5.5 Maintenance

5.5.1 Utilities

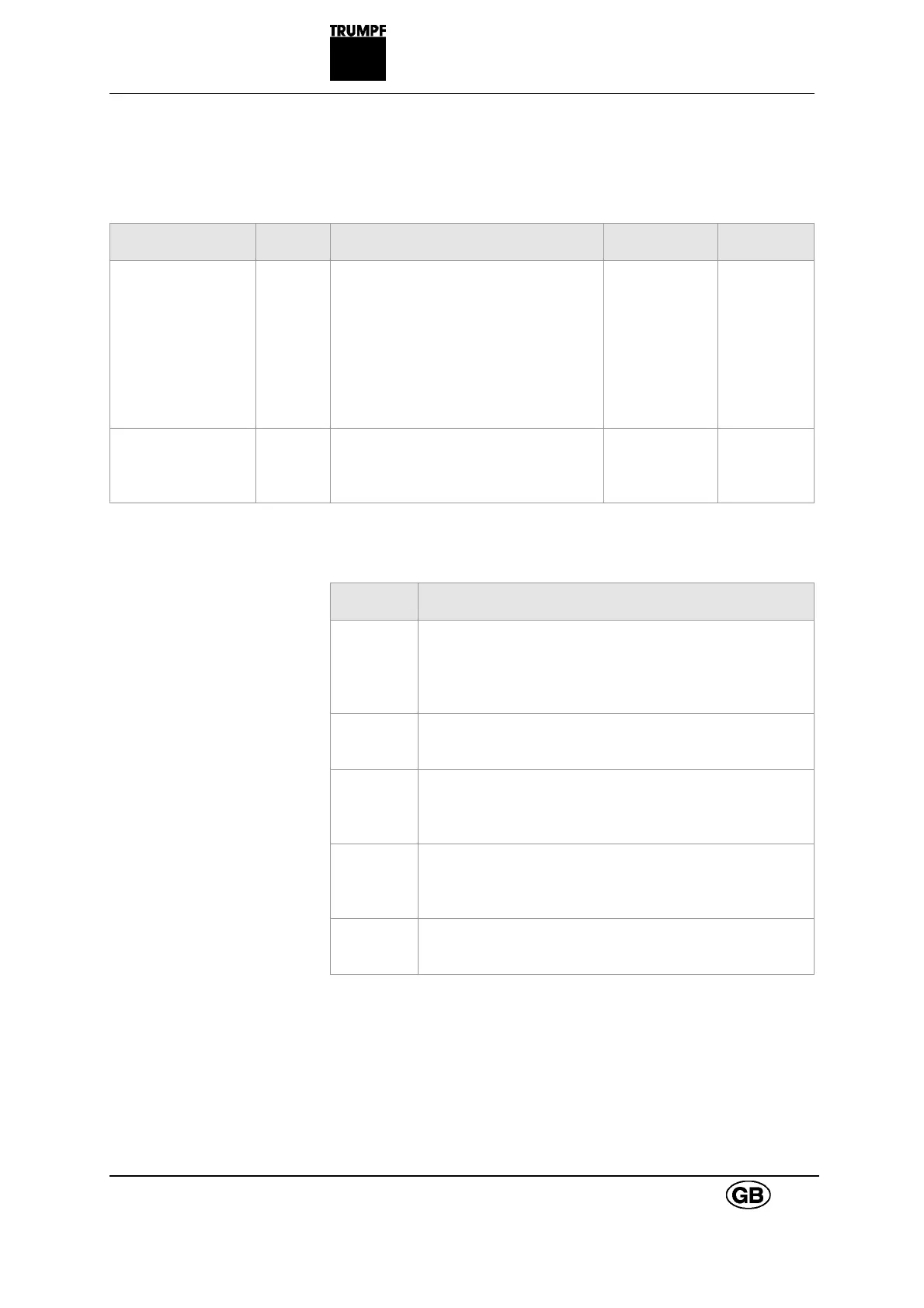

Lubrication point Quantity Recommended lubricant Designation Viscosity

Hydraulic oil container 5 l ARAL Vitam GF 32 or Vitam DE 32 HLP/HLPD ISO VG 32

BP Energol HLP 32 DIN 51525

CASTROL Hyspin AWS 32

ELF ELFOLNA HMD 32

ESSO TERESSO 32

FUCHS RENOLIN MR 10

MOBIL DTE 24 or 25

SHELL Tellus Oil DO 32 or DO 46

Grinding coolant 0.7 l / Henkel P3-MULTAN 41-3

container 20 l CASTROL Syntilo 81-E

(oil for grinding coolant)

