Manual 2007 Rev B p/n 2007

21

05

Installation

A tight or driving fi t will force the drive shaft out of

its normal position and cause internal damage. A

loose fi t will result in shaft damage or breaking.

Make sure the motor sheave fi ts correctly and is

properly aligned with the blower sheave.

Adjust the motor position on its sliding base so

that belt tension is in accordance with the drive

manufacturer’s instructions. Always avoid excessive

belt tension. Recheck tension after the fi rst 10

hours of operation and periodically thereafter to

avoid slippage and loss of blower speed.

Check blower after installation and before applying

power by rotating the drive shaft by hand.

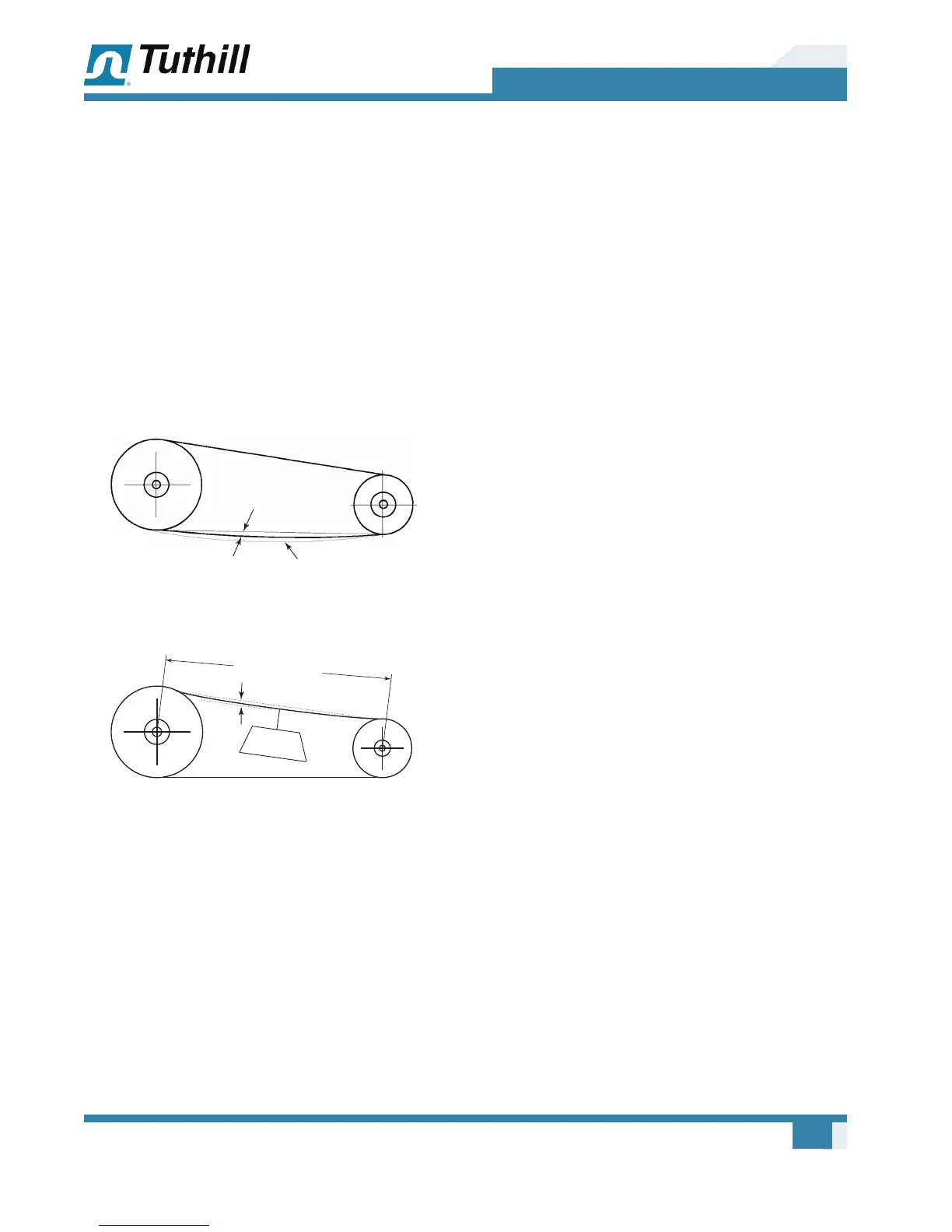

Too Tight

Slight Bow

Too Loose

Figure 5-7 – General appearance of a V-belt drive

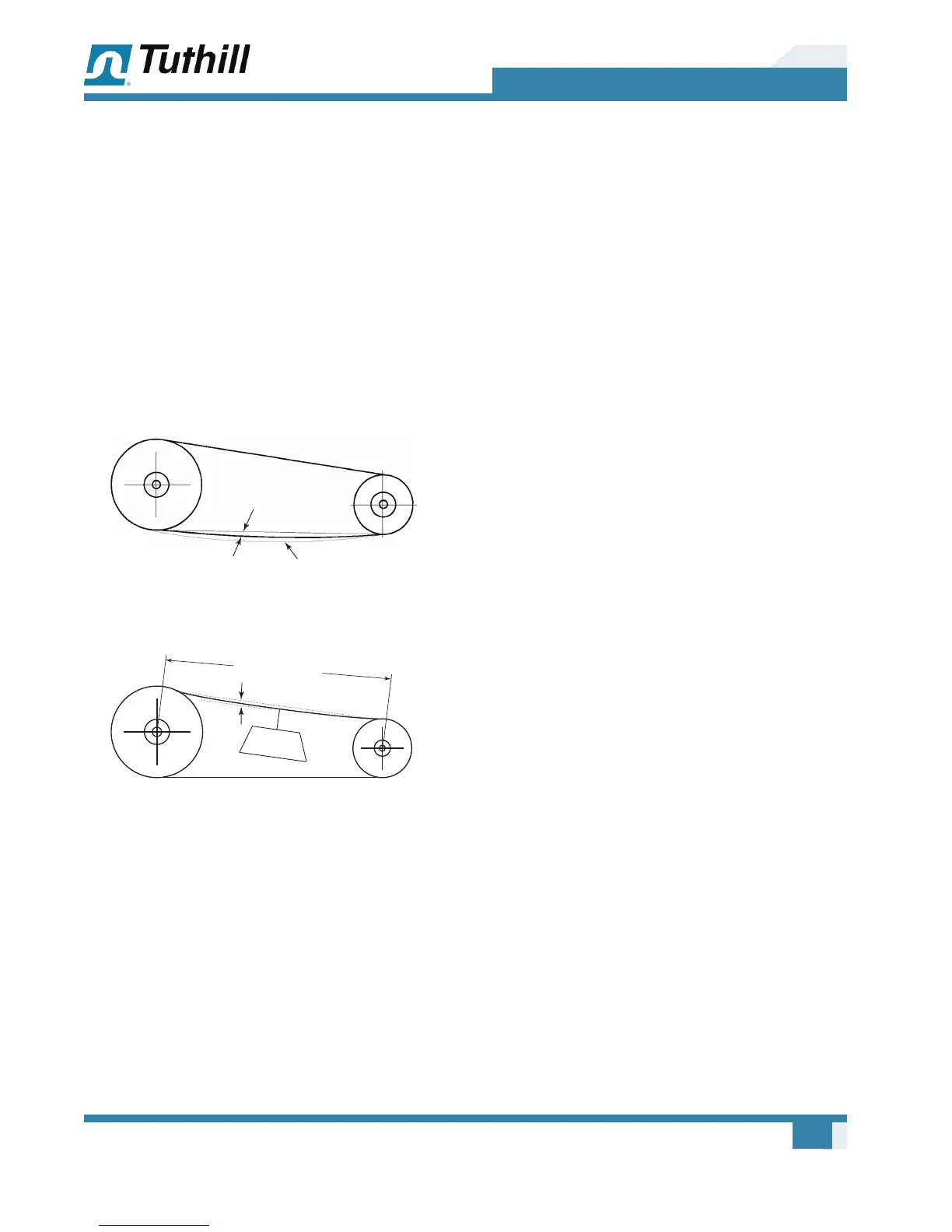

20/64” = 5/16” (8 mm)

20”

(50.8 cm)

8-10 lbs.

(3.6-4.5 kg)

Figure 5-8 – Setting of proper tension for a V-belt drive

Check the blower after installation and before

applying power by rotating the drive shaft by hand.

If the drive shaft does not rotate freely:

• Look for uneven mounting, piping strain,

excessive belt tension, or coupling misalignment.

• Check the blower to make sure oil was added to

the reservoirs.

Setting V-Belt Tension

Proper belt tension is essential to long blower

life. Figure 5-7, Figure 5-8, and the following

procedure are provided to aid in fi eld-adjusting

V-belts (when the blower is so equipped) for

maximum performance. A visual inspection of the

V-belt drive should yield the appearance shown in

Figure 5-7.

Factors outside the control of the belt tensioning

system used on an individual blower package

assembly, such as environmental factors and

quality of the belts installed, may contribute to

decreased belt life. Such factors can cause wear

of the belts beyond the ability of the tensioning

system to compensate.

As such, it is recommended to check belt tension

monthly and make any manual adjustments found

necessary.

1. Turn off and lock out power.

2. Remove the fasteners from the belt guard (if

equipped).

3. Remove the belt guard.

4. Check and adjust the belt tension as

necessary. Tension should be 1/64 in.

defl ection per inch of span (0.157 mm

defl ection per centimeter of span) between

sheaves, with 8 – 10 lb (3.6 – 4.5 kg) force

applied at the center point of the top section of

the belt.

5. Install the belt guard, making sure that all drive

components are free of contact with the guard.

6. Install the belt guard fasteners that were

removed in step 2.

7. Unlock the power and start the blower.

8. Resume normal operation.

Loading...

Loading...