Installation Mechanical

RTHD-SVX02H-EN 35

Unit Leveling

Note: The electrical panel side of the unit is designated

as the “front” of the unit.

1. Check unit level end-to-end by placing a level on the

top surface of the evaporator shell.

2. If there is insufficient surface available on the top of

the evaporator shell, attach a magnetic level to the

bottom of the shell to level the unit. The unit should

be level to within 1/4” (6.35 mm) over its length.

3. Place the level on the evaporator shell tube sheet

support to check sideto- side (front-to-back) level.

Adjust to within 1/4” (6.35 mm) of level frontto- back.

Note: The evaporator MUST be level for optimum heat

transfer and unit performance.

4. Use full-length shims to level the unit.

Water Piping

Piping Connections

D

CAUTION

Equipment Damage!

To prevent equipment damage, bypass the unit if using

an acidic ushing agent.

Make water piping connections to the evaporator and

condenser. Isolate and support piping to prevent stress

on the unit. Construct piping according to local and na-

tional codes. Insulate and flush piping before connecting

to unit.

Use grooved pipe connectors for all water piping con-

nections. Evaporator and condenser water inlet and

outlet sizes and locations are shown by the unit submit-

tals and in Figure 13 through Figure 18. The designation

in the tables corresponds to the compressor frame code

followed by the evaporator shell code followed by the

condenser shell code as given in the unit model number,

digits 6, 7, 14, 15, 21 and 22. Table 13 gives additional

water connection information.

Reversing Water Boxes

All water boxes may be reversed end-for-end. Do not

rotate water boxes. Remove the sensors from the wells

before removing the water box. Complete the water box

switch and replace the sensors. See Figure 13 through

Figure 18 for correct orientation of the water inlet and

outlet.

If the water boxes are reversed, be sure to properly re-

wire the water temperature sensors in the control panel.

Note: Be certain to replace water boxes right-side-up

to maintain proper baffle orientation. Use new

o-rings.