5.5.2 Maintenance intervals

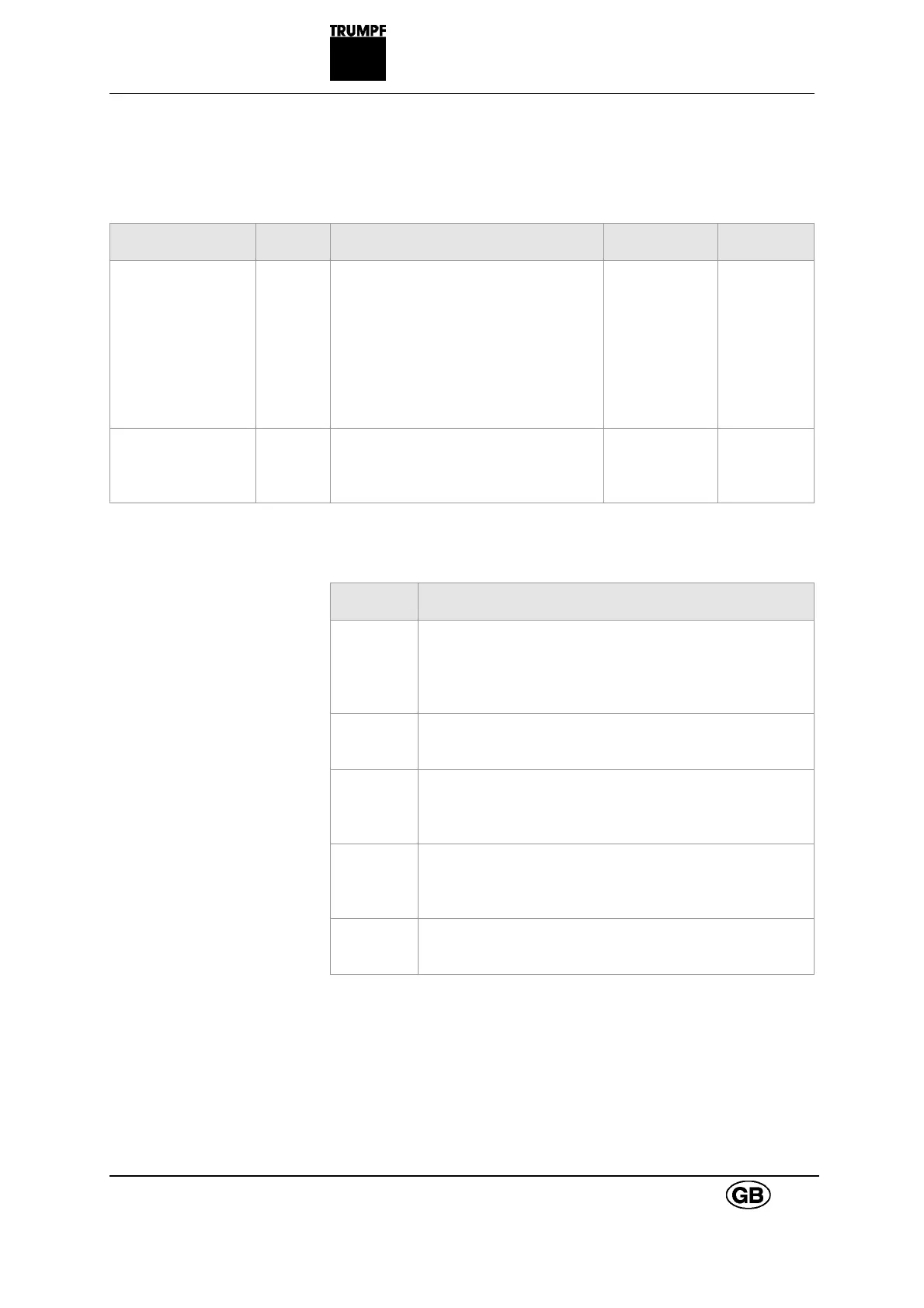

Interval Work to be done

After 8 h • Take the dirt bowl out of the rotary tool holder and rinse it out

• Check the hydraulic oil and grinding coolant

• Replace filter paper in coolant container as soon as filtration

effect diminishes

After 40 h • Clean the entire machine

• Lubricate locating stop using a grease gun

After 160 h • Clean the grinding coolant container

• Change the coolant, assure proper disposal of waste grinding

coolant

After 500 h/ • Remove hood, raise the motor bridge and

half-yearly lubricate ball bearings with slideway oil

• Check the fittings on the pumps for proper seating

After 4000 h • Replace the hydraulic oil and bleed the system at

the throttle valve, assure proper disposal of waste oil

B60E quicksharp 17

Loading...

Loading...