Installation Mechanical

RTHD-SVX02H-EN 57

Full Heat Recovery Condenser Water Tem-

perature Requirements and Control

D

WARNING

The following application conditions

must be satised, otherwise the unit will

be damaged easily!

1. Operation control of the pump: the operation of the

pump must correspond with the pump start-stop

signal of the UC800 controller of the unit.

2. Setting of water ow switch: the ow switch node

of the unit is not allowed to be short-connected, and

it should be connected with the water system ow

switch, and the ow rate is not less than 60% of the

rated ow when the water ow switch is closed.

3. Establishment time of ow: Time between ow

switch close and water pump runs should not exceed

5 minutes.

4. In addition to the mode switching process, the two

water pumps of the full heat recovery unit are not

allowed to run simultaneously.

Installation Of Water Tank Temperature

Sensor

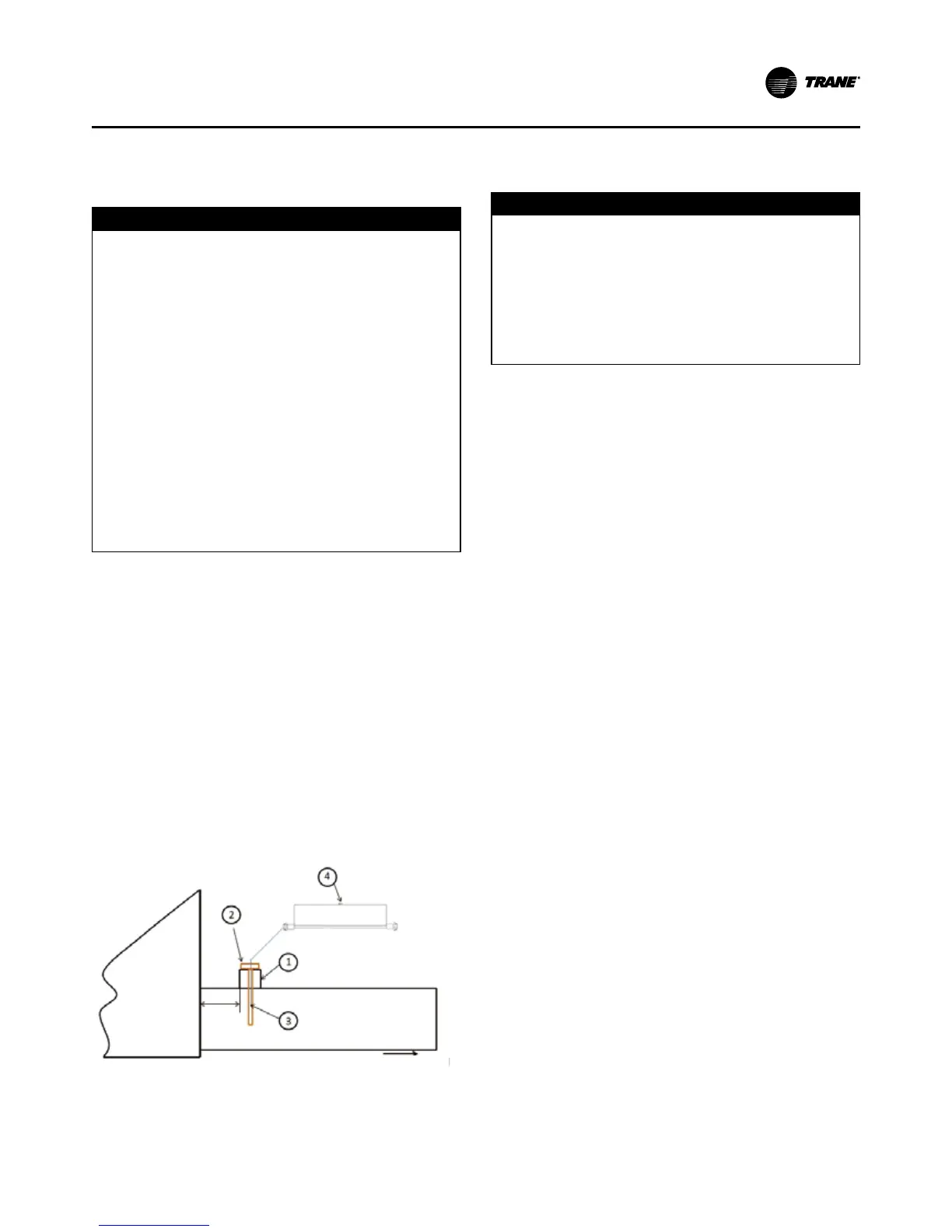

The RTHD full heat recovery unit needs to collect the

temperature of the client’s water tank at run time for load

control, and the installation of the temperature sensor of

the tank can be referenced below.

Part 1 is provided by the customer. The internal thread

specification of the joint and temperature sensor tem-

perature package is 1/2-14NPT. Parts 2, 3, 4 are provided

by Trane. In order to avoid affecting the measurement

accuracy, the distance between the insertion position

of the temperature sensor and the water tank must not

exceed 200mm. The temperature sensor is connected to

the temperature acquisition module by 20 meters long

connecting line, and the temperature of the water tank is

transmitted to the unit control cabinet.

Client water box

Max. 200mm

Receive full heat recovery condenser inlet

1. Temperature sensor temperature well connector.

2. Temperature sensor temperature well.

3. Temperature sensor

4. 20 meters long connecting line.

Water Treatment

D

CAUTION

Proper Water Treatment!

The use of untreated or improperly treated water in a

RTHD may result in scaling, erosion, corrosion, algae or

slime. It is recommended that the services of a qualied

water treatment specialist be engaged to determine

what water treatment, if any, is required. The Trane

Company assumes no responsibility for equipment fail-

ures which result from untreated or improperly treated

water, or saline or brackish water.

Using untreated or improperly treated water in these

units may result in inefficient operation and possible

tube damage. Consult a qualified water treatment spe-

cialist to determine whether treatment is needed.

Water Pressure Gauges and Thermome-

ters

Install field-supplied thermometers and pressure gauges

(with manifolds, whenever practical) as shown in Figure

27. Locate pressure gauges or taps in a straight run of

pipe; avoid placement near elbows, etc. Be sure to install

the gauges at the same elevation on each shell if the

shells have opposite-end water connections.

To read manifolded water pressure gauges, open one

valve and close the other (depending upon the reading

desired). This eliminates errors resulting from differently

calibrated gauges installed at unmatched elevations.

Loading...

Loading...