P9 ASD Installation and Operation Manual 175

Process Hold Operation (Virtual Linear Pump) Command

Value via Communications

Program Virtual Linear Pump Virtual Linear Pump Settings

During a properly configured Virtual Linear Pump operation while operating

in the Process Hold mode and using communications for system control, this

parameter establishes the Virtual Linear Pump level.

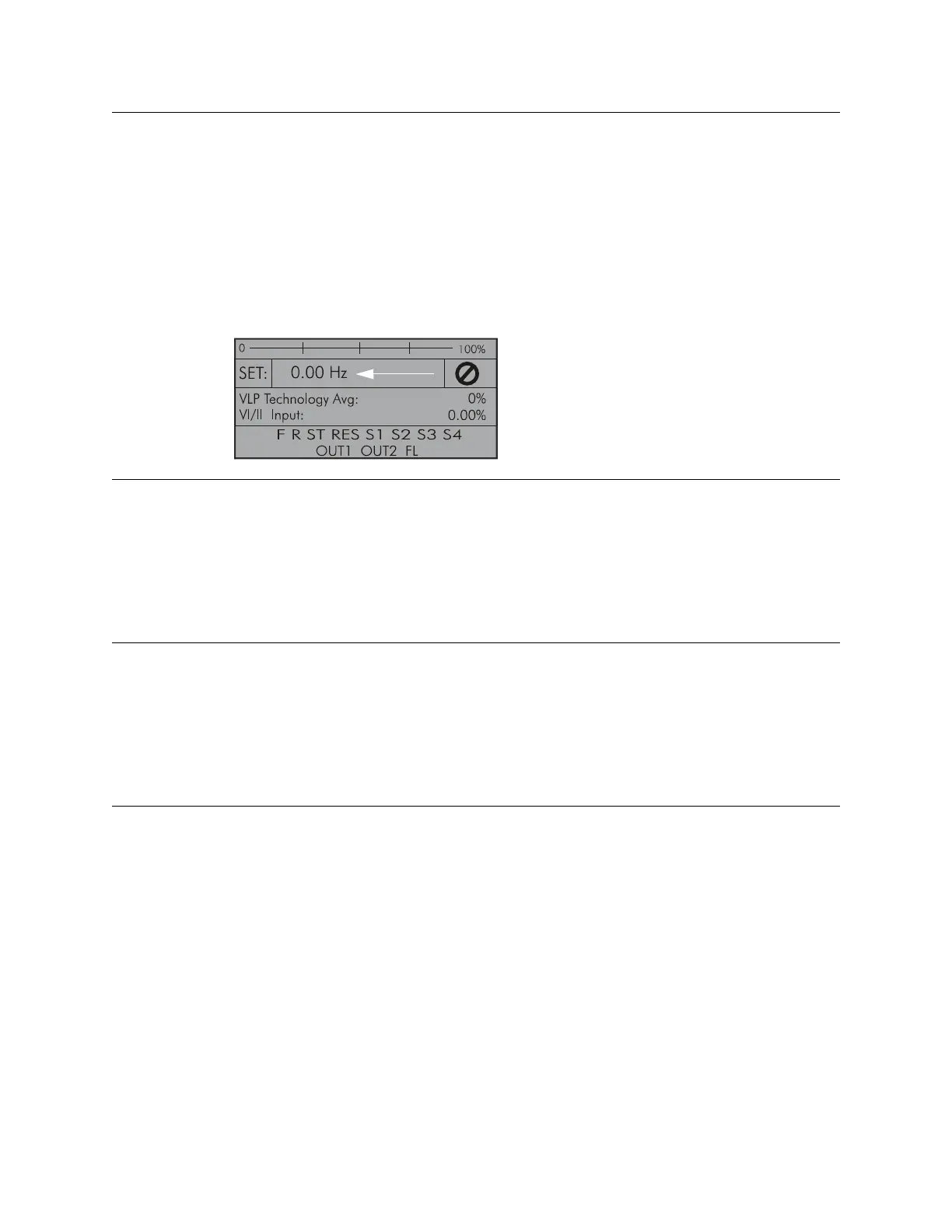

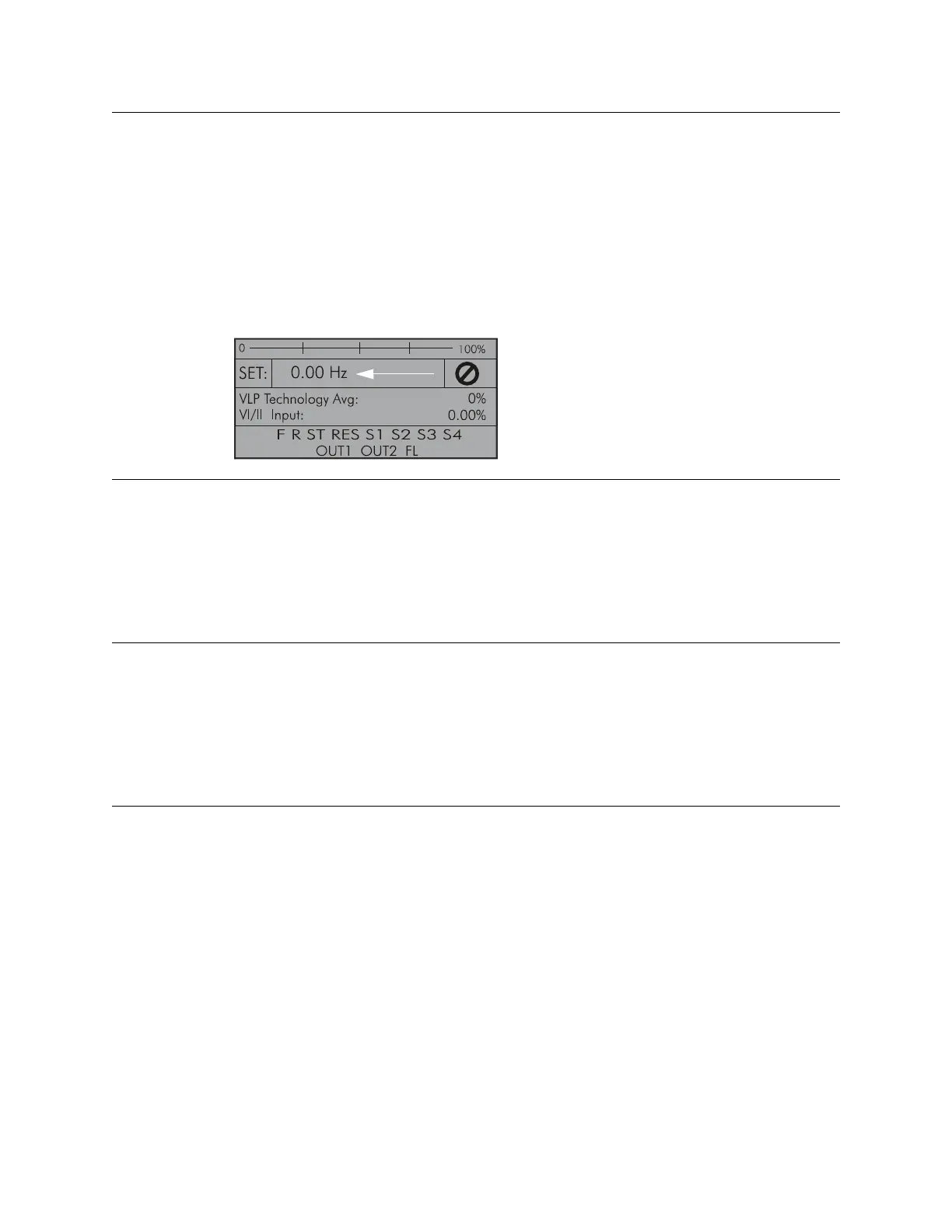

This parameter setting is effective ONLY while operating in the Process Hold

mode and while receiving a command via communications. The end value of

this parameter setting appears in the Frequency Command screen as shown

below.

Direct Access Number — F487

Parameter Type — Numerical

Factory Default — 0.0

Changeable During Run — Yes

Minimum — F403 Setting

Maximum — F393 Setting

Permanent Magnet (PM) Motor Constant 1

Program Motor PM Motor

This parameter is used with synchronous motor applications only.

Contact the TIC Customer Support Center for information on this parameter.

Direct Access Number — F498

Parameter Type — Numerical

Factory Default — 100

Changeable During Run — Yes

Minimum — 0

Maximum — 100

Units — %

Permanent Magnet (PM) Motor Constant 2

Program Motor PM Motor

This parameter is used with synchronous motor applications only.

Contact the TIC Customer Support Center for information on this parameter.

Direct Access Number — F499

Parameter Type — Numerical

Factory Default — 100

Changeable During Run — Yes

Minimum — 0

Maximum — 100

Units — %

Acceleration Time 2

Program Special Acc/Dec 1 – 4 Settings

This parameter specifies the time in seconds for the output of the ASD to go

from 0.0 Hz to the Maximum Frequency for the 2 Acceleration profile. The

Accel/Decel pattern may be set using F502. The minimum Accel/Decel time

may be set using F508.

This setting may be adjusted to stabilize unstable Virtual Linear Pump

operation.

This setting is also used to determine the acceleration rate of the UP/DOWN

Frequency Functions.

Note: An acceleration time shorter than the load will allow may cause

nuisance tripping and mechanical stress to loads. Automatic

Accel/Decel, Stall, and Ridethrough settings may lengthen the

acceleration times.

Direct Access Number — F500

Parameter Type — Numerical

Factory Default — (ASD-Dependent)

Changeable During Run — Yes

Minimum — 0.1

Maximum — 6000.0

Units — Seconds

F487 F500

Loading...

Loading...