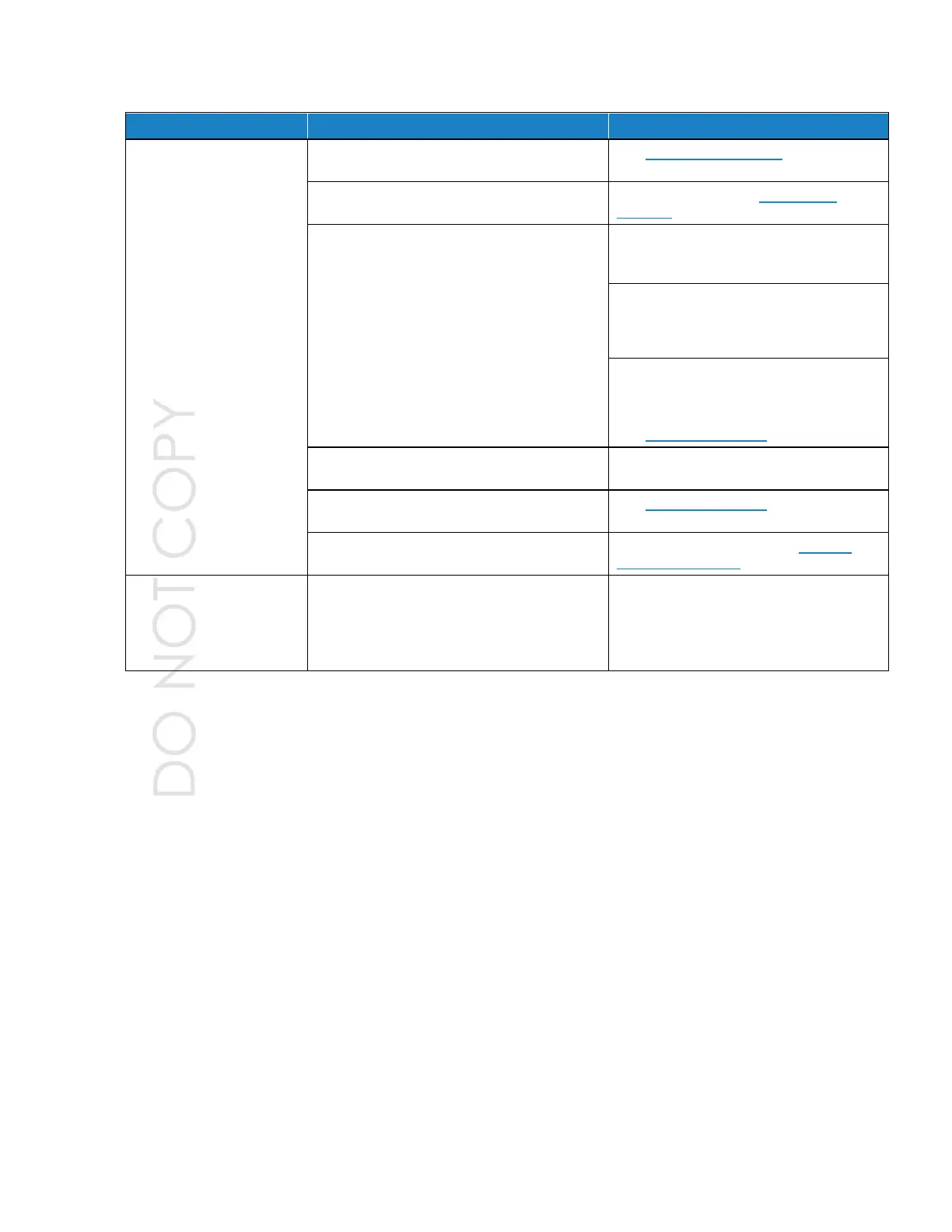

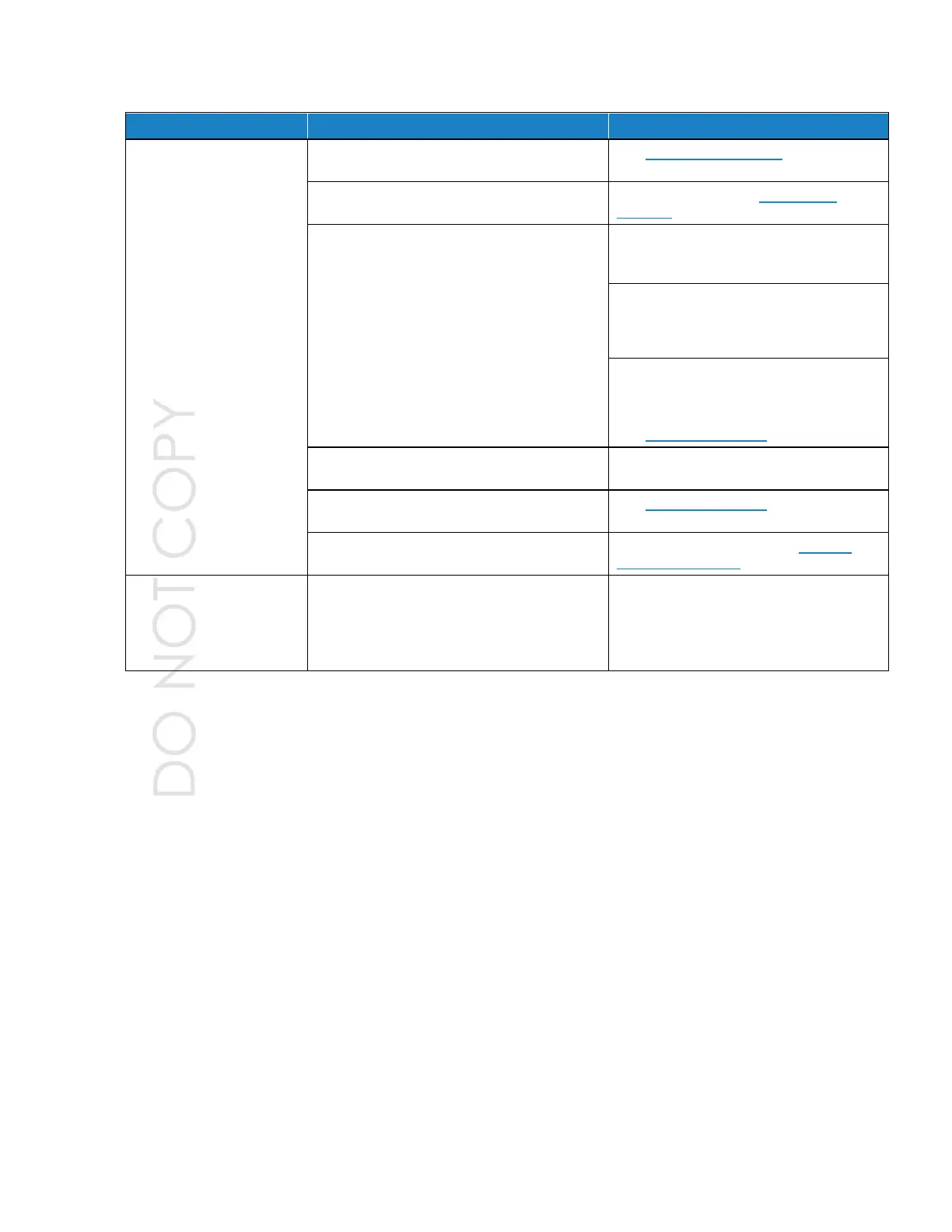

Internal optics have become dirty

See Optics Block Cleaning for cleaning

details

Instrument has contamination on the optics

due to condensation or excessive loading

Clean instrument. See Optics Block

Cleaning.

Tubing from the pump inlet is not

connected to the outlet nozzle or tubing is

leaking (Model 9303).

Remove obstruction from inlet and/or re-

calibrate flow. If there is no flow or the

flow rate is too low, replace pump

assembly.

Reset laser power.

Check laser cable to detector board.

Replace laser assembly.

See Laser Replacement.

Laser is set at incorrect laser power or the

laser is damaged

Laser has become misaligned due to

excessive bumps or jolts

Detector board malfunction

Replace detector board. See Detector

Board Replacement.

Counts are too high or

cannot zero unit

Contamination in the optics chamber,

clean optics.

Deposits in the inlet—clean inlet and

check for dents on the inlet. If inlet is

dented, replace the inlet.

Loading...

Loading...