19

06

Troubleshooting

Manual 1807 Rev B p/n 001807 0000

SYMPTOM PROBABLE CAUSE REMEDIES

Pump stalls

Electrical power loss Check power at the pump.

Pump malfunctioning

Contaminated pump

oil or insufcient

lubrication

See Stalling on page 17. See V-Belt on page 7

and Changing the Oil on page 14.

Blocked pump

discharge line

Clear the pump discharge line. Check the oil mist

eliminator element for blockage.

Pump will not start

Electrical failure

Check for power at the pump. Check the motor start

controls and motor.

Pump ooded with oil

Clear oil from the pump by turning over by hand or

disassembling the pump. See Flooding on page 15.

Excessively low

temperature

Heat the pump to minimum starting temperature of

50°F (10°C).

Oil discharged from oil

mist eliminator

Excess oil on discharge

side of oil mist

eliminator

Unscrew the oil mist eliminator and pour oil through the

discharge tting back into the pump.

Reduce pump inlet pressure below 10 Torr to allow

collected oil to drain back through the integral check

valve in the oil mist eliminator.

Table 6-1– Common Symptoms and Remedies

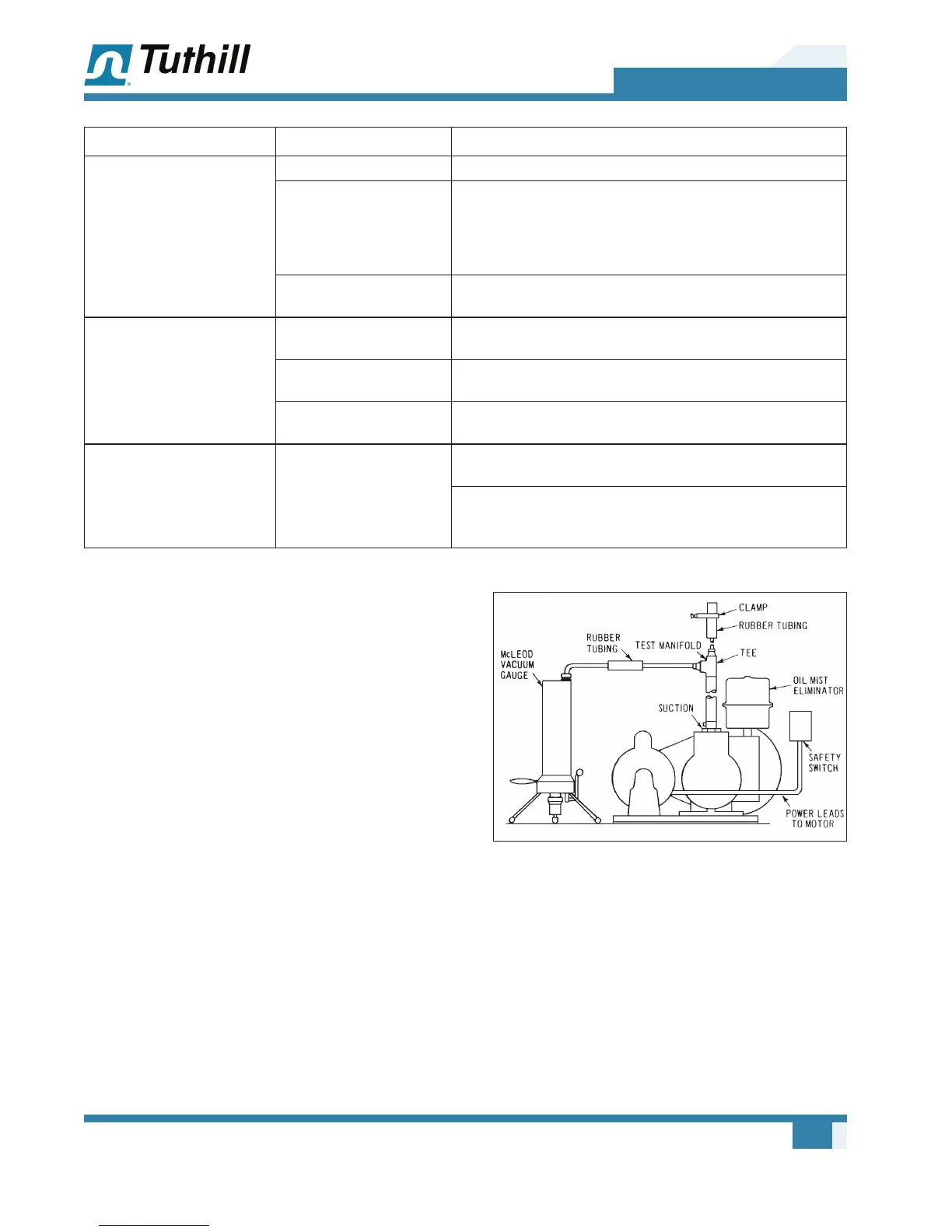

CHECKING PUMP PERFORMANCE

If the processing time increases or the ultimate

pressure becomes poor with no recent changes

in the process or in the system conguration, test

the pump to determine whether the trouble is in

the pump or the connected process equipment. To

check the condition of the pump, use a McLeod

gauge to measure the blank-off pressure as

described in the following procedure.

OTE: N If possible, also read the blank‑off

pressure with a thermistor or

thermocouple gauge. See Figure 6-1 and

Table 6-1 for common faults in vacuum

systems.

Figure 6-1 – Pump Test Manifolding

To read the pump blank-off pressure:

1. Close off the pump inlet by means of a vacuum

valve or short segment of manifolding, as

shown in Figure 6-1.

2. Connect a vacuum gauge to the pump side of

the valve or manifolding. Position the gauge

connection so that it will not become ooded or

blocked by splashing pump oil.

Loading...

Loading...