Manual 2007 Rev B p/n 2007

26

06

Operation

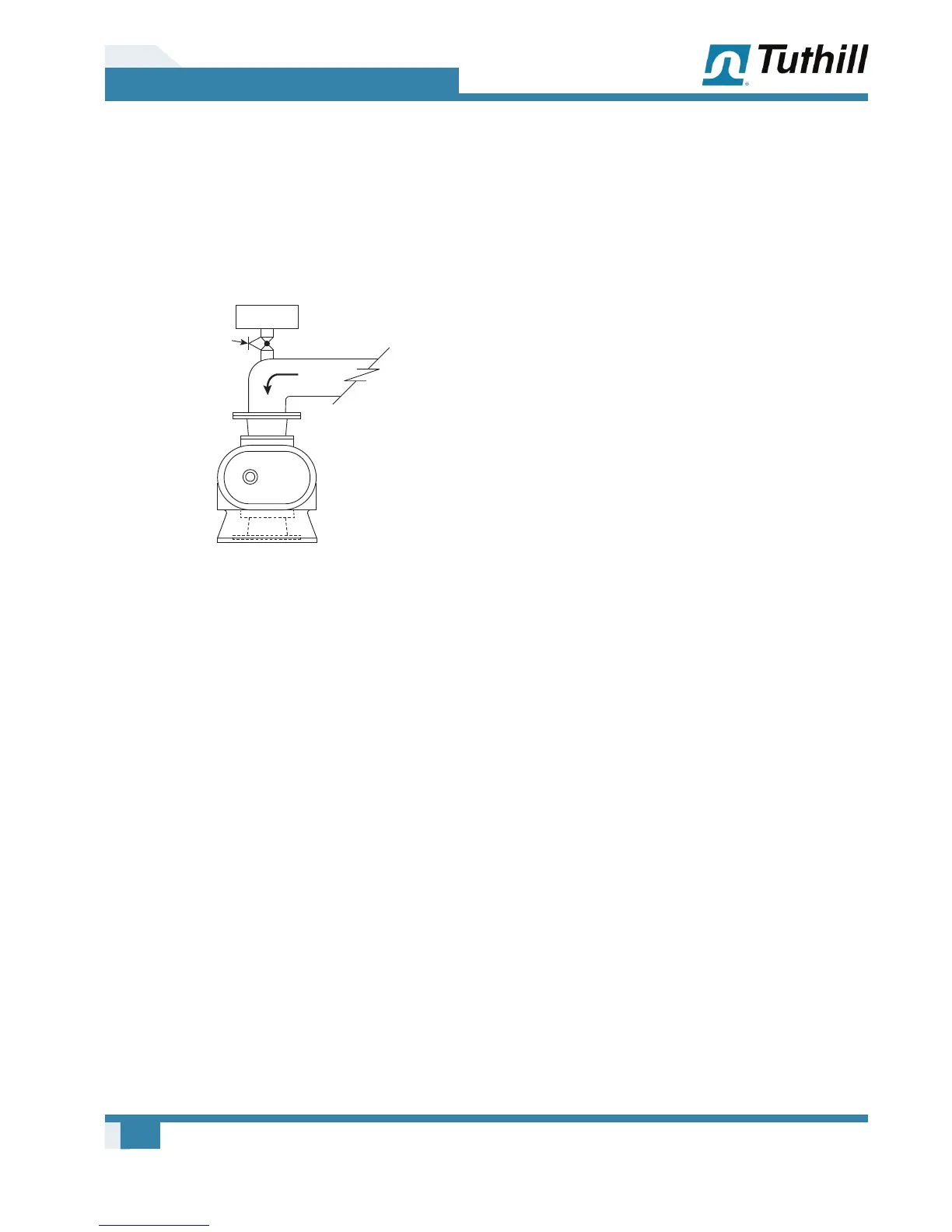

Inject the mixture on the inlet side through a valve

set to feed 1 gal (3.8 L) of mixture in 15 – 20

minutes. On blowers that are regularly fl ushed,

fl ushing once a week is suffi cient. If the blower is

dirty, fl ush it daily until the hard build-up is removed

and then move to a weekly cycle. In very dirty gas

installations, vary the cycle to meet the demand.

FLUSHING

FLUID

CONTROL

VALVE

Figure 1-1 – Flushing

WATER-INJECTED BLOWERS

Water injected into the inlet of a blower operating

on vacuum service will cool the blower. The water

absorbs the heat of compression as it passes

through the blower along with the air/gas being

compressed. A blower cooled in this manner can

operate safely at higher vacuums or higher inlet

temperatures than an uncooled blower.

The amount of water required depends on the

inlet air/gas temperature, inlet vacuum, water

temperature, and maximum discharge temperature

desired. Check with the factory or sales

representative for more guidance.

Operation

1. Check the oil level in the sight glass of the

blower and make sure all fi ttings are tight.

2. Check the water injection system to make sure

water is available.

3. Operate the blower dry for 3 minutes at no

load to check for correct rotation and smooth

operation.

4. Turn the water on and adjust fl ow as

recommended for the individual blower. Make

sure the water discharges freely from the outlet

piping.

5. Apply vacuum and observe operation at the

desired inlet condition.

Shutdown

It is possible to shut down the blower for brief

periods by relieving the inlet vacuum, shutting off

the water, and then stopping the blower.

To avoid rusting during a slightly longer shutdown

period, operate the blower under a partial vacuum

without the water injection, allowing the blower to

heat within safe limits. The heat will tend to drive

off residual moisture.

For extended shutdown, oil may be injected into

the inlet of the heated blower just prior to shutting

down the blower. The oil will provide a protective

coating on the internal components. Make sure the

water is completely shut off after shutdown.

Special coatings or platings are available to

minimize rusting or corrosion in applications where

blowers can remain wet.

Always use vertical-fl ow blowers with two-lobed,

plugged rotors. Always orient system with the

blower intake at the top and discharge at the

bottom.

Loading...

Loading...