CNT-SVX12C-EN 63

Chapter 9

PID control

This chapter will help you set up, tune, and troubleshoot proportional,

integral, derivative (PID) control loops used in the Tracer ZN517 unitary

controller. For more information about PID loops, see BAS-APG002, PID

Control in Tracer Multi-Purpose Controllers.

PID control requires the use of a Rover service tool. All PID factory

defaults can be restored by clicking the Use Defaults button.

What PID loops do

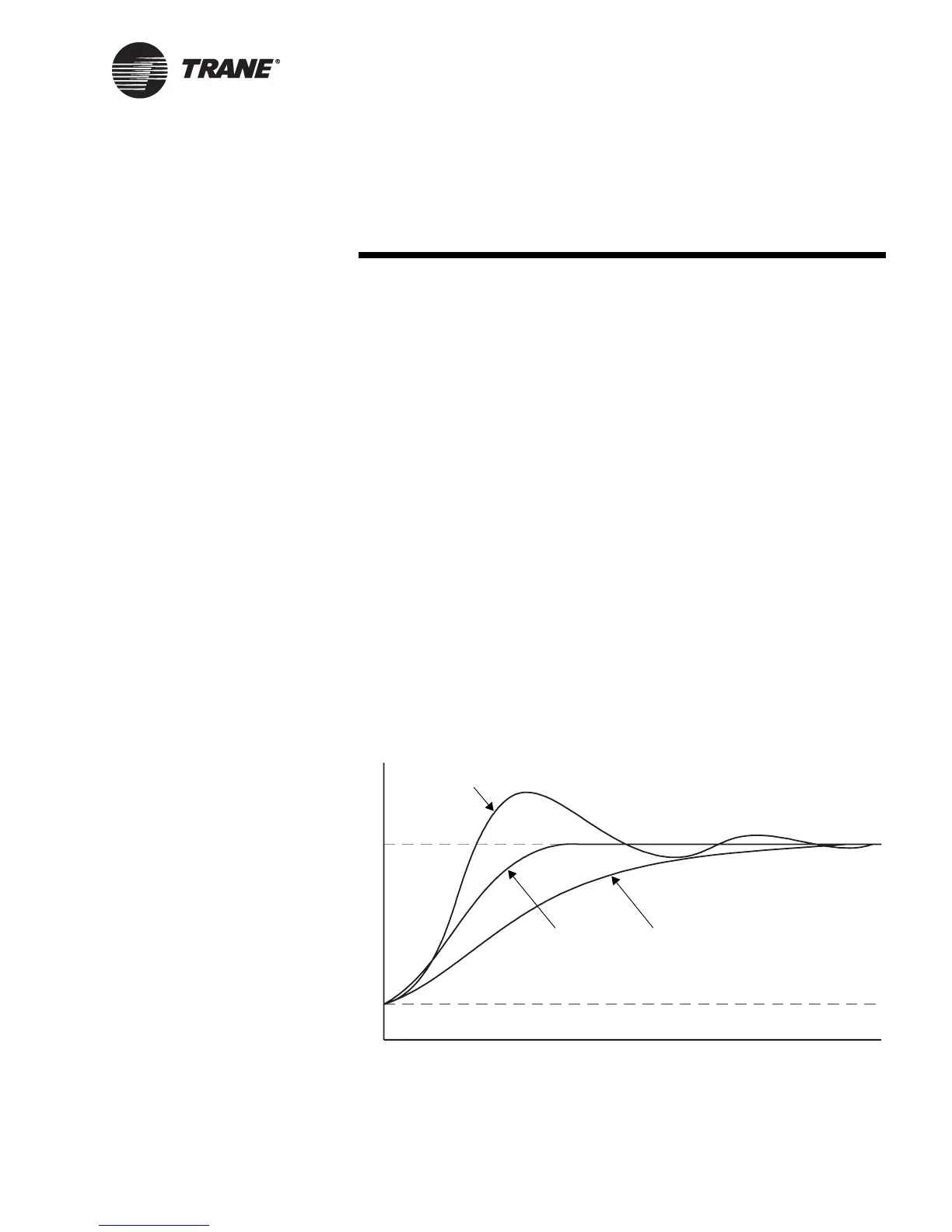

A PID loop automatically controls an output to maintain a measured

value at its setpoint by monitoring the error (the difference between the

measured value and the setpoint). The loop performs proportional, inte-

gral, and derivative calculations to determine how aggressively to change

the output.

The goal of PID control is to reach the setpoint as quickly as possible

without overshooting the setpoint or destabilizing the system and to

maintain the setpoint consistently over time. If the system is too aggres-

sive, it will overshoot the setpoint as shown in Figure 19. If it is not

aggressive enough, the time to reach the setpoint will be unacceptably

slow.

Figure 19. The effects of PID aggressiveness

Setpoint

Initial point

Too aggressive (overshoot)

Too slow

Time

Ideal response

Measured value

Loading...

Loading...