Manual 2007 Rev B p/n 2007

18

05

Installation

Lubrication (Integral Pressure)

Before starting the blower, fi ll the oil reservoirs as

follows:

1. Remove the oil fi ll plug.

2. Pour oil through the fi ll hole until oil appears in

the sight glass.

OTE: N The front and back oil reservoirs are

connected. However, it may take a few

minutes for the oil to travel to the front of

the blower.

3. Bring the oil level up to the center of the sight

glass.

OTE: N Again, allow time for the oil level to

equalize between the front and back of

the blower.

4. Reinstall the fi ll plug.

Oil Filter on Integral Lube Blowers

Change the oil fi lter element at every oil change.

The oil fi lters (P/N 70248) are available from

Tuthill Vacuum and Blower Systems in Springfi eld,

Missouri, or from any authorized distributor or

service center.

Integral Lube Oil Pressure Adjustment

The oil pressure on each blower has been preset

at the factory during the load testing. The oil

pressure should not require adjustment once the

blower is installed and in operation. However, in

rare cases, some adjustment may be needed due

to speed and oil temperature.

Once the blower reaches operating temperature,

the oil pressure can be adjusted to the proper

range. The oil pressure should be set to 15 psig

(103 kPa).

To adjust the blower to the proper oil pressure:

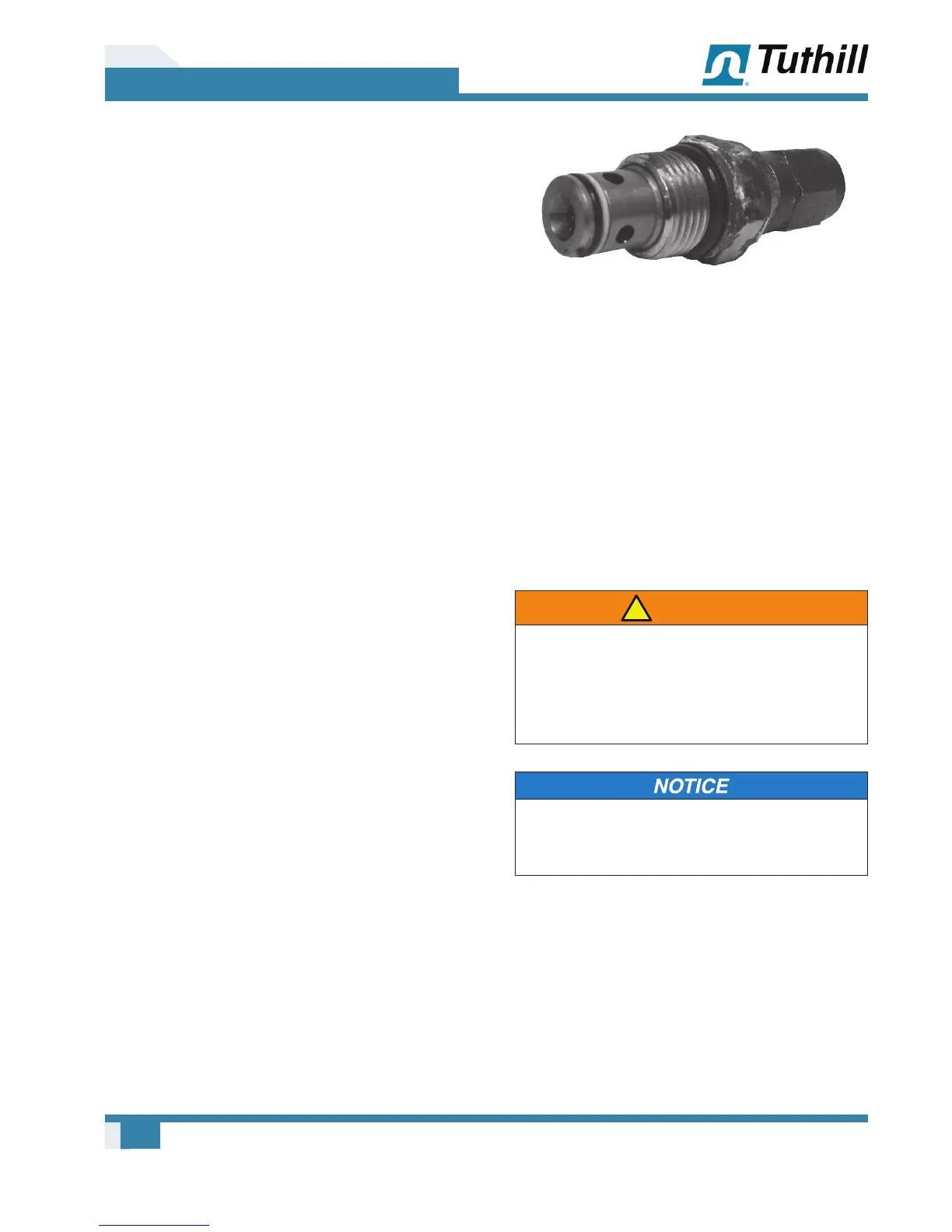

1. Remove the hex cap (see Figure 5-5).

Figure 5-5 – Oil Pressure Adjustment Hex Cap

2. Loosen the lock nut.

3. Turn the set screw clockwise to increase the

pressure or counterclockwise to decrease the

pressure.

4. Tighten the lock nut and replace the cap.

5. Read the oil pressure. Repeat the process to

re-adjust the pressure if necessary.

PIPING CONNECTIONS

WARNING

!

Pipe loading on the blower should be

negligible as pipe loading can cause

distortion of the blower. Use proper supports

and pipe hangers to assure that there is no

loading.

Remove the protective covers from the inlet

and outlet ports and inspect for dirt and foreign

material.

Inlet and outlet connections on all blowers are

large enough to handle maximum volume with

minimum friction loss. Maintain same-diameter

piping. Do not support silencers by the blower.

Avoid stress loads and bending moments.

Be certain all piping is clean internally before

connecting to the blower. Place a 16-mesh wire

screen backed with hardware cloth at or near

the inlet connections for the fi rst 50 hours of use

until the system is clean. Clean the screen after

Loading...

Loading...