PreparingtheMachinefor

WeldRepairs

Important:Failuretodisconnectthebattery

maypermanentlydamagetothewireless-control

moduleandtheTECcontroller.

•Disconnectthenegative-batterycablefromthe

batterybeforeweldingonthemachine.

•Connectthenegative-batterycabletothebattery

afteryounishweldingonthemachine.

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

ServicingtheAirCleaner

ServiceInterval:Every100hours—Replacetheair

lterelement(morefrequentlyif

conditionsaredustyorsandy).

CheckingtheAirFilter

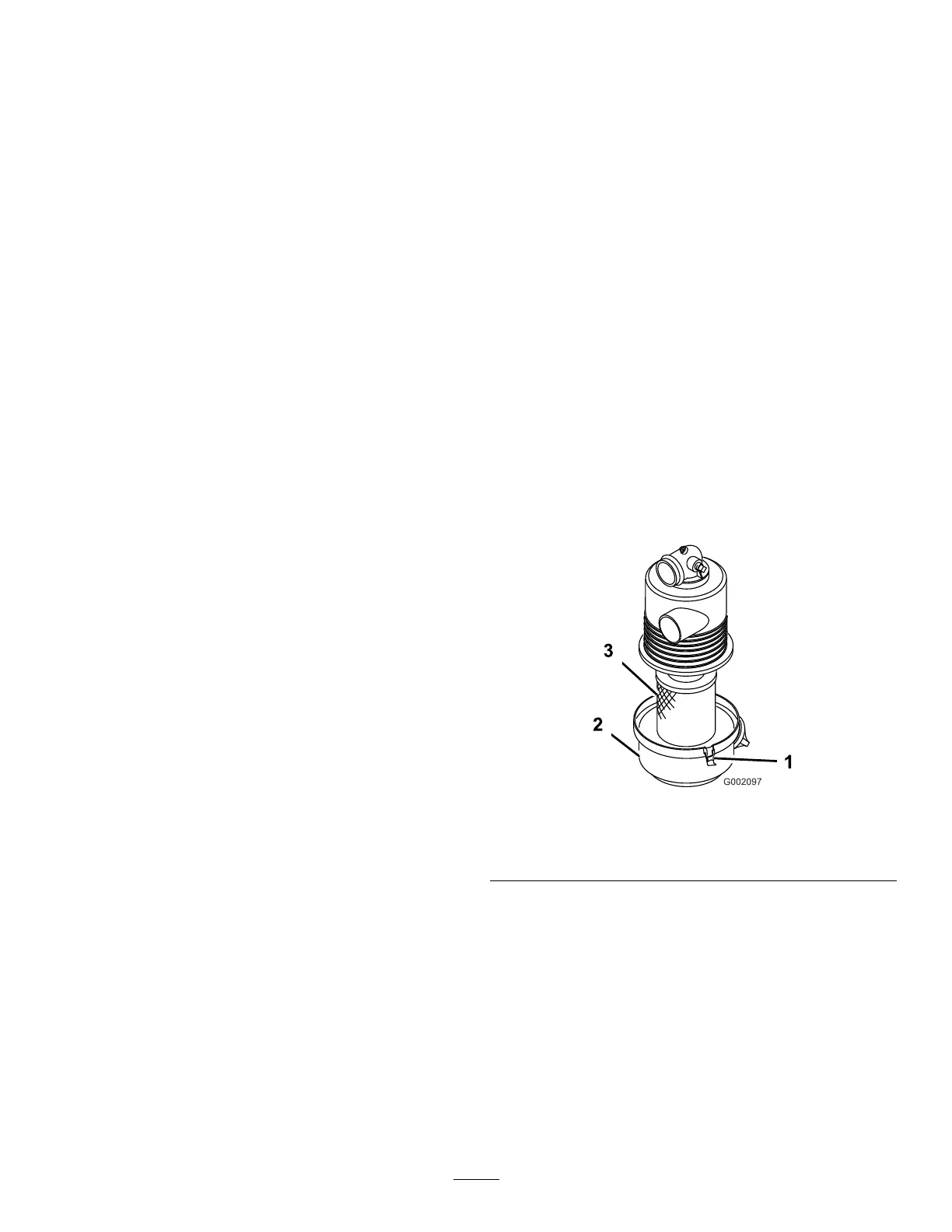

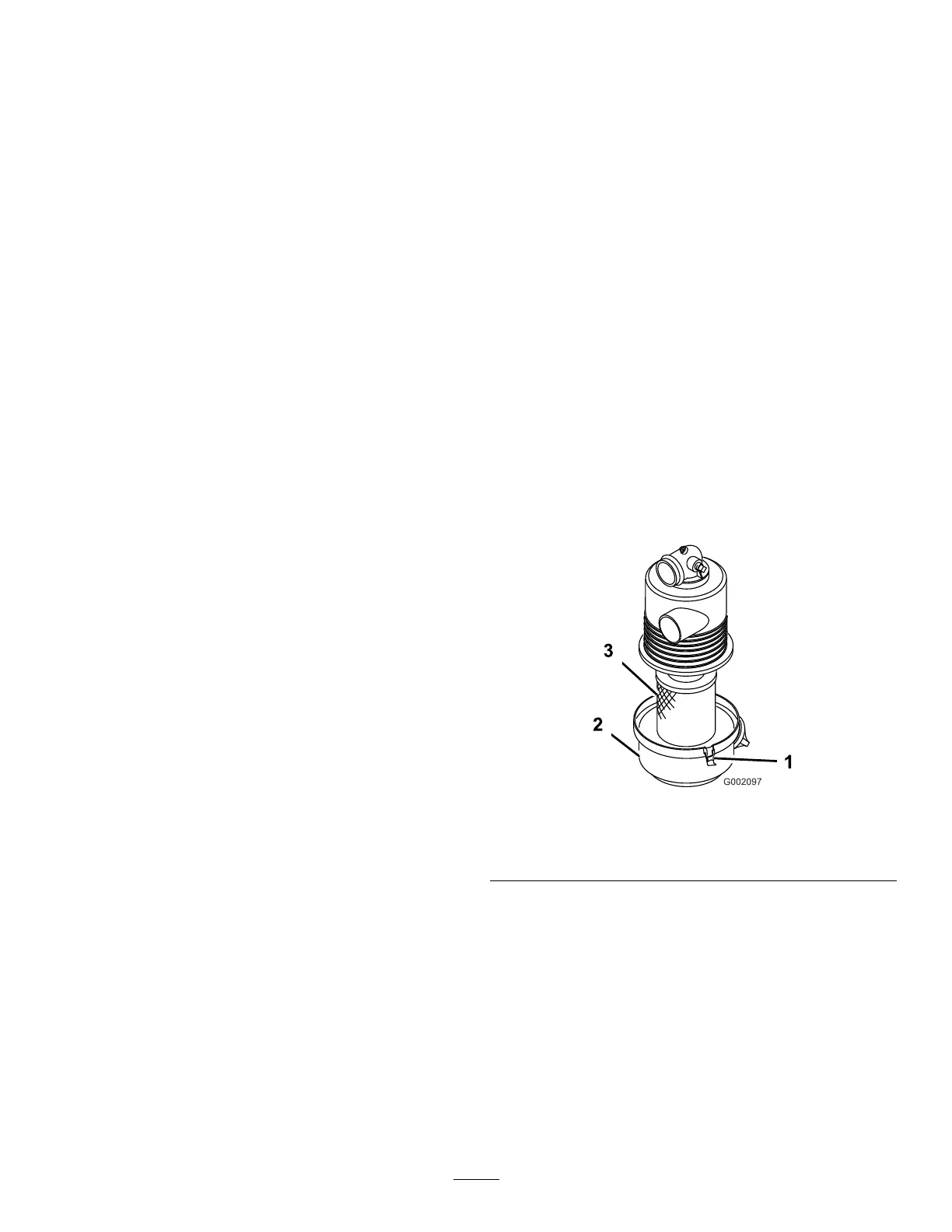

1.Checktheaircleanerbodyfordamage,which

couldpossiblycauseanairleak.Ensurethat

thecoversealsaroundtheair-cleanerbody

(Figure20).

Note:Replaceadamagedair-cleanercover

orhousing.

g002097

Figure20

1.Latch

3.Air-lterelement

2.Air-ltercover

2.Releasethelatchessecuringtheair-ltercover

totheair-lterhousing(Figure20).

3.Separatetheair-ltercoverfromtheair-lter

housing,andcleantheinsideofthecover

(Figure20).

4.Gentlyslidetheair-lterelementoutofthelter

housing.

Note:Toreducetheamountofdustdislodged,

avoidknockingthelteragainsttheair-lter

housing.

5.Inspecttheair-lterelement.

25

Loading...

Loading...