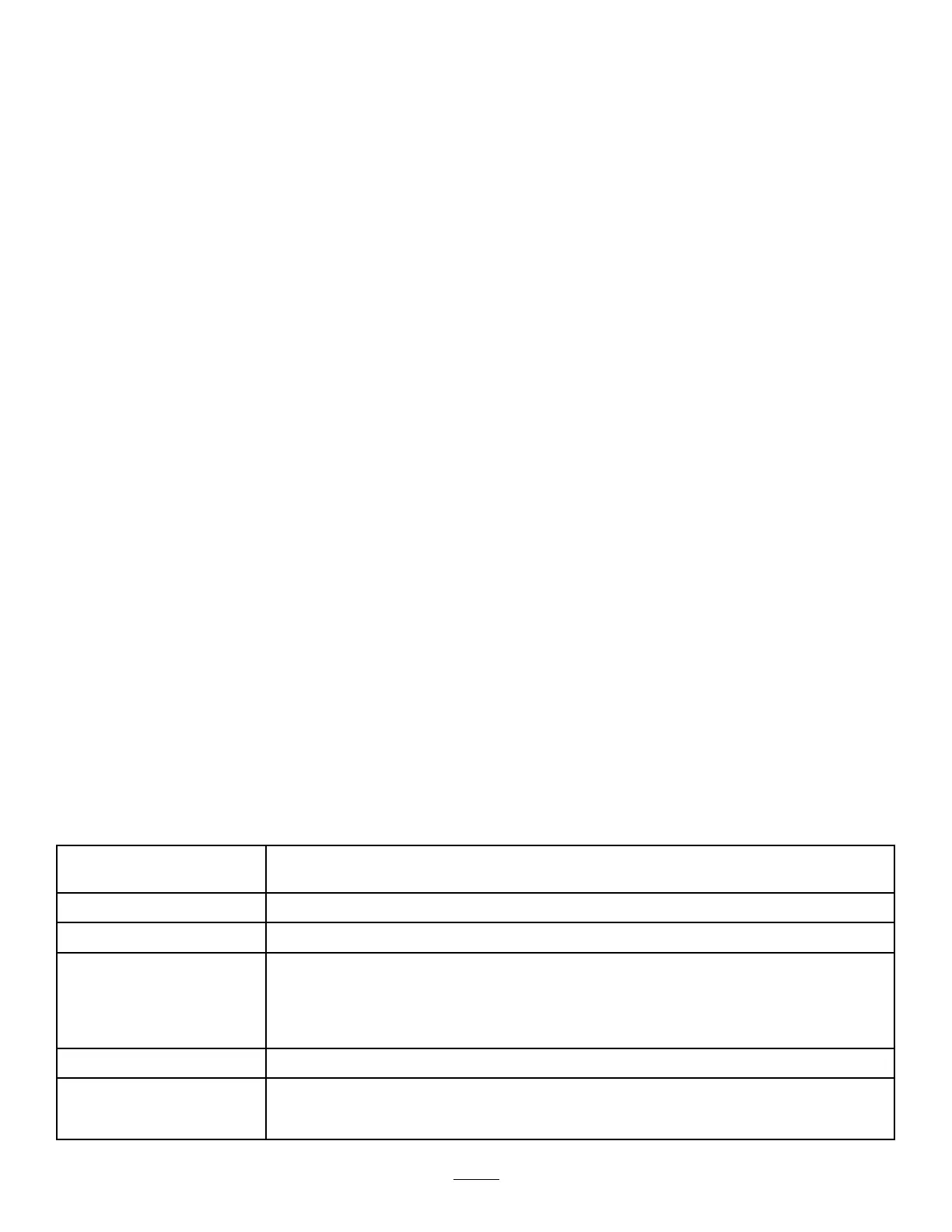

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Checktheconditionandthetensionofthebelt.

Aftertherst10hours

•Checkthetorqueofthewheellugnuts.

Beforeeachuseordaily

•Checktheengine-oillevel.

•Cleantheenginescreenandtheoilcooler.

•Checkthetireairpressure.

•Checktheblowernozzleclamp.

•Cleanthenozzleguides.

Every50hours

•Checktheconditionandthetensionofthebelt.

Every100hours

•Replacetheairlterelement(morefrequentlyifconditionsaredustyorsandy).

•Changetheengineoil.

•Checktheconditionofthetires.

22

Loading...

Loading...