S9V2-SVX001-1B-EN

37

10. Using a leak detection solution or soap suds, check

for leaks at the pressure outlet boss and pressure

tap test screw.

11. Turn on system power and check operation of the

unit.

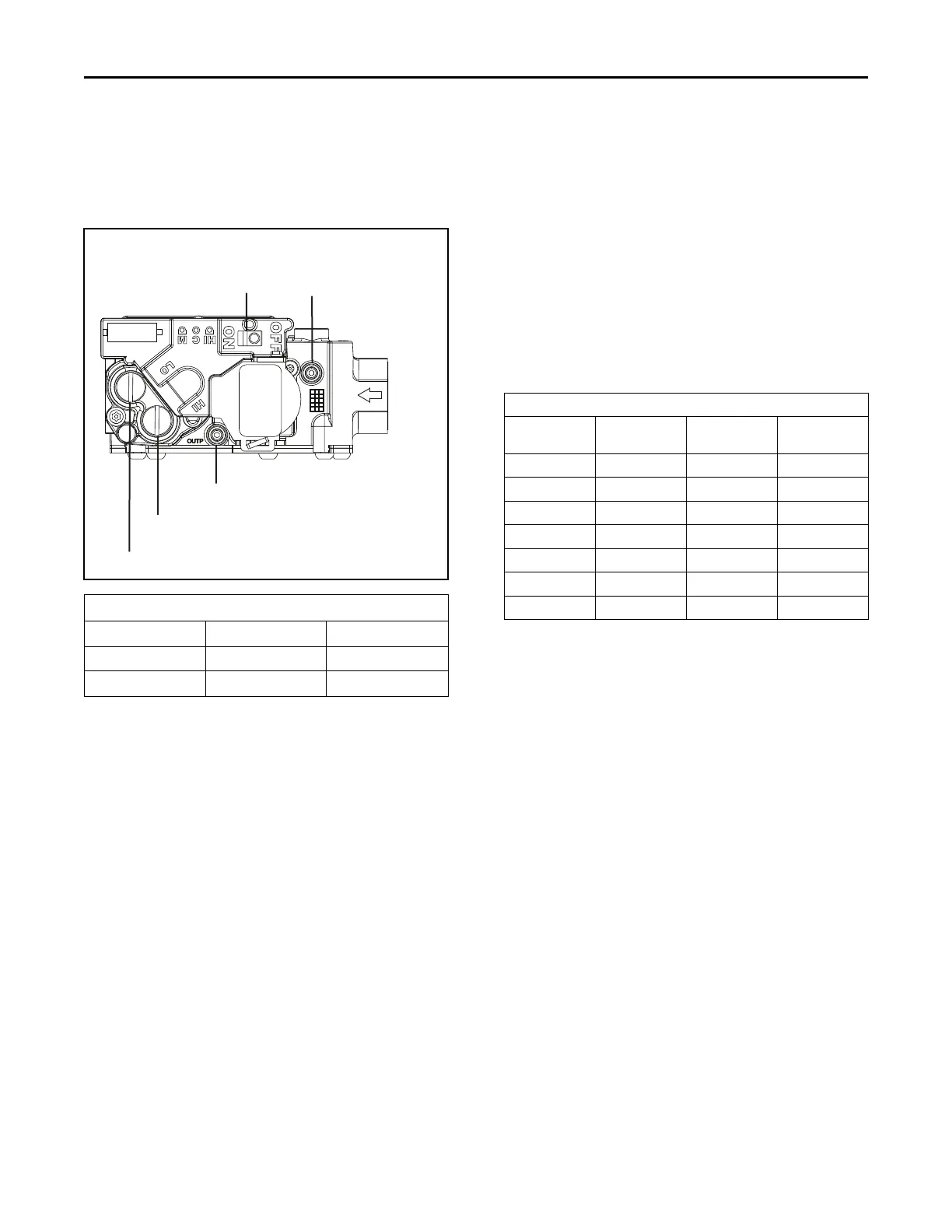

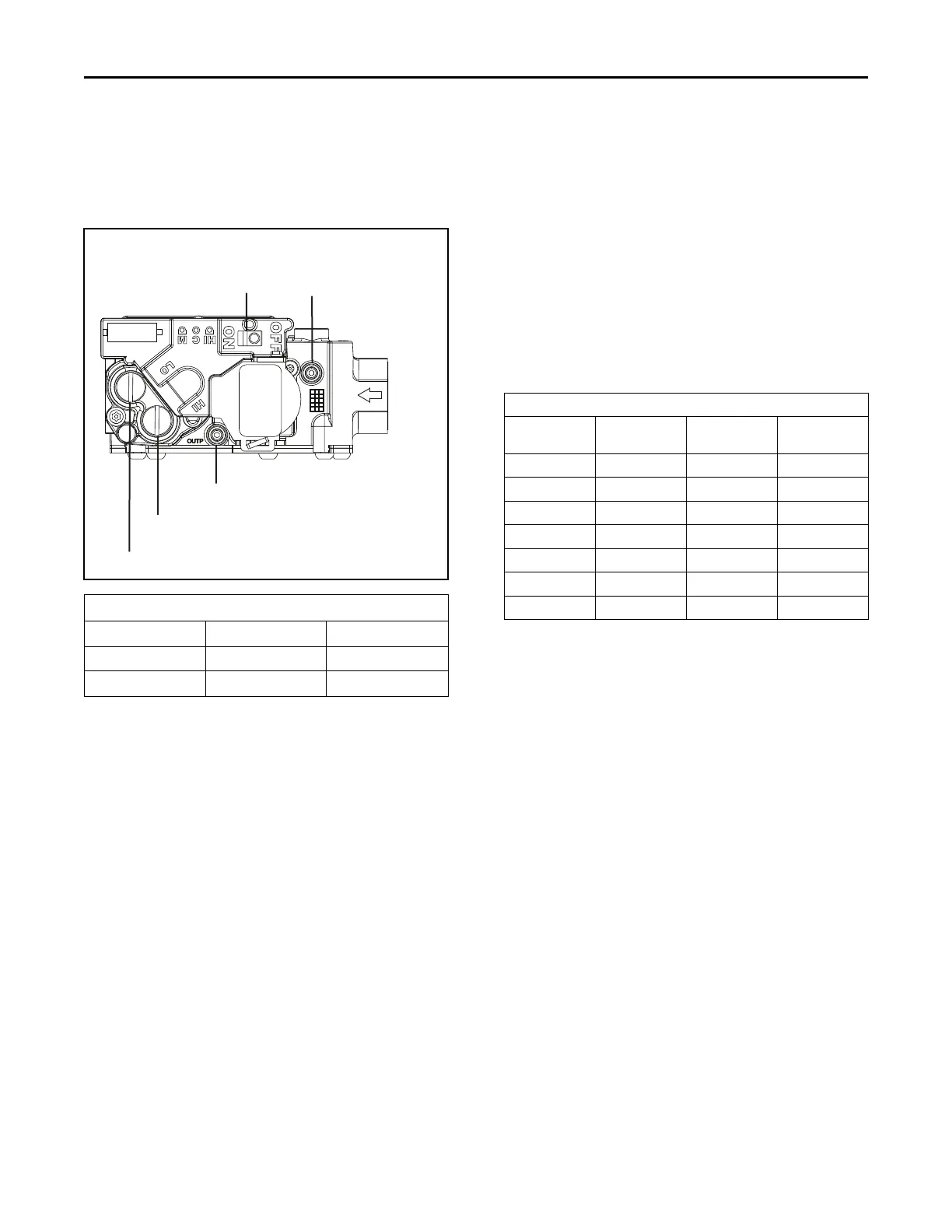

Outlet Pressure Boss

2nd Stage (HI) Manifold Pressure Adjustment

1st Stage (LO) Manifold Pressure Adjustment

Inlet Pressure

Boss

Gas Valve On/Off

Toggle Switch

White-Rodgers 36J

Fuel Manifold Pressure Settings (inches w.c.)

Fuel 2nd Stage Max. 1st Stage Max.

Natural Gas 3.5” W.C. 1.7” W.C.

Propane Gas 10.0” W.C. 6.0” W.C.

High Altitude Derate

Input ratings (BTUH) of these Furnaces are based on

sea level operation and should not be changed at

elevations up to 2,000 ft. (610 m).

If the installation is 2,000 ft. (610 m) or above, the

Furnace input rate (BTUH) shall be reduced 4% for each

1,000 ft. above sea level.

Installations of this furnace at altitudes above 2,000 ft.

(610 m) shall be made utilizing the Vent Length table

and/or Part Numbers for Replacement Orifices table in

these installation instructions.

The Furnace input rate shall be checked by clocking the

gas flow rate (CFH) and multiplying by the heating

value obtained from the local utility supplier for the gas

being delivered at the installed altitude. Input rate

changes can be made by adjusting the Manifold

Pressure (min 3.0 - max 3.7 in. W.C. - Natural Gas) or

changing orifices (orifice change may not always be

required).

If the desired input rate can not be achieved with a

change in Manifold Pressure, then the orifices must be

changed. Propane installations will require an orifice

change.

IImmppoorrttaanntt:: Reinstall the replacement orifices to the

