LoaderMaintenance

TorquingtheLoaderArm

AdjustmentScrews

ServiceInterval:Every25hours

Checkthetorquewheneverthelowerloaderarms

rattle.

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Oneachloaderarm,loosenthesetscrewonthe

4adjustmentscrews.

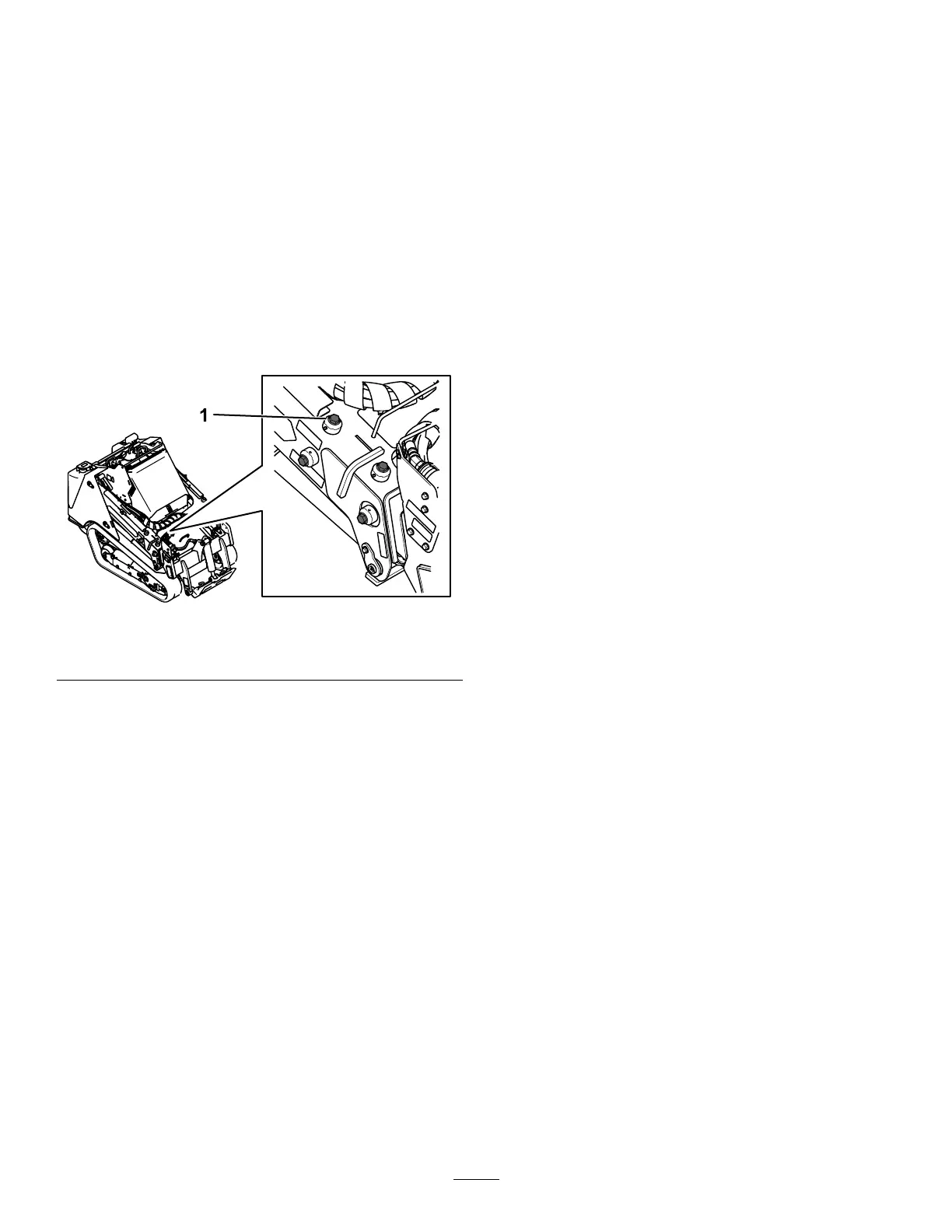

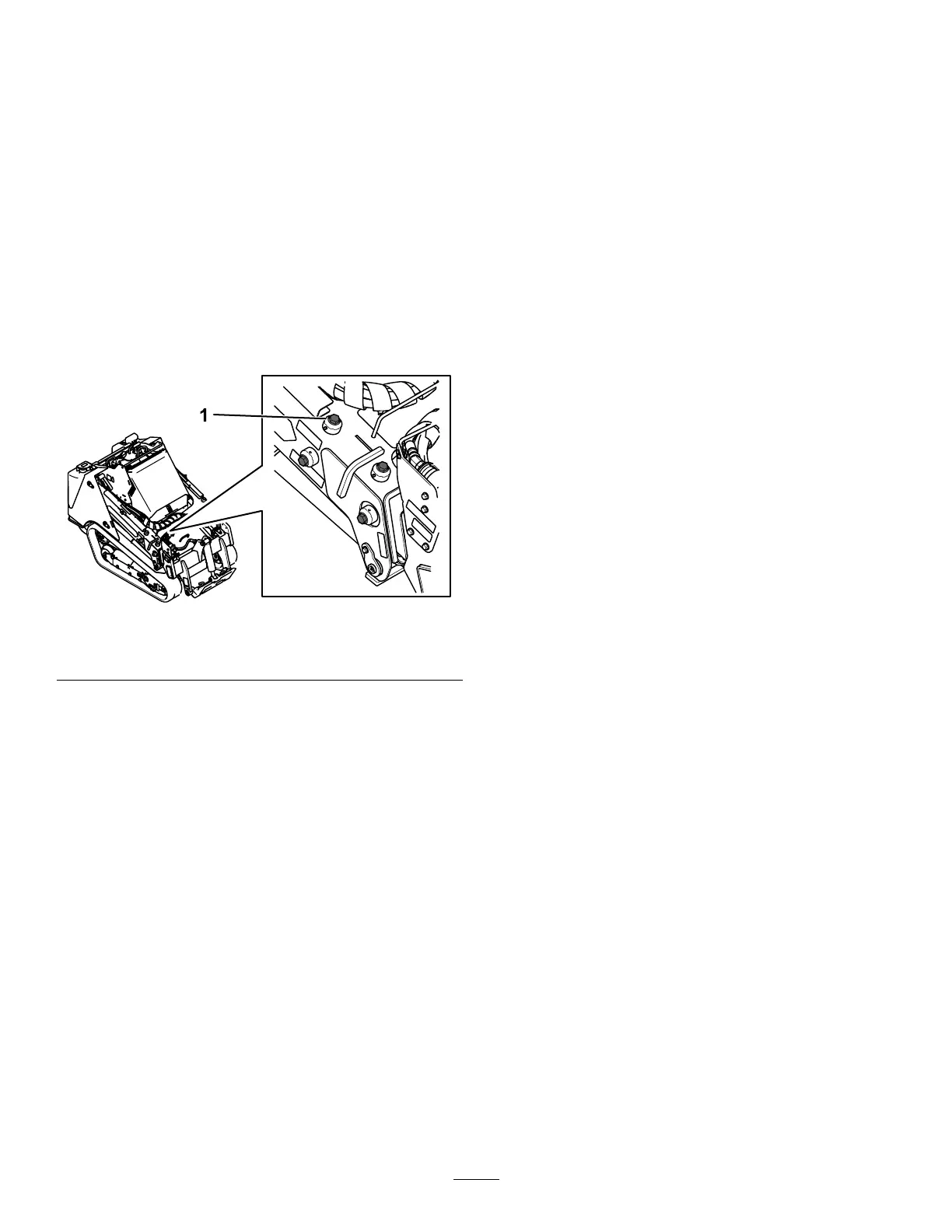

g362079

Figure103

1.Adjustmentscrew(4)

4.Torquetheadjustmentscrewsto27N∙m(20

ft-lb).

5.Checkthatthelengthoftheadjustmentscrews

thatisprotrudingfromthearmsisequalsideto

side.

6.Applymedium-strengththread-locking

compoundtothesetscrewsandtightenthem

untiltheyjustcontacttheadjustmentscrews.

Important:Donotovertightenthe

setscrews;otherwiseyoumaydamagethe

adjustmentscrewthreads.

Cleaning

RemovingDebris

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithblocked

screensand/orcoolingshroudsremovedwill

resultinenginedamagefromoverheating.

1.Parkthemachineonalevelsurfaceandlower

theloaderarms.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Openthehood.

4.Cleananydebrisfromthefrontandside

screens.

