whentousetheuppermountingholes,referto

10ConnectingthePTOShaft(page15).

SR54andSR54-SAeratorsonly

Note:Thefactoryinstallsthehitchpinsand

lynchpinsontotheSR54andSR54-Saerators

beforeshipping.

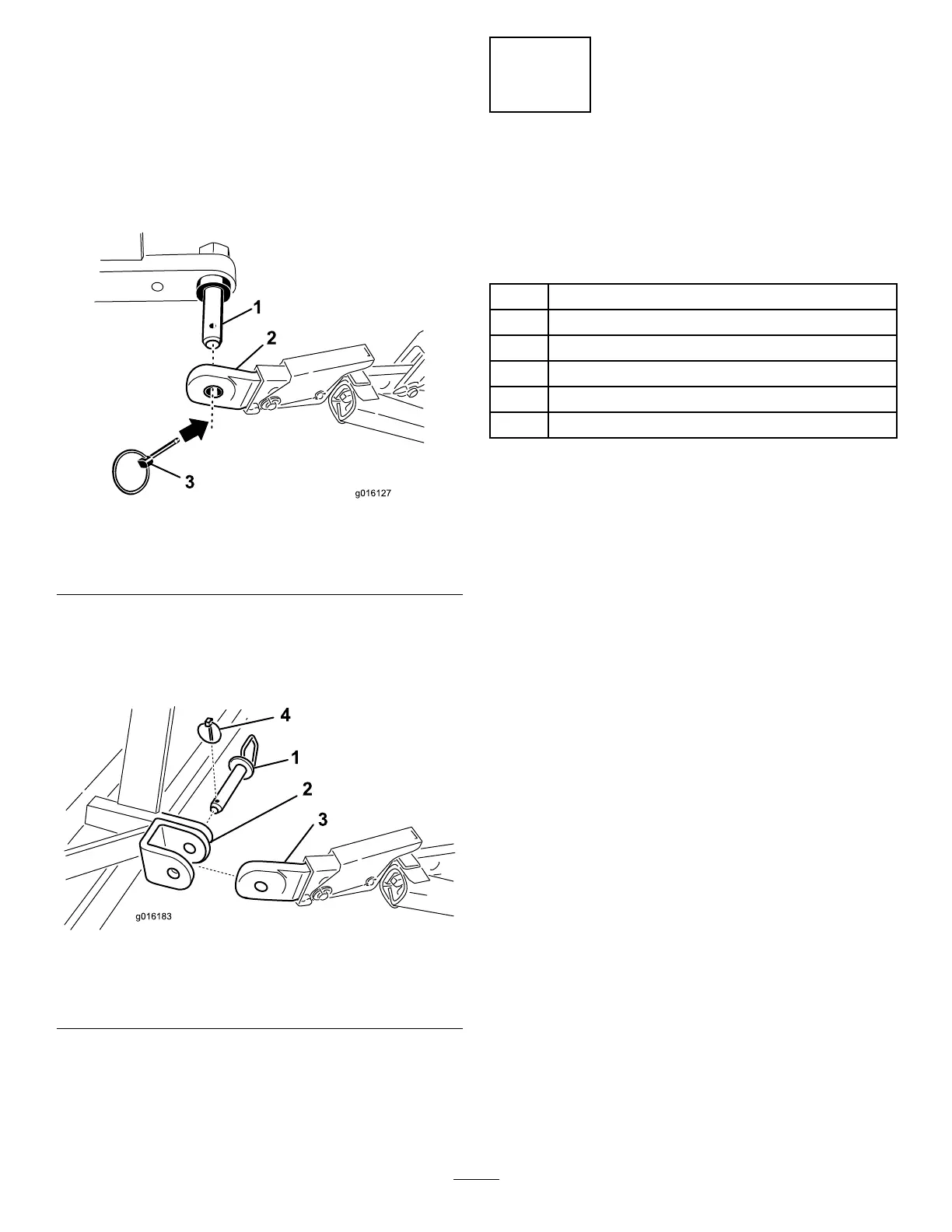

4.Securethelowerlinkarmstotheaerator

mountingpinswithlynchpins(Figure3).

