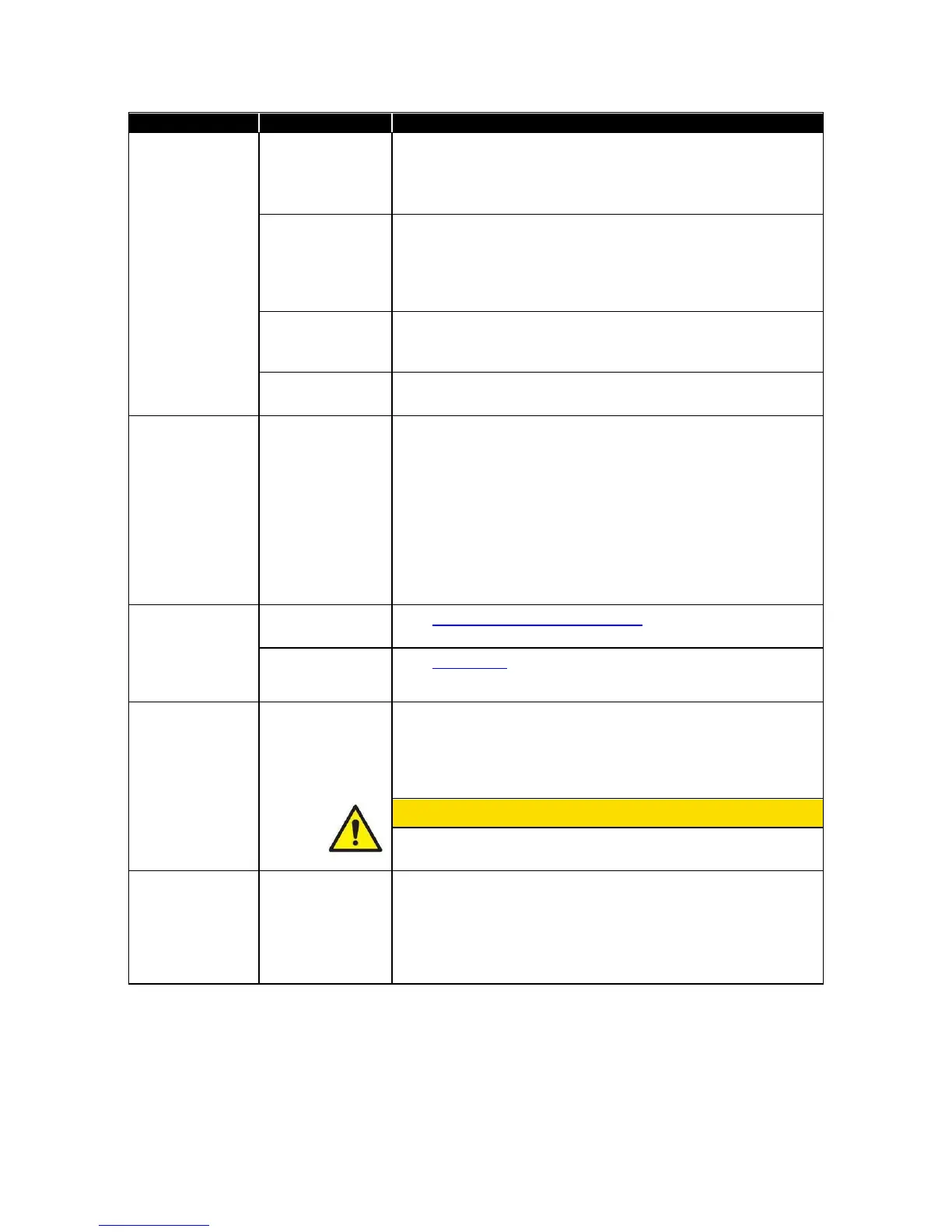

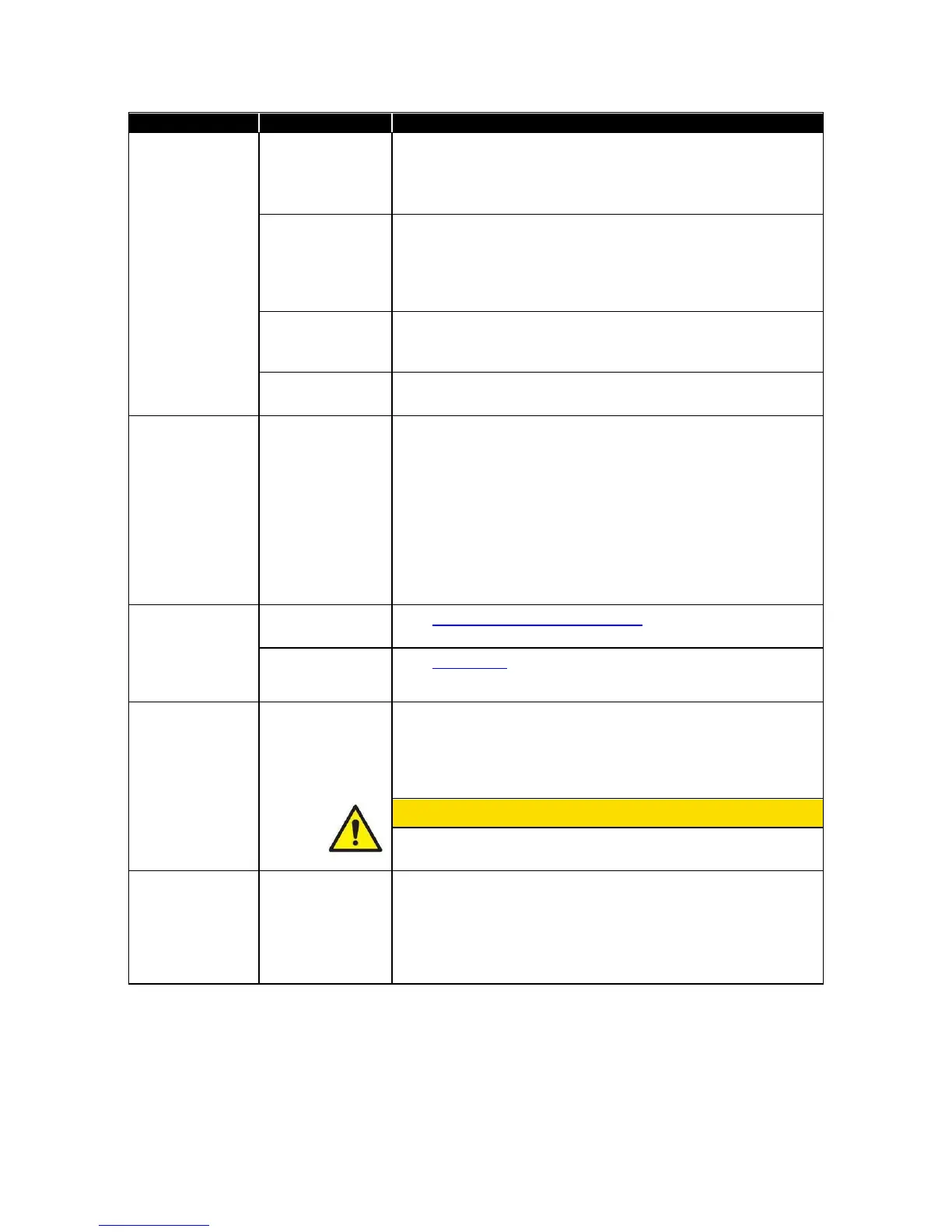

Technical Section

Displayed room

pressure or flow

wildly

fluctuating.

Supply or

Exhaust system

unstable.

Go to DIAGNOSTICS menu, FLOW CONTROL item to take

manual control of the supply and exhaust control devices. If

room pressure stabilizes, supply or exhaust system is not

stable. Verify reference pressure is stable.

Supply air is

affecting the

sensor.

Check location of supply air diffusers. They should be

located as far from the pressure sensor as is realistic,

10 feet preferred with 6 feet minimum. Supply diffuser

terminal throw velocity must be less than 10 ft/min at the

sensor. Relocate supply or exhaust as needed.

Display

averaging is

very short.

Lengthen the time constant by entering the

CONFIGURE menu, DISPLAY AVG item, and increase the

average time.

Controller needs

calibration.

Analog output

does not work

properly.

Controller is

connected to

incompatible

equipment.

Enter the DIAGNOSTICS menu, Temp Control item. Use

the TEMP button to adjust Analog Output 3 and the Supply

button to adjust Analog Output 2. Change the output value

while measuring the output with a multimeter. If the voltage

(current) changes, the controller is functioning properly.

If the voltage (current) does not change, disconnect the

analog out device and repeat the above procedure. If

voltage now changes, the controller is good, and the

external device is defective. If no change occurs, DIM is

defective.

Displayed

velocity does

not match

measured

velocity.

Pressure sensor

is dirty.

See Maintenance and Repair Parts.

Controller is not

calibrated.

“LON

OVERRIDE

ON” on the

display

BAS

Communications

have taken

control of

RPC30.

Release control at BMS to clear.

Adequate room pressure differential may not be maintained

while LON overrides the control signal.

Monitor does

not

communicate

with TSI

Configuration

Software

Replace cable with TSI P/N 700036.

Loading...

Loading...