Manual 2007 Rev B p/n 2007

6

Refer to specifi c data sheets for fl ow capacities

and vacuum capacities.

OTE: N See Figure 4-2 on page 7 for proper

rotation and orientation in inlet and

discharge.

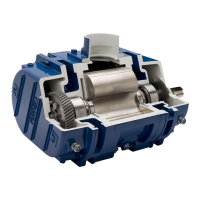

Tuthill Vacuum & Blower Systems model 7000

rotary lobe blowers are positive displacement type

blowers, whose pumping capacity is determined

by size, operating speed, and differential pressure

conditions. Blowers employ rotors rotating in

opposite directions within a housing closed at the

ends by end plates.

The inlet to the discharge is sealed with operating

clearances that are very small. Internal lubrication

is not needed, as there is no moving contact.

Clearances between the rotors during rotation are

maintained by a pair of accurately machined helical

timing gears, mounted on the two shafts extended

outside the air chamber. The intermeshing rotary

lobes are designed to rotate and trap air or gas

between each rotor and the housing. As the rotor

lobes rotate past the edge of the suction port, the

trapped air or gas is essentially at suction pressure

and temperature. Since the blower is a constant

volume device, the trapped air remains at suction

pressure until the leading rotor lobe opens into the

discharge port. The close clearances between the

rotors inhibit back slippage of the trapped volume

from between the rotors and the trapped volume

is forced into the discharge piping. Compression

occurs not internal to the blower but by the amount

of restriction, either downstream of the blower

discharge port or upstream of the blower inlet port.

Figure 4-1 illustrates the air movement within the

machine. The air moves not between the rotors

but between the rotors and the side of the housing.

Also, the machine is bi-directional, meaning that

the direction of rotation of the blower can make

either side the inlet or discharge. See also Figure

4-2 on page 7.

Never attempt to control capacity by means of a

throttle valve in the intake or discharge piping.

This will increase the power load on the drive

system, will increase operating temperatures,

and can overload and/or seriously damage the

blower. Likewise, if a possibility exists that fl ow

to the blower inlet may be cut off during normal

operation of a process, install an adequate vacuum

relief valve near the blower. A pressure-type relief

valve in the discharge line near the blower is also

recommended for protection against cutoff or

blocking in this line. Use check valves on each

blower when more than one blower is connected to

a discharge line.

When a belt drive is used, blower speed, it is

possible to adjust blower speed to obtain the

desired capacity by changing the diameter of one or

both sheaves, or by using a variable-speed motor

pulley. In a direct-coupled arrangement, a variable-

speed motor or transmission is required, or excess

air or gas may be blown off through a manually

controlled unloading valve and silencer. Gas units

can use bypasses, but some applications may

require additional cooling. If there is a large volume

of high-pressure air or gas downstream of the

blower, a check valve in the piping downstream of

the blower will protect the blower from overspeeding

in a backward direction upon shutdown.

Consult a Tuthill Vacuum & Blower Systems sales

professional if questions arise.

DESCRIPTION

04

Loading...

Loading...