g016127

Figure3

1.Aeratormountingpin3.Lynchpin

2.Lowerlink

SR70,SR70-S,andSR72Aeratorsonly

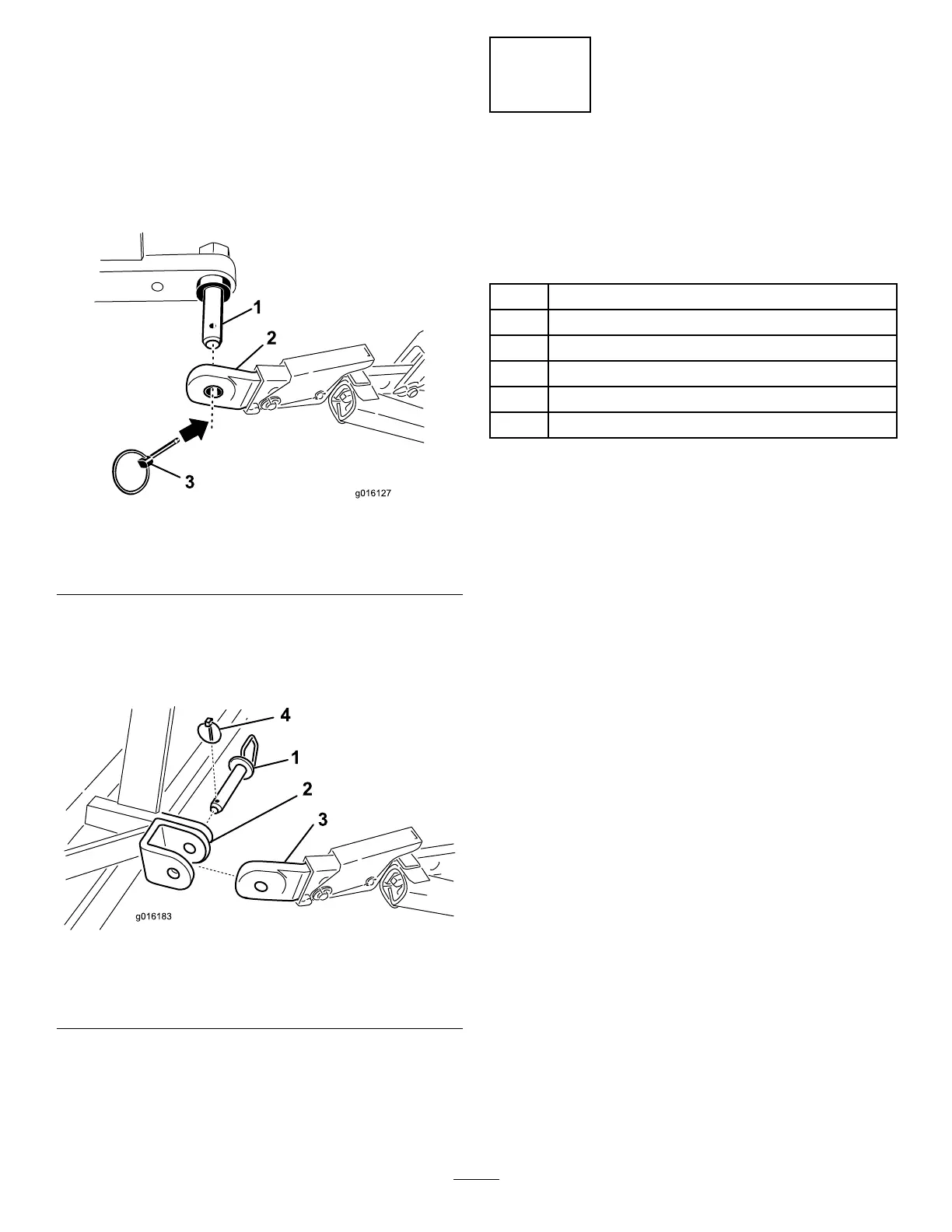

5.Securethelowerlinkarmstotheaerator

mountingbracketswithhitchpinsandlynchpins

(Figure4).

g016183

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket4.Lynchpin

3

ConnectingtheHydraulic

TopLink

ModelsSR54,SR70,andSR72

Partsneededforthisprocedure:

1Hydraulictoplink

1

Hydraulichose—106cm(3-1/2ft)

1

Hydraulichose—76cm(2-1/2ft)

2Extensionbracket

1Rotationalbracket

2Hosequickcouplings

Procedure

Note:Makesurethatthesuppliedcouplingsare

correctforthetractionunit.Ifnot,contactthetraction

unitmanufacturertoobtainthecorrectcouplings.

Yourtractionunitmusthaveadoubleacting

spoolvalvewithanoperatorcontrolleverand2

quick-releasecouplings12.7mm(1/2inch)atthe

rearofthetractionunit.Thefactoryprovides2quick

couplingstotontothehydraulictoplinkhoses

(1/2-14NPTFhoseendthreadsize).

Usetheprocedurethatfollowstoinstallthehoses

anddeterminetheneedfortheextensionorrotation

blocks.Thisinformationalsohelpsyoutodetermine

thedepthrangeoftheaerator.

1.Securetheconnectinglinkendofthehydraulic

toplinktothetractionunitwiththepinssupplied

withthetractionunit(Figure5).

Positionthehydraulictoplinksothattherod

endistowardtheaeratorandthecylinderports

aligntowardtheauxiliarypowerhydraulicsof

thetractionunit.

Note:Ifyoumustpositionthehydrauliccylinder

withtheportsfacingupward,usetherotational

blockinsteadofthestandardmountingblockto

repositionthecylinder(Figure5).Youmayuse

a90°hydraulicttinginsteadoftherotational

block(90°ttingsarenotincluded).

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglink

fromthecylinder.

9

Loading...

Loading...