ServicingtheSparkPlugs

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplugs.

Useasparkplugwrenchforremovingandinstalling

thesparkplugsandagappingtool/feelergaugeto

checkandadjusttheairgap.Installnewsparksplugs

ifnecessary.

Type:Champion®RC12YC,Champion®Platinum

3071orequivalent

AirGap:0.76mm(0.030inch)

CheckingtheSparkPlugs

ServiceInterval:Every200hours

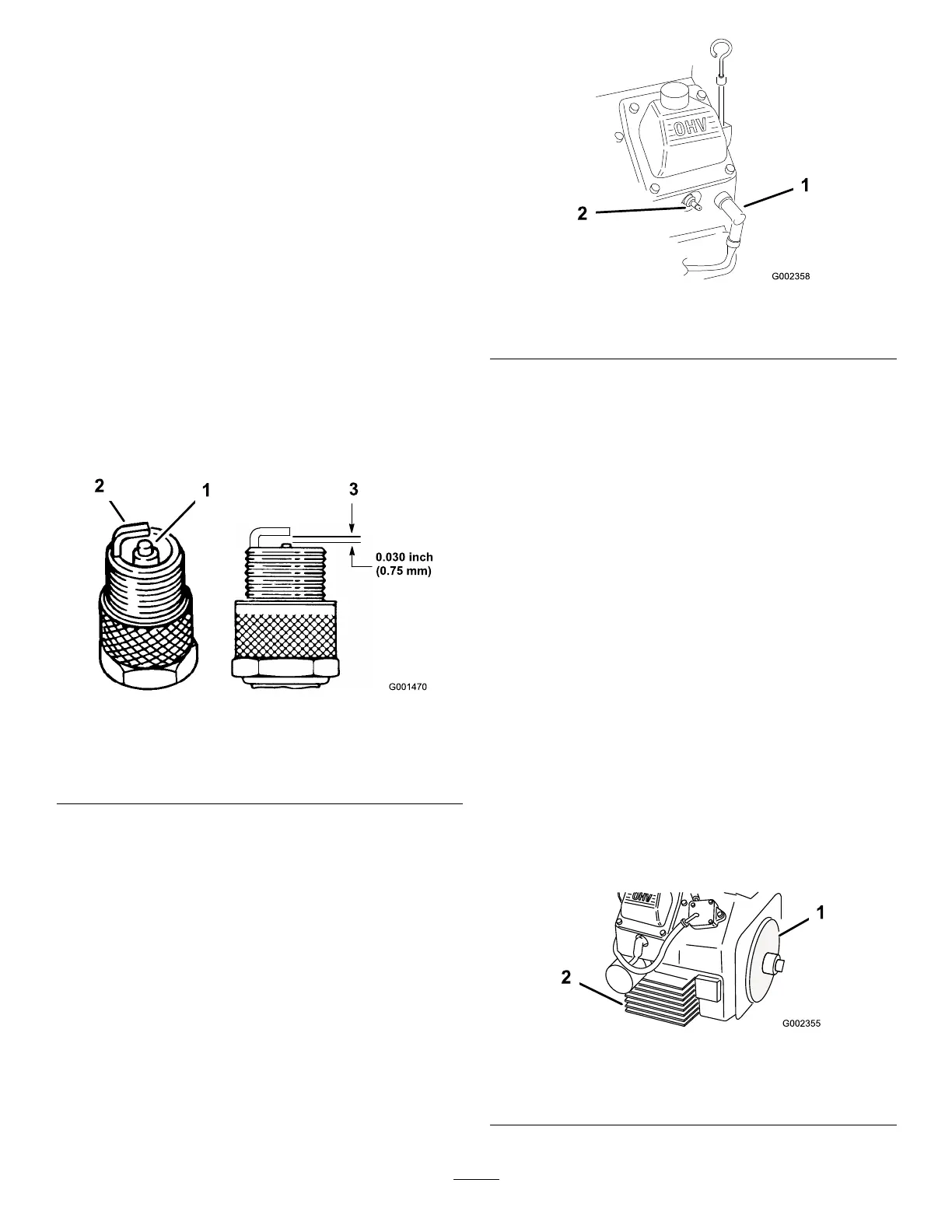

1.Lookatthecenterofthesparkplugs(Figure27).

Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoating

ontheinsulatorusuallymeansthattheair

cleanerisdirty.

g001470

Figure27

1.Centerelectrodeinsulator

3.Airgap—0.75mmor0.030

inch(nottoscale)

2.Sideelectrode

Important:Alwaysreplaceasparkplug

whenithasablackcoating,wornelectrodes,

anoilylm,orcracks.

2.Checkthegapbetweenthecenterandside

electrodes(Figure27).Bendthesideelectrode

ifthegapisnotcorrect.

