6-24 Electrostatic Classifier Model 3082 and SMPS Spectrometer Model 3938

Performing a Leak Check

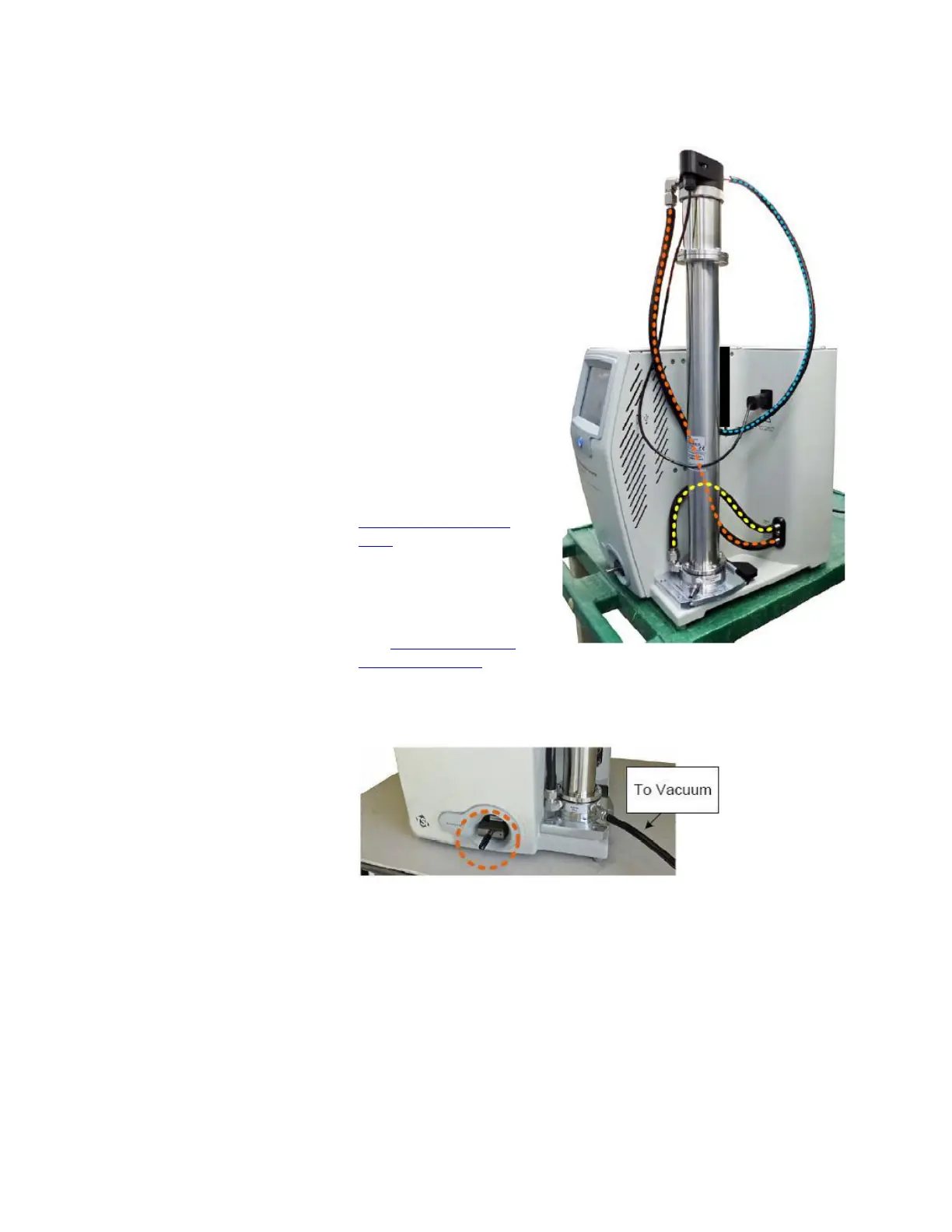

Zero test failures can be due

to a leak in either the sheath

flow path or the aerosol flow

path. A vacuum leak check

can be performed to

determine if a zero count

failure is due to a leak.

Per ISO 15900, a system

leak check procedure can be

performed as follows:

1. Power off the classifier

and disconnect it from

the CPC.

2. Install your DMA,

connecting the sheath

flow ports and

polydisperse flow port to

the classifier. See

Chapter 2: Installing a

DMA for details.