5.Wipeawaydebrisfromtheaircleaner.

6.Cleananydebrisbuildupontheengineandin

theoilcoolernswithabrushorblower.

Important:Operatingtheenginewith

blockedscreensand/orcoolingshrouds

removedwillresultinenginedamagedueto

overheating.

7.Cleandebrisfromthehoodopening,mufer,

heatshields,andradiatorscreen(ifapplicable).

8.Closethehood.

WashingtheMachine

Whenpressurewashingthemachine,dothefollowing:

•Wearappropriatepersonalprotectiveequipment

forthepressurewasher.

•Keepallguardsinplaceonthemachine.

•Avoidsprayingatelectroniccomponents.

•Avoidsprayingatedgesofdecals.

•Spraytheexteriorofthemachineonly.Donot

spraydirectlyintoopeningsinthemachine.

•Sprayonlythedirtypartsofthemachine.

•Usea40-degreeorlargerspraynozzle.40-degree

nozzlesareusuallywhite.

•Keepthetipofthepressurewasheratleast61cm

(2ft)awayfromthesurfacebeingwashed.

•Useonlypressurewasherswithpressurebelow

13790kpa(2000psi)andowbelow7.6L(2US

gallons)perminute.

•Replacedamagedorpeelingdecals.

•Greaseallgreasepointsafterwashing;referto

GreasingtheMachine(page45).

64

Loading...

Loading...