RemovingtheSparkPlugs

1.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

2.Disconnectthespark-plugwiresfromthespark

plugs(Figure28).

g002358

Figure28

1.Spark-plugwire2.Sparkplug

3.Cleanaroundthesparkplugstopreventdirt

fromfallingintotheengineandpotentially

causingdamage.

4.Removethesparkplugsandthemetalwashers.

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.

Ensurethattheairgapissetcorrectly;referto

CheckingtheSparkPlugs(page29).

2.Tightenthesparkplugsto24to30N∙m(18to

22ft-lb).

3.Connectthespark-plugwirestothesparkplugs

(Figure28).

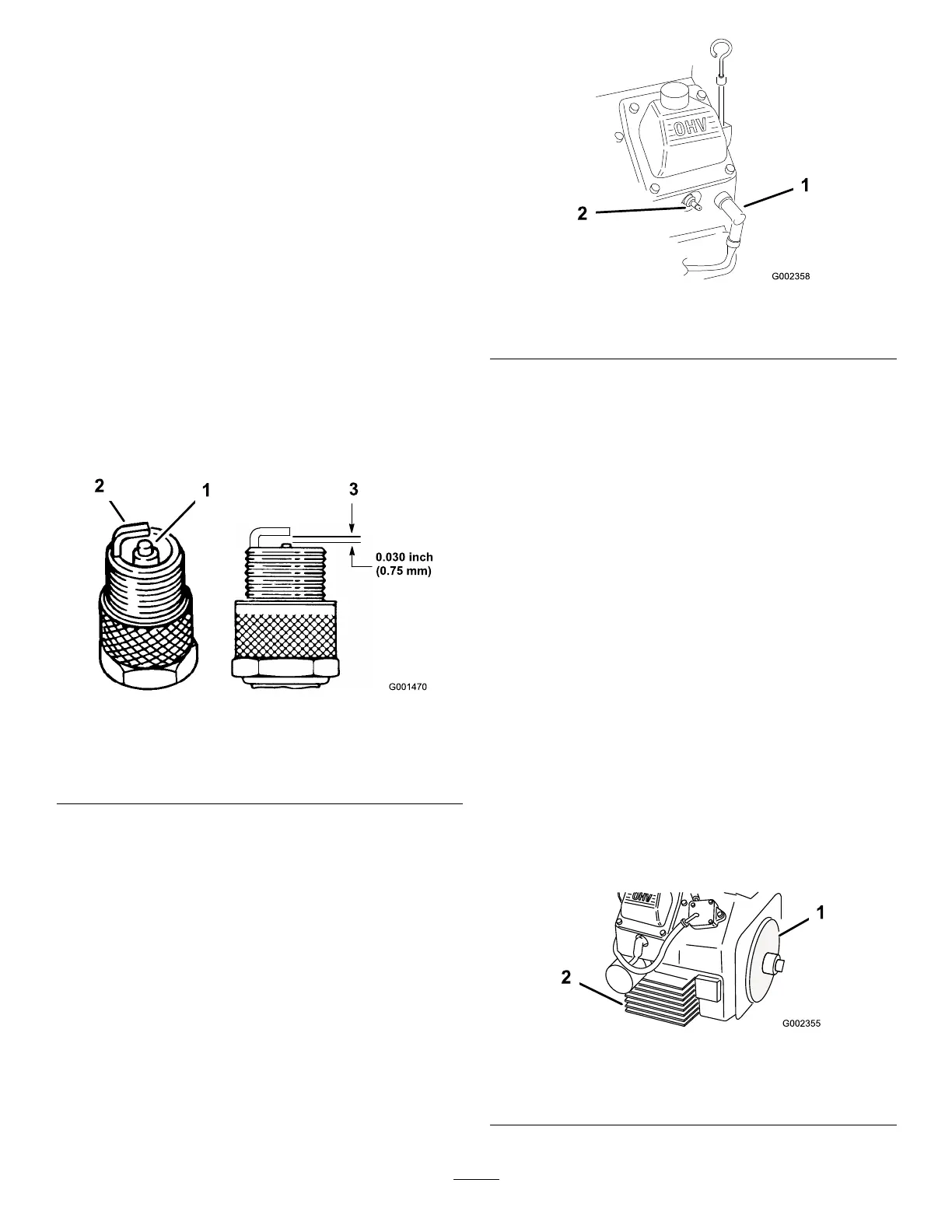

CleaningtheEngineScreen

andtheOilCooler

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,checkandcleantheenginescreen

andoilcooler.Removeanybuildupofgrass,dirtor

otherdebrisfromtheoilcoolerandenginescreen

(Figure29).

g002355

Figure29

1.Enginescreen

2.Oilcooler

29

Loading...

Loading...