Installation

48 SO-SVN048A-EN

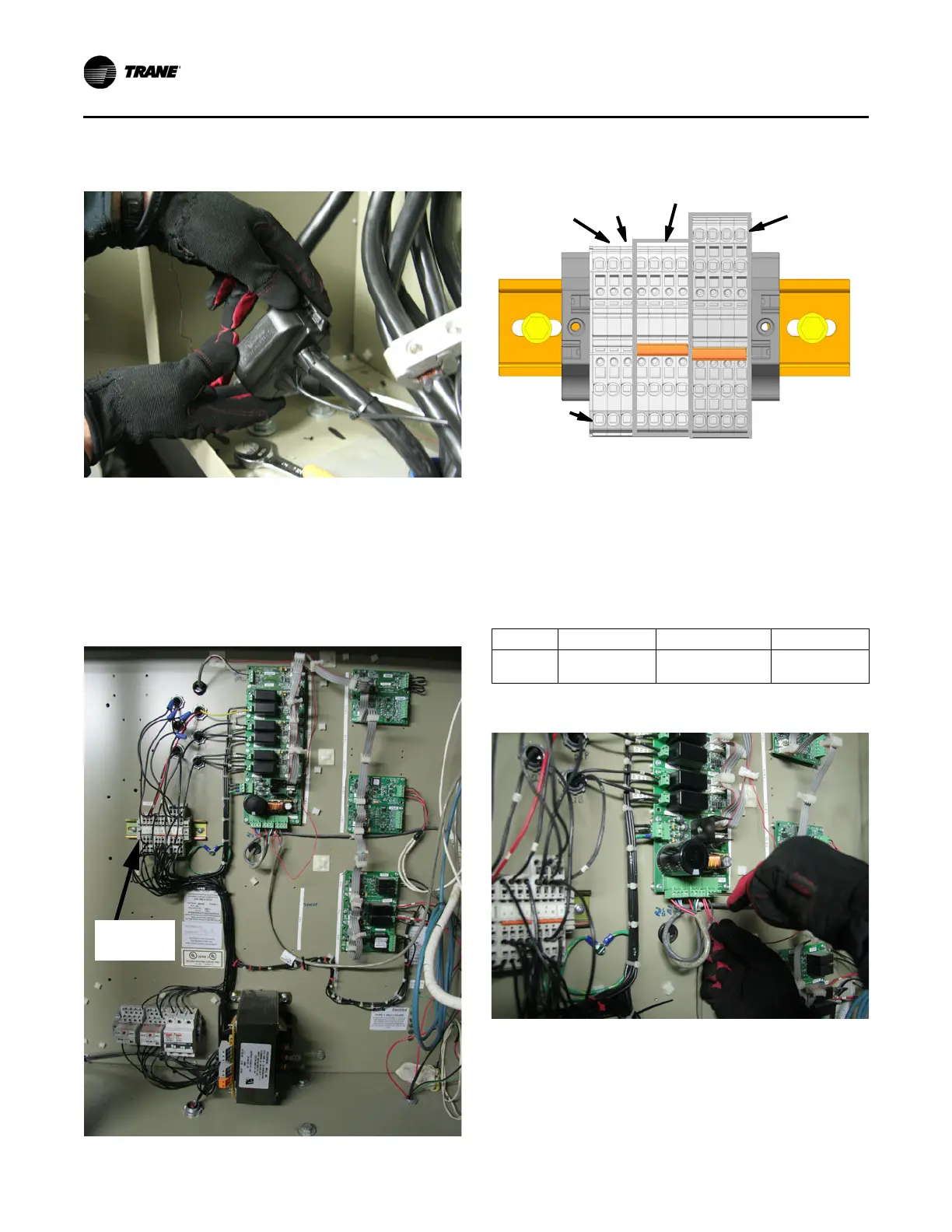

4. Install wire tap case; refer to Figure 70.

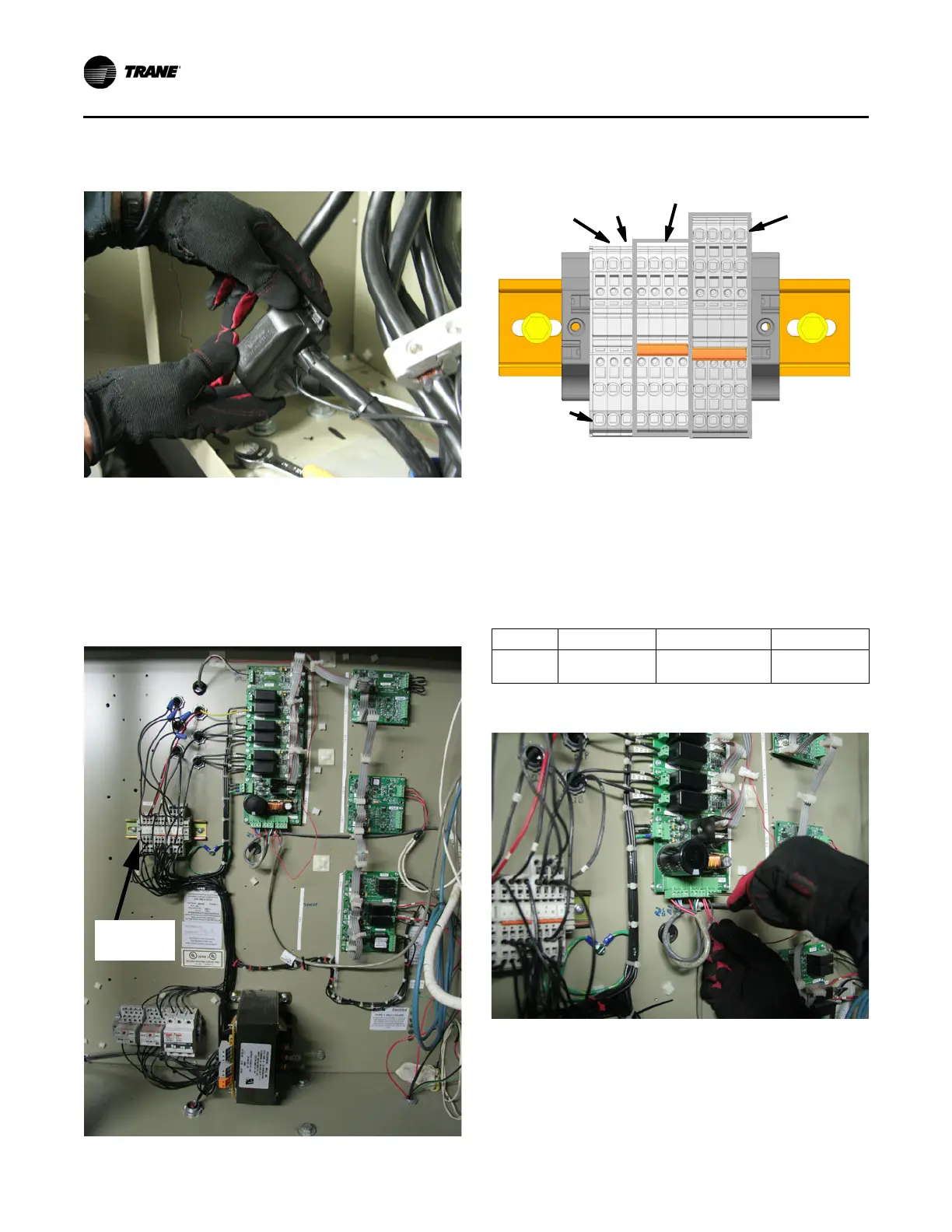

Note: The following connections will be connected to some

Terminal 1X5. Terminals 1X5-4 through 1X5-7 are

electrically tied together and are connected to terminal

X1 of the control power transformer (115V hot).

Terminals 1X5-8 through 1X5-11 are electrically tied

together and connect to terminal X2 of the control

power transformer, (115V com); refer to Figure 71.

Oil Loss Liquid Level Sensor Connections

5. Reconnect the oil loss liquid level sensor 24V supply to

power supply 1A2 connector J5, Pin 1; this is a red wire

(64A) and was previously connected to the starter module

J3 Pin 1.

Note: J3 or J4 Pin 1 on power supply 1A2 may also be

used for oil loss liquid level sensor connection.

1K15 Relay Connections

6. Using 16 AWG wire, make the following connections listed

in Tabl e 1 2.

Figure 70. Wire tap case install

Figure 71. 1X5 Terminal location

Figure 72. Terminals 1X5-1 through -11

Table 11. Pin-out, oil loss liquid level sensor (4B2)

Wire Description Mating Connection Description

64A (Red) Sensor 24v+ in

J5, Pin 1,

Power Supply (1A2)

24V+ out

Figure 73. Oil loss liquid level sensor connection

1234567 891011

1X5-2 Primary

Oil Sol (4Y3)/

Dual Relay (1A8)

1X5-3 HP

Cutout (4829)

Tied 1X5-4 through -7 Electrically Tied

(115V = “Hot”)

1X5-8 through -

11 Electrically

Tied (115V -

Com)

1X5-1 Heaters

(4E1, 4E2)

Loading...

Loading...