Manual 2007 Rev B p/n 2007

20

05

Installation

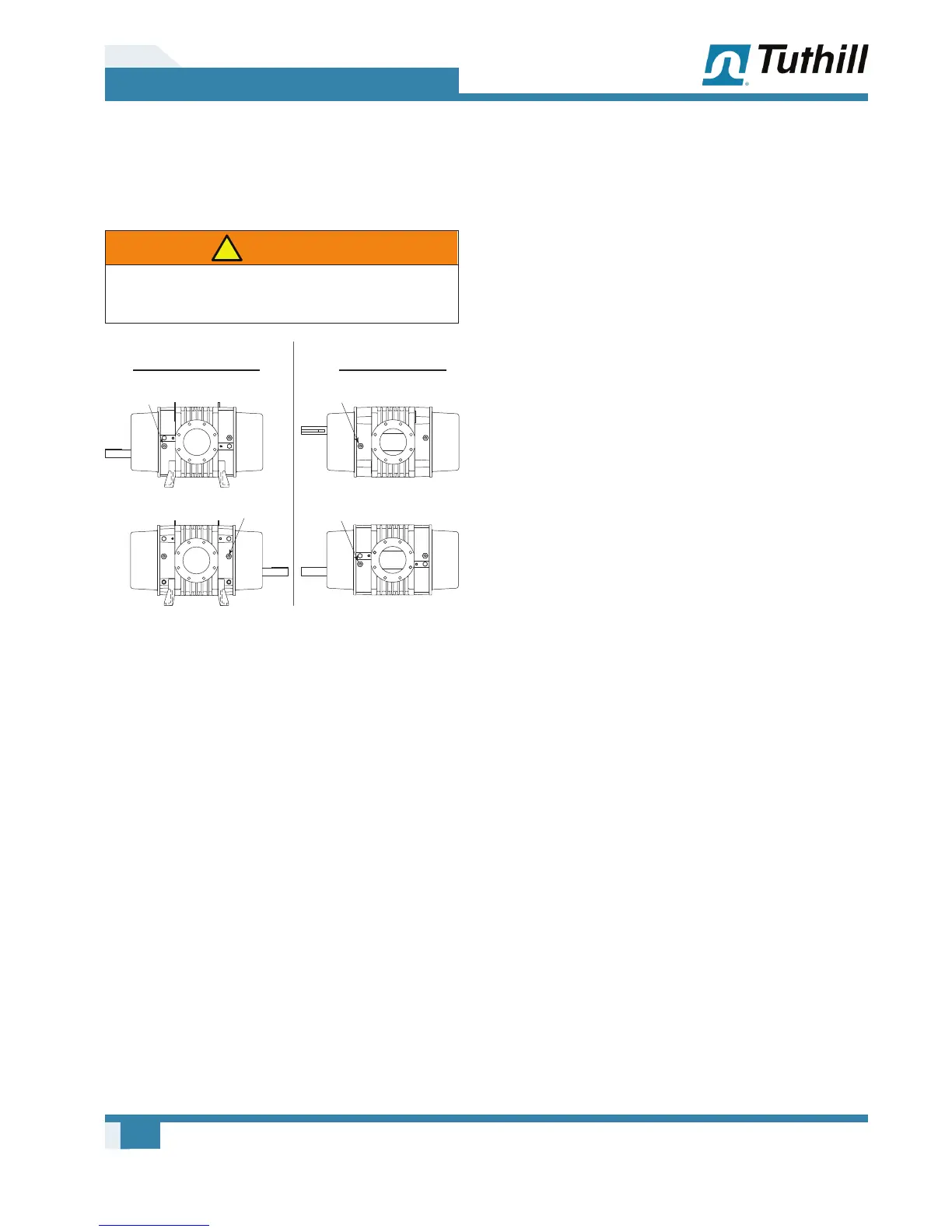

COOLING WATER CONNECTIONS

AND SPECIFICATIONS — COOLING

COILS (OPTIONAL)

WARNING

!

The cooling water pressure shall not exceed

75 psig (5.17 bar g).

PD 7000 SERIES

HORIZONTAL FLOW

PD 7000 SERIES

VERTICAL FLOW

1/2 NPT

WATER OUTLET

(1) EA END PLATE

1/2 NPT

WATER OUTLET

(1) EA END PLATE

1/2 NPT

WATER IN

(1) EA END PLATE

1/2 NPT

WATER INLET

(1) EA END PLATE

Figure 5-6 – Cooling Connections on Blowers with

Cooling Coils Option

MOTOR DRIVES

Two drive connections commonly used are direct

drive and V-belt drive.

Direct Coupled

When installing the motor directly to the blower,

align the shafts to the coupling according to the

coupling manufacturer’s instructions. Blowers

shipped with motor directly coupled and mounted

on a common base have been aligned prior to

shipment. Further alignment is normally necessary,

but be sure to check the alignment and make

adjustments if necessary prior to starting the

blower.

Coupling halves must correctly fi t the blower and

drive shafts so that only light tapping is required to

install each half. The two shafts must be accurately

aligned, A direct-coupled blower and motor must be

aligned with the two shafts not having more than

0.005 in. (13 mm) Total Indicator Reading (T.I.R.).

Make sure the face is aligned within 0.002 in.

(0.05 mm).

Establish proper gap between coupling halves

according to the coupling manufacturer’s

instructions with the motor armature. Proper

gap will minimize the chance for end thrust

on the blower shaft. Re-align and grease all

direct-coupled base-mounted blowers after fi eld

installation.

V-Belts

If the motor and blower are V-belt connected, the

sheaves on both the motor and blower shafts

should be as close to the shaft bearings as

possible. Blower sheave is not more than 1/4 in.

(6.5 mm) from the blower drive end cover. The

drive sheave is as close to the driver bearing as

possible. Take care should when installing sheaves

on the blower and motor shafts. Make sure the

face is accurately in line to minimize belt wear.

Adjust the belt tension to the to the manufacturer’s

specifi cations using a belt tension tester. Check

new belts for proper tension after 24 hours of run

time. When manufacturer data is not available,

industry guidelines are 1/64 in. defl ection for each

inch of span (0.157 mm per centimeter of span) at

8 – 10 lb (3.6 – 4.5 kg) of force in the center of the

belt.

Insuffi cient tensioning is often indicated by slipping

(squealing) at start-up. Do not use belt dressing

on V-belts. Keep sheaves and V-belts free of oil

and grease. Remove tension from belts if the

drive is to be inactive for an extended period of

time. For more specifi c information, consult the

drive manufacturer. In a V-belt drive, the blower

sheave must fi t its shaft accurately, run true, and

be mounted as close to the bearing housing as

possible to minimize bearing loads.

Loading...

Loading...