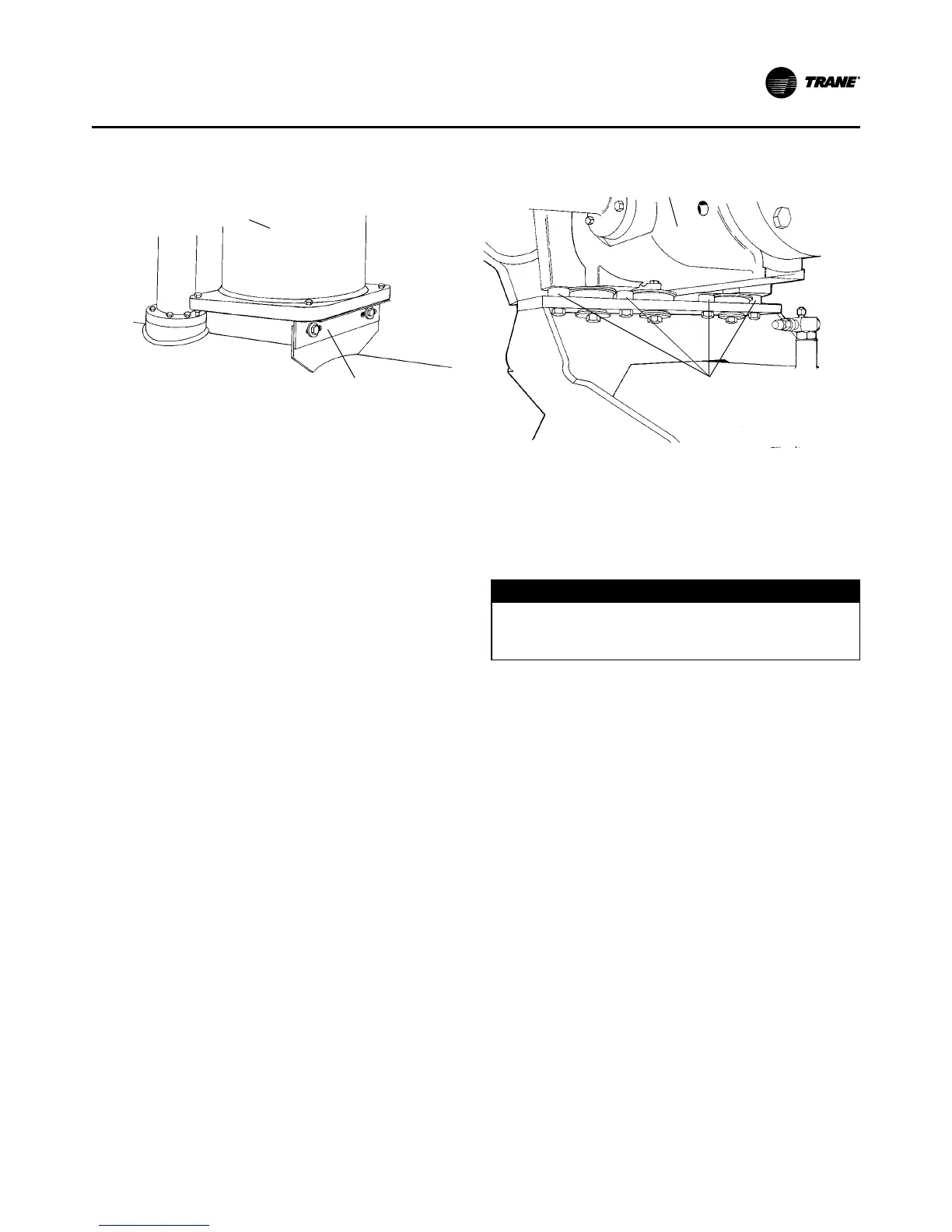

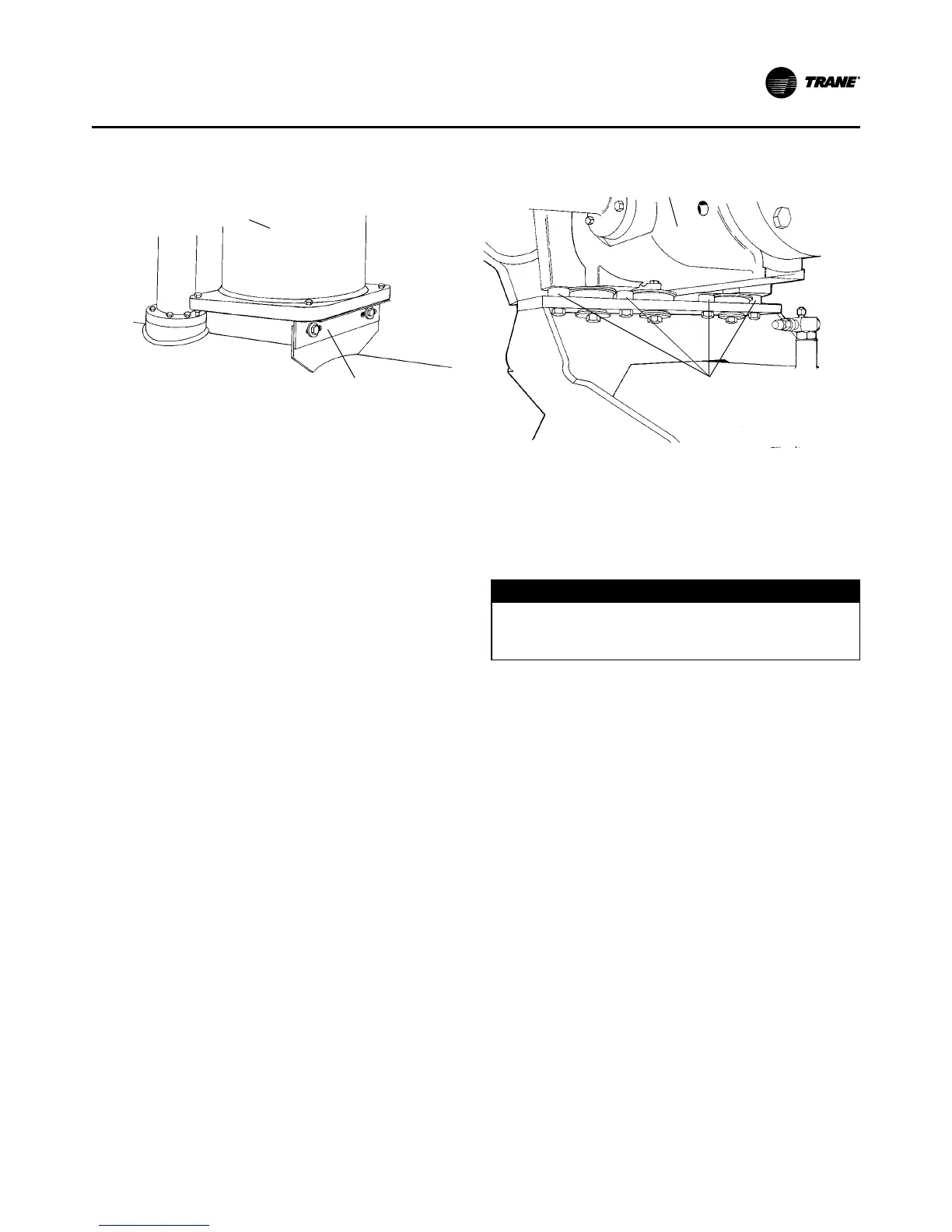

Figure 12. Oil Separator with Shipping Bracket and Compressor Shipping Spacer

Shipping Bracket

Oil Separator

Remove 4 Shipping

Spacers (only 3 on B

Loading...

Loading...