Manual 2007 Rev B p/n 2007

34

08

Disassembly and Reassembly

Drive

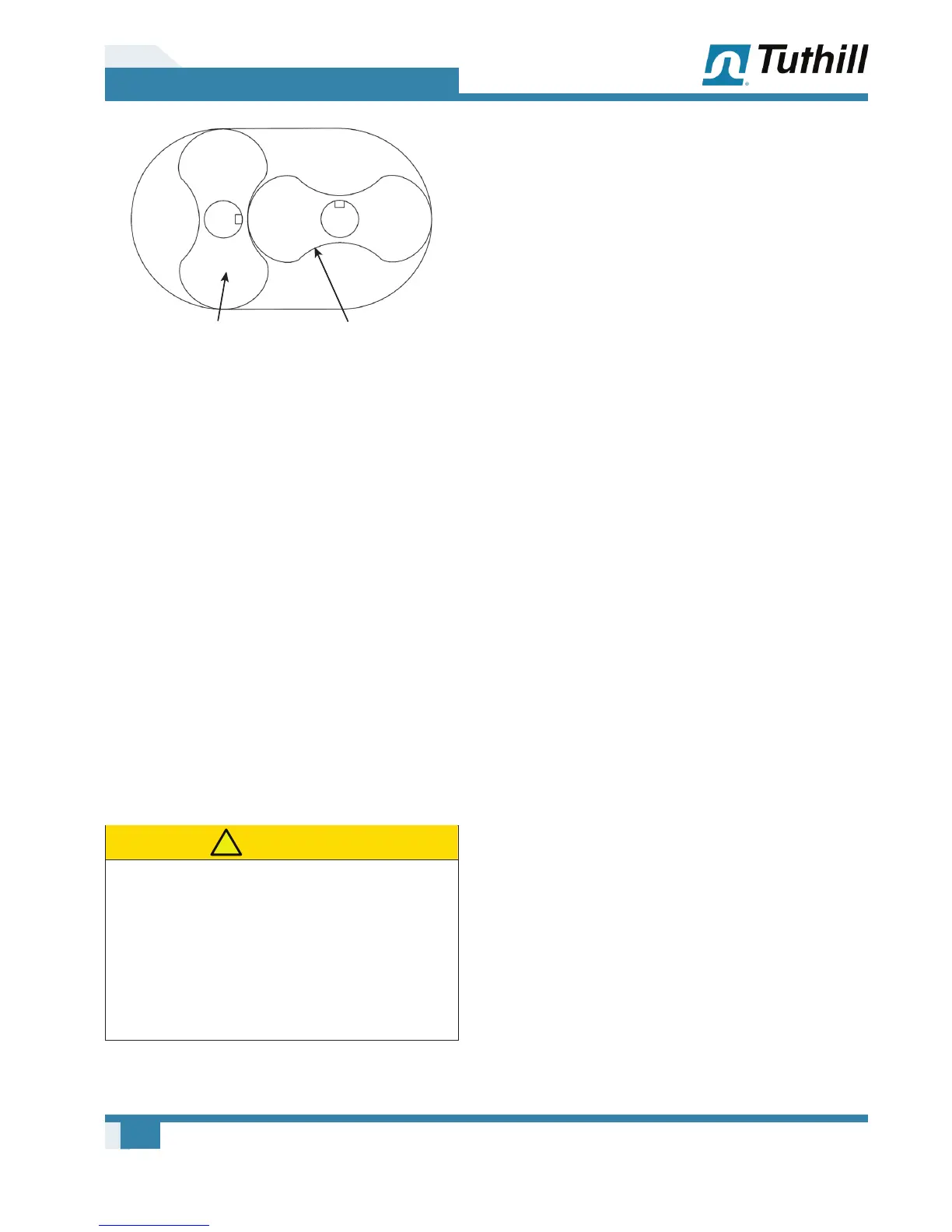

Driven

DRIVE DRIVEN

Figure 8-3 – Keyways

4. Install the gear end plate over the rotor

shafts and coming to rest on top of the rotor

lobes, being careful not to damage the seals.

Recheck the location of the oil sight glass in

relation to the drive rotor before proceeding

with the assembly.

Lab seals series only: Skip step 5. Proceed

to step 6.

5. Mechanical face seal series only: Inspect

the lapped surface of the seal mating ring to be

sure it is perfectly clean. Use a soft tissue and

cleaning agent if necessary. Place a few drops

of lubricating oil on its surface and lubricate the

O-ring. Install on the rotor shaft with the lapped

surface down. The slot must line up with the

pin in the rotor shaft. Gently press with fi ngers

to ensure compression is taking place and the

mating ring is not hung up for any reason. The

top of the mating ring should sit fl ush with the

rotor shoulder when fully seated.

CAUTION

!

Gear end bearings have fl ush ground faces

and should be installed with manufacturer

numbers up (toward gear). If no numbers

appear on either side, look for a black dot

(acid mark) on the inner race. Install with dot

up (toward gear). Do not use bearings that

have not been fl ush ground to within a .001"

(.025 mm) tolerance.

6. Coat the rotor shafts with an anti-seize

lubricant and press the bearings on the shafts.

The bearing manufacturer numbers and/or an

acid dot (inner race) should be up or toward

the gears. Use the tool shown in Figure 13-4

along with a length of 3/4”-10 × 6 in. threaded

rod, washer, and nut. Tuthill recommends the

use of a hydraulic ram with a hollow center, in

which case the threaded rod will have to be

made longer. Install the bearing retainer plates

and secure with cap screws.

7. Check the clearance between the face of the

end plate and rotor lobes. See Assembly

Clearