BeltMaintenance

Adjustingthe

Nozzle-ControlBeltTension

ServiceInterval:Aftertherst8hours

Every50hours

Ifthenozzle-controlbeltslipswhilechanging

blower-nozzledirection,adjustthebelttension.

1.Preparethemachineformaintenance;referto

PreparingforMaintenance(page24).

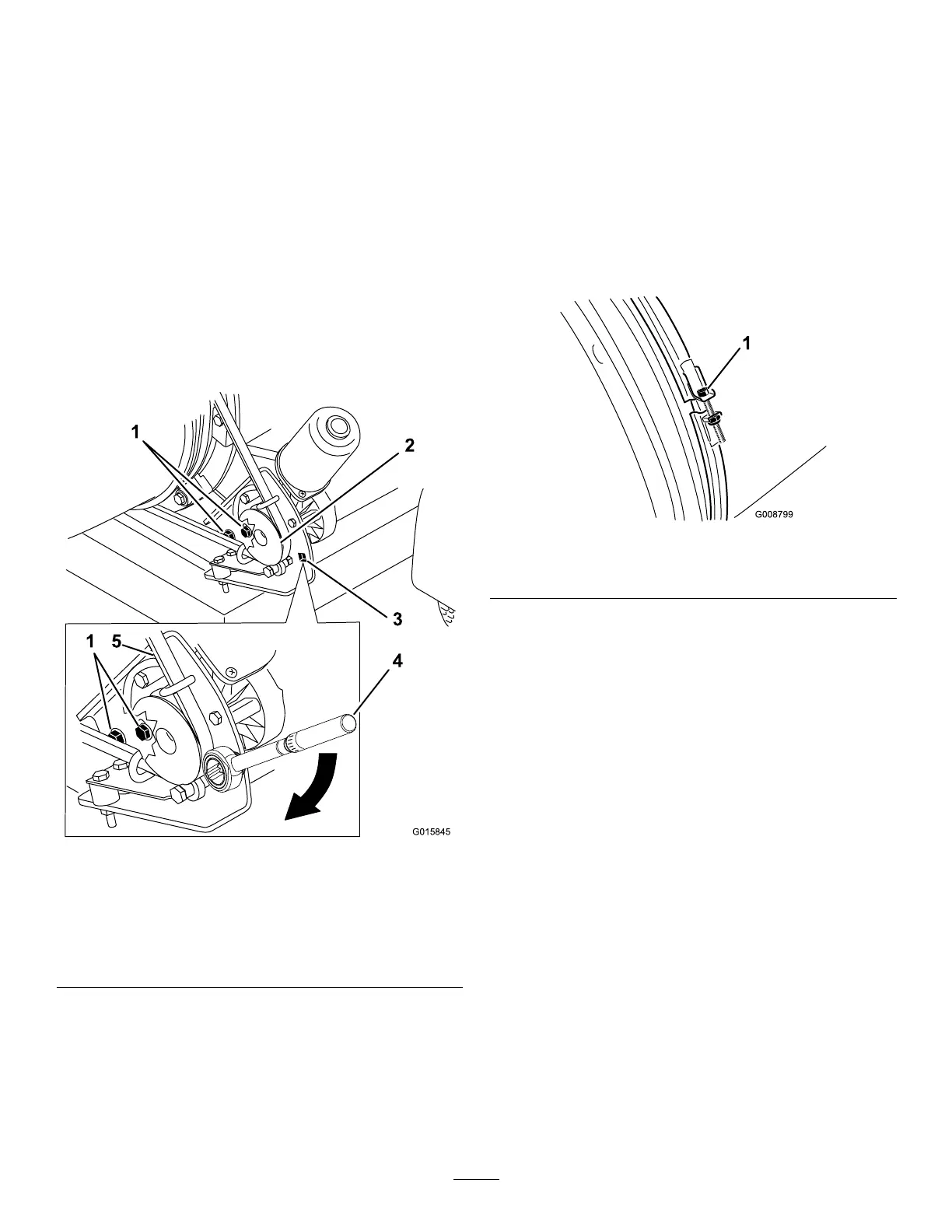

2.Loosenthe2angecapscrewsand2ange

locknutssecuringthemotor-mountingbracketto

thehousingmountofthemachineframe(Figure

36).

g015845

Figure36

1.Mountingbolts4.Torquewrenchinpulley

mountingbracket—22.6to

26.0N∙m(200to230in-lb)

2.Pulley5.Belt

3.Holefortorquewrench

3.Insertthedriveofatorquewrenchintothepulley

mountingbracketasshowninFigure36.

4.Pivotthemotor-mountingbracketawayfromthe

blowernozzle(Figure36)untilthetorquewrench

reads22.6to26.0N∙m(200to230in-lb).

5.Whileholdingbelttension,tightenthe2ange

capscrewsand2angelocknuts.

BlowerMaintenance

Checkingthe

Blower-NozzleClamp

ServiceInterval:Beforeeachuseordaily

1.Preparethemachineformaintenance;referto

PreparingforMaintenance(page24).

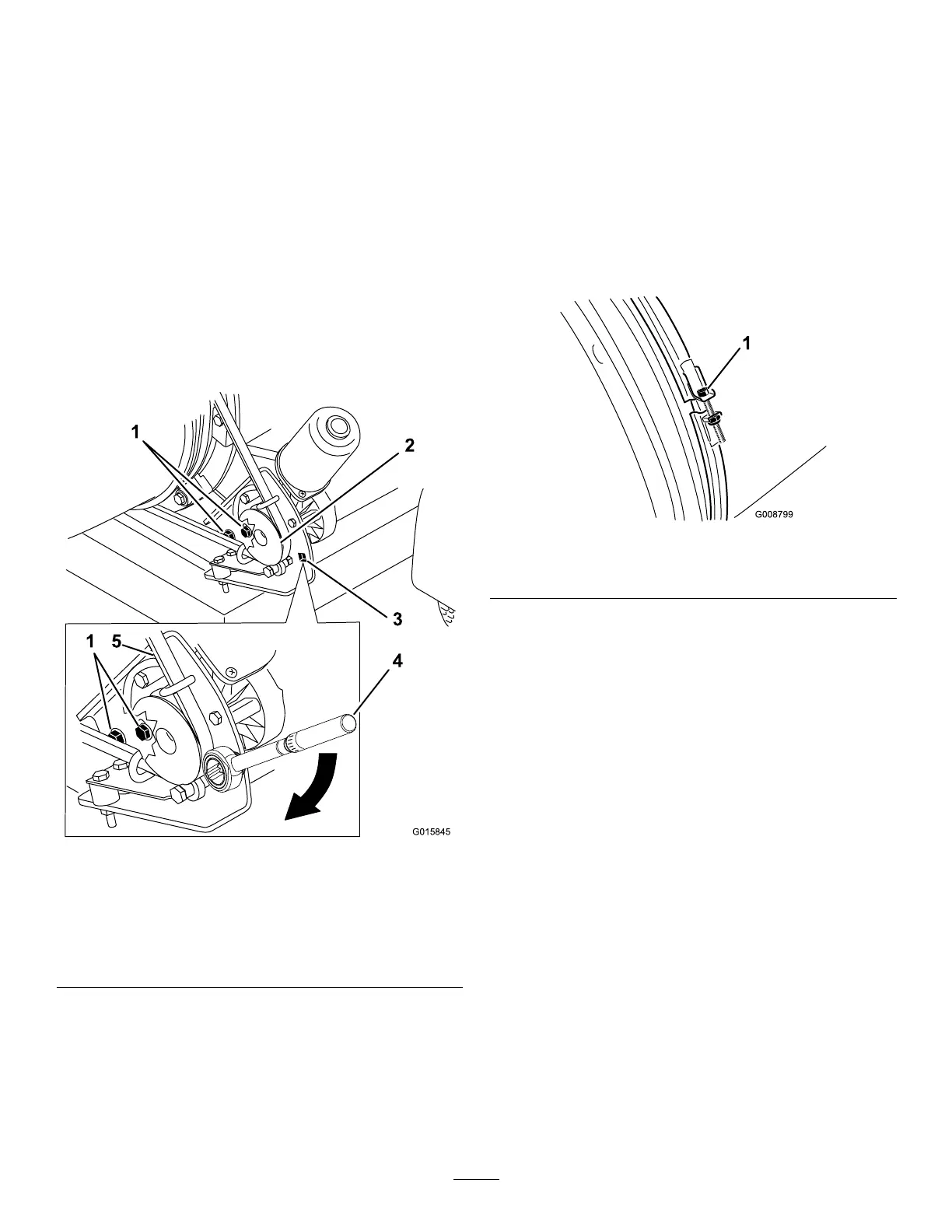

2.Checktheblower-nozzleclampforsignsofwear

ordamage(Figure37).

g008799

Figure37

1.Blower-nozzleclamp

3.Checktheblower-nozzleclampdailytoensure

thatitistight(Figure37).

Important:Iftheblowernozzlecontactsan

obstacleorthroughalowareaintheterrain,

theblower-nozzleclampcouldbecome

loose.

4.Iftheclampisloose,torquethenutoftheclamp

to5.1to5.7N∙m(45to50in-lb).

33

Loading...

Loading...