3. Install your neutralizer to

complete the internal

flow path, either

3077/3077A or 3088.

See Chapter 2: Setting

Up the Instrument for

details.

4. Install the inlet adapter. Cap the inlet with a vinyl end cap or other

plug/cap.

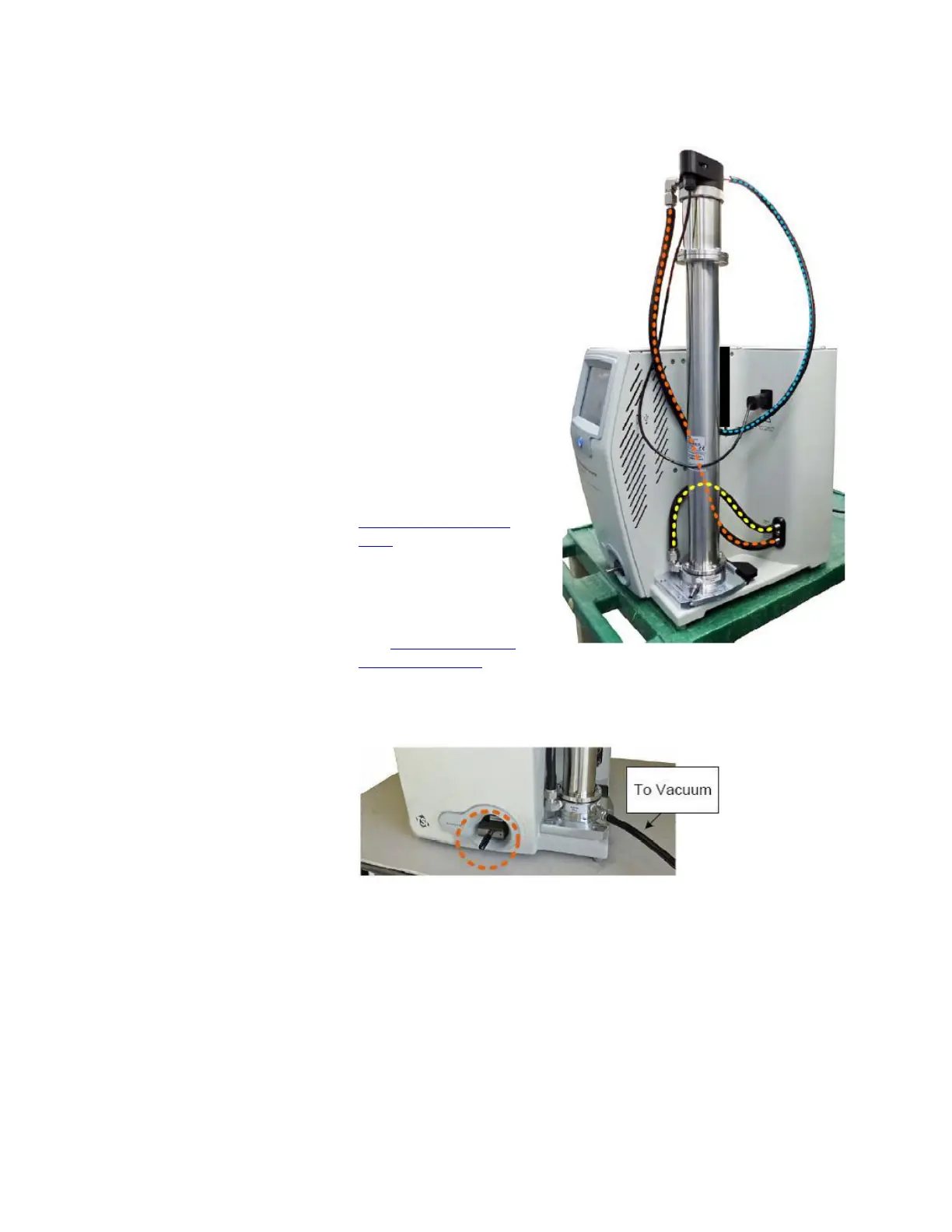

5. Connect the DMA monodisperse outlet to a vacuum system (not

provided) capable of pulling down to less than 10% of atmospheric

pressure (<10 kPa).

6. Seal off the classifier from the vacuum source.

7. Monitor the pressure of the vacuum system using a manometer. The

leakage rate is acceptable if the pressure inside the classifier system

changes by less than 5% per hour.

Loading...

Loading...