same depth as the orifices supplied with

the equipment.

See the table for help in selecting orifices if orifice

change is required. Furnace input rate and temperature

rise should be checked again after changing orifices to

confirm the proper rate for the altitude.

The vent length table shows the required vent lengths

for installations at various altitudes. Installations above

12,000 feet are not allowed.

PART NUMBERS FOR REPLACEMENT ORIFICES

DRILL SIZE PART

NUMBER

DRILL SIZE PART

NUMBER

44 ORF00501 54 ORF00555

45 ORF00644 55 ORF00693

46 ORF00909 56 ORF00907

47 ORF00910 57 ORF00908

48 ORF01099 58 ORF01338

49 ORF00503 59 ORF01339

50 ORF00493

Turn the main Gas Valve toggle switch within the unit

to the "OOFFFF" position. Turn the external gas valve to

"ON". Purge the air from the gas lines. After purging,

check all gas connections for leaks with a soapy

solution – DDOO NNOOTT CCHHEECCKK WWIITTHH AANN OOPPEENN FFLLAAMMEE..

Allow 5 minutes for any gas that might have escaped to

dissipate.

Propane Gas being heavier than air may require forced

ventilation. Turn the toggle switch on the Gas Valve in

the unit to the "ON" position.

The table in next page lists the main burner orifices

used with the furnace. If a change of orifices is required

to correct the furnace input rating refer to the part

number for replacement orifices table.

Installation of this furnace at altitudes above 2000 ft

(610m) shall be in accordance with local codes, or in

the absence of local codes, the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or National Standard of Canada,

Natural Gas and Propane Installation Code, CSA

B149.1.

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Loading...

Loading...