16

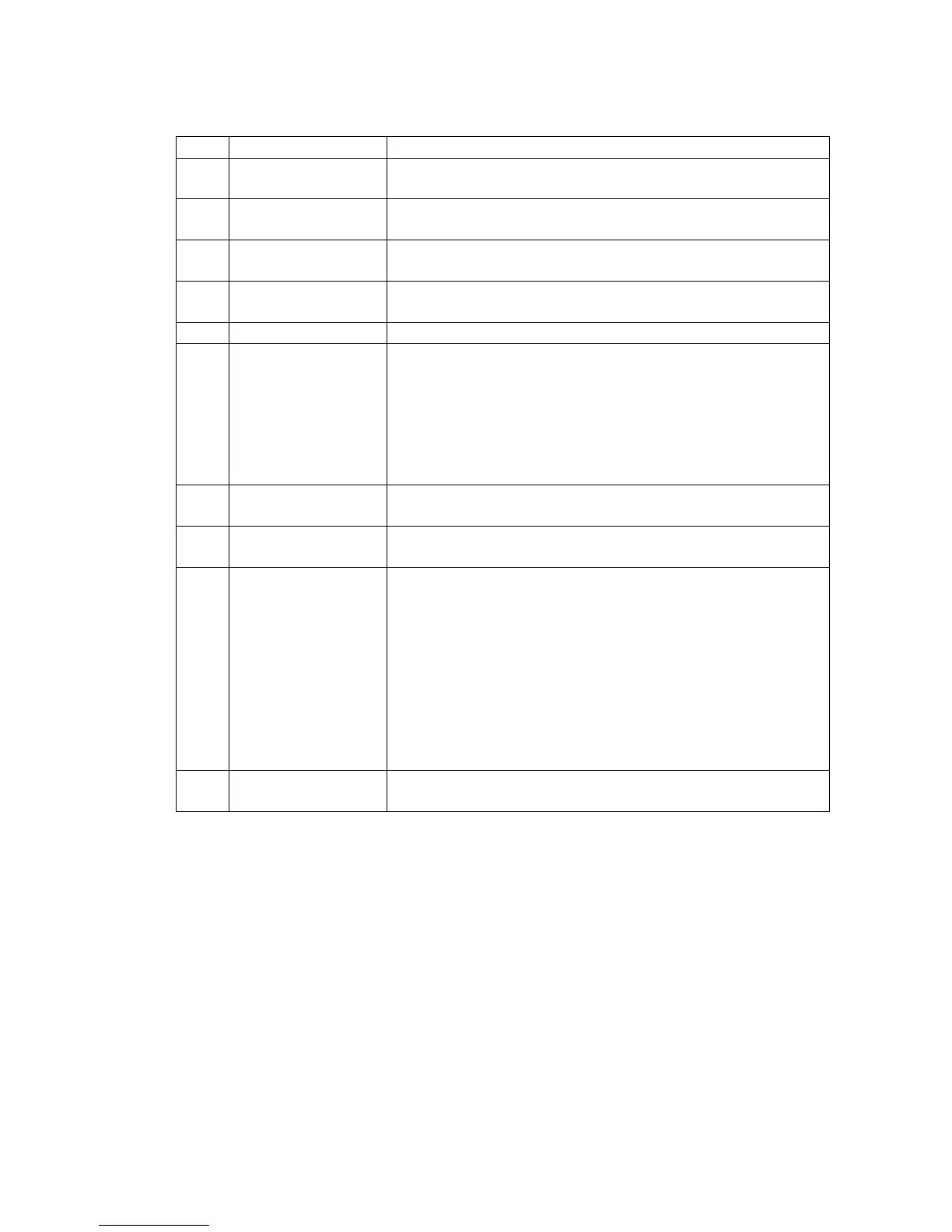

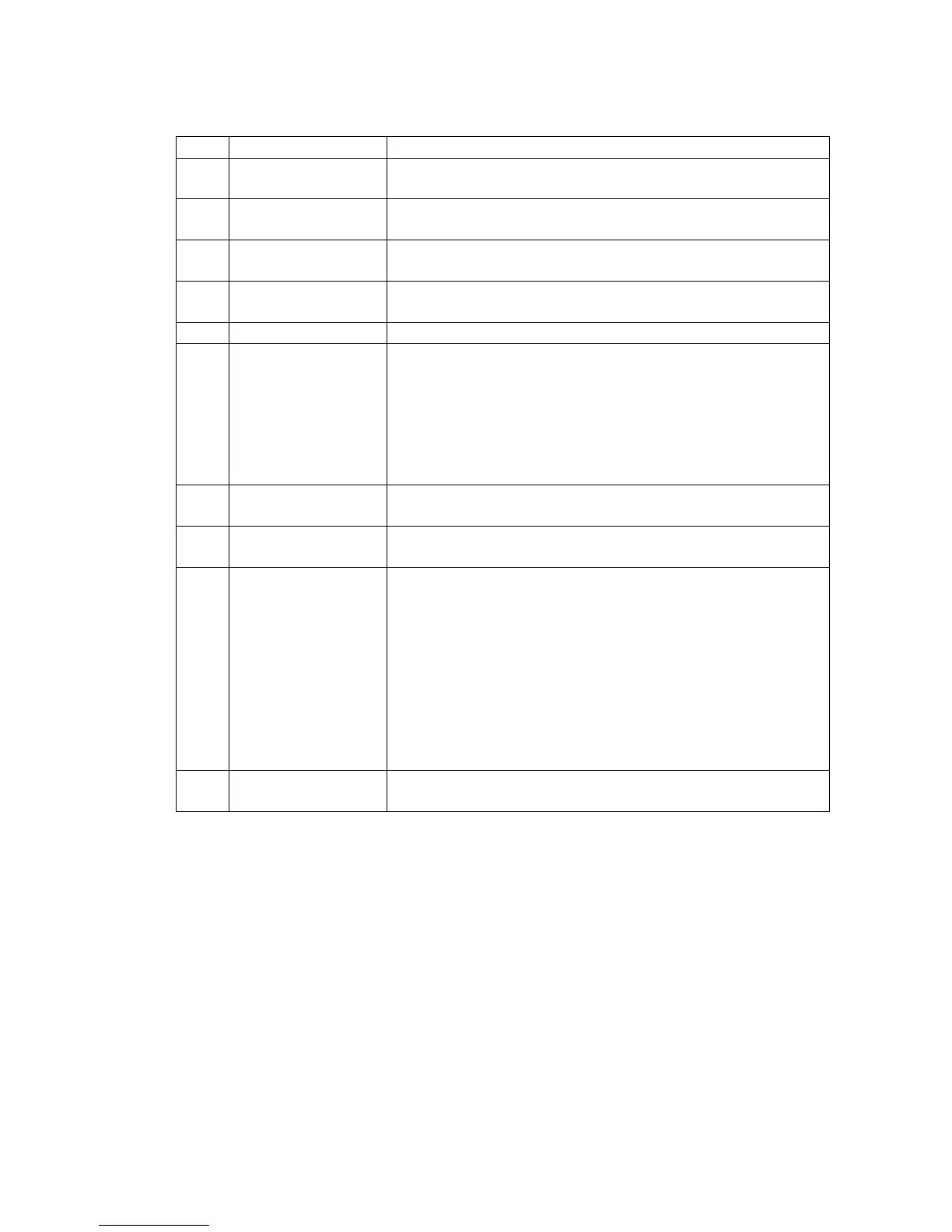

3.3.2 Install the Peripherals

Installing steps of peripherals

Connect air supply to input point.

Fill lubrication system..

Remove the mount blocks in X- & Z-axis; don’t remove the

wooden block that supports the spindle head.

Mount and install

the wiring lines

Follow the wire numbers connecting and mounting the

dismantled wires/pipes.

After checking the electric control lines, connect them.

Turn on power to

make test run

a. Certify the correctness of power phases.

b. Certify the correctness of motor turning direction.

c. Check if pipe connectors are connected correctly and

locked tight; mechanism locations are correct

(mechanism should be located at respective location

normally).

d. Lift the tool post head; take out the supporting pads.

Certify track

lubrication

Check if the lube system feeds lube oil? Are two lube oils

distributed properly?

Clean the anti-rust oil on jaw chuck & tool post; clean up

dust on Machine and wipe it clean.

a. First, manually return Machine’s three axes back to

HOME point manually in slow speed.

b. Return the two axes back to HOME point by 100% fast

speed; certify if the HOME points are same.

c. Check if stroke of each axis follows the set one? If

over-stroke is effective?

d. Follow the attached parameter table to check if

controller’s display meets the parameter table or not?

e. Are the spinning directions and speed of positive/reverse

turns normal?

During running, follow the precision inspection table to

make commissioning run.

Loading...

Loading...