RLC-

VU006A-E4

1

ntr

l

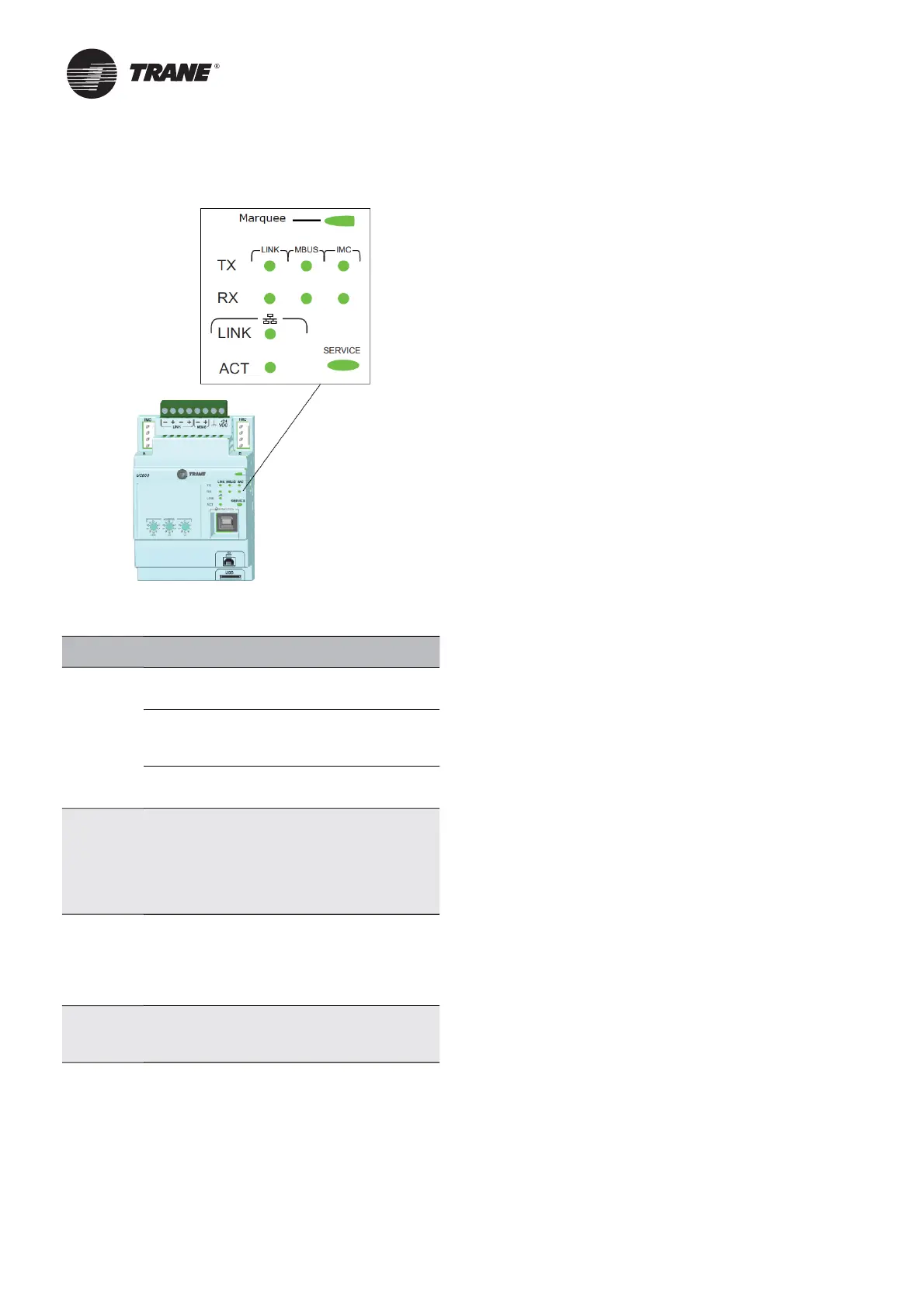

C800 Statu

ar

uee

wered. If the Marquee LED is

reen solid,

the UC800 is

owered and no

roblems exist.

ow

ower or malfunction

If the Mar

uee

ED is red solid, the UC800 is

owered, but

there are

roblems

resent.

larm. The Mar

uee LED blinks Red when an

l

rm exists.

,

BU

, IM

Th

LED blinks

reen at the data transfer

rate when the UC800 transfers data to other

evices

n the link.

Th

LED blinks

ellow at the data transfer

rate when the UC800 receives data from

ther

evices

n the link.

th

rn

t

ink

Th

LED is solid

reen if the Ethernet

link is connected and communicatin

.

Th

CT LED blinks

ellow at the data

tr

nsfer r

te when

t

fl

w is

ctive

n the

link.

ervice

The Service LED is solid

reen when pressed.

or

ualifi ed service technicians onl

. Do not

s

.

NOTICE

ectrica

oise

Maintain at least 6 inches between low-volta

e (<30V)

and high voltage circuits. Failure to do so could result in

e

ectrica

noise that cou

d distort the signa

s carried by

the low-volta

e wirin

, includin

IPC.

Tracer TD7 Operator Interfac

nformation is tailored to o

erators, service technicians,

nd owners

hen operatin

a chiller, there is specifi c information

you need on a day-to-day basis—setpoints, limits,

iagnostic information, and reports.

ay-to-day operational information is presented at the

isplay. Logically organized groups of information—

chiller modes o

operation, active diagnostics, settings

nd reports put in

ormation conveniently at your

ngertips

Tr a c

r™ T

The RTHD o

erator interface allows for daily o

erational

as

s and setpoint chan

es. However, to adequately

service chillers

racer

service tool is re

uired.

(Non-Trane

ersonnel, contact your local Trane offi ce

for software

urchase information.) Tracer TU adds a

level of so

histication that im

roves service technician

effectiveness and minimizes chiller d

wntime. This

ortable PC-based service-tool software su

orts service

nd maintenance tasks, and is required

or so

tware

up

rades, confi

uration chan

es and major service

s

s

Tracer TU serves as a common interface to all Trane

chillers, and will customize itself based on the properties

of the chiller with which it is communicating. Thus, the

service technician learns only one service interface.

he panel

us is easy to trou

leshoot usin

sensor

verifi cation.

nly the defective device is replaced. Tracer

can communicate with individual devices or

roups

f devices.

All chiller status, machine con

guration settings,

customiza

le limits, and up to 100 active or historic

iagnostics are displayed through the service-tool

s

tware inter

ace.

s and their respective

racer

indicators visually

con

rm the availability o

each connected sensor, relay,

nd actuat

r.

racer

is designed to run on a customer

s laptop,

connected to the Tracer control

anel with a USB cable.

Your laptop must meet the

ollowin

hardware and

so

tware requirements:

1 GB RAM

minimum

1024 x 768 screen res

uti

CD-R

M driv

Ethernet 10

100 LAN c

rd

An available U

B 2.0

ort

Microsoft® Windows® XP Professional operation

system with Service Pack 3 (SP3) or Windows 7

Enterprise or Professional operatin

system (32-bit or

64-bit)

Microso

t .NET Framework 4.0 or later

Loading...

Loading...