EMISSION AND

EVAPORATIVE

LOSS

CONTROL

SYSTEMS

"--:;:

=5:::::--_.",

"",""""

I

",'1M

: L

--;.~,,;"~.~

•

...,f\~

I

.,,"'"

I

.,"~

.

L

."""n

..

,.

.

.,

.................

Fig. 7 Electric fuel

pump

..-,

......

n

.......

,,.

"--.------111·

""

Electric

Fuel

Pump

Operation

The

fuel

pump

IS

energIsed, .ndependant

of

the electrOniC

control

Unit, from an output terminal on the combined relay

The

combined relay

IS

the component that

prOVIdes

an

interface between the

main vehIcle electrical harness and

those ,tems that are spec,f,cally related to the electrOniC fuel

injectIOn system. An inertia

SWItch

.s

Included

In

the

CirCUit

to

Isolate the fuel pump and prevent

II

from operattng

In

the

event of an Impact type

accident

The

CIrCUit

is

also routed

through the electrOniC control system Air Flow Meter where a

simple contact

SWitch

ensures that the fuel

pump

cannot

operate when

no

air

IS

flOWing

mto the engine i,e the engine

is

no! running.

ThiS

contact

SWitch

IS

by-passed when the

starter motor

CirCUit

IS

energised

Once the

engine

IS

runnmg a

ClrCUlt

from the Ignl\lon

SWitch

passes through a relay ,aground,via the electroniC control Unit

on

TAl

models When energised th.s relay permIts a

CIrCUIt

to be made to the AIr Flow

Meter

contact

SWItch

ProvIding

the contact switch

IS

closed a

CirCUit

IS

completed through a

second relay,

again

to

ground. When energised thiS second

relay completes the

CirCUIt

to operate the fuel

pump

Under engme starting conditions the Air Flow Meter contact

switch would normally Isolate the fuel

pump

as no air

IS

flowing through the engine.

To

overcome thiS an Input

IS

taken direct from the starter motor

CirCUit

to

energise the

second relay and thus

permit the fuel pump

to

operate during

the engine starting operation

8

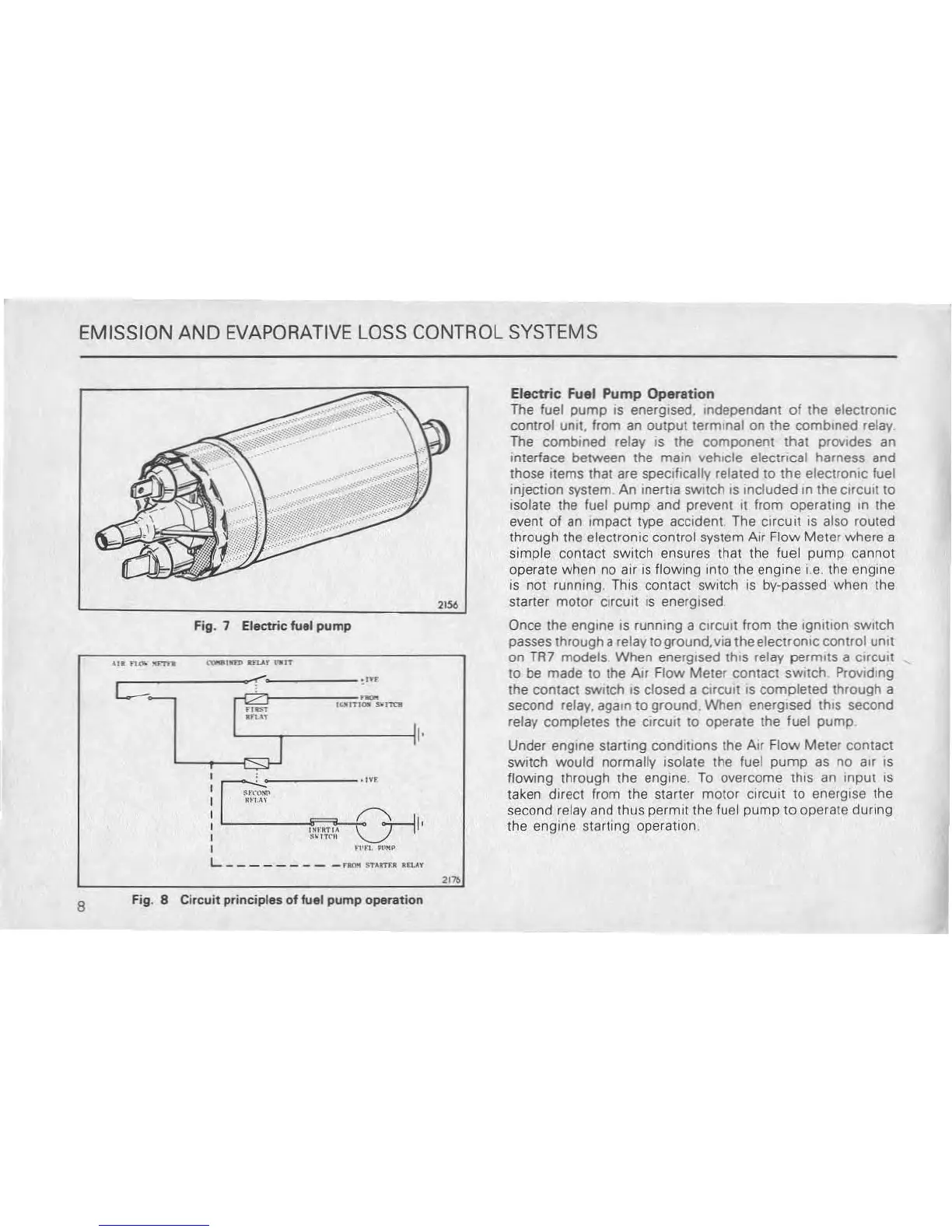

Fig. 8 Circuit

principles

of fuel

pump

operation

Loading...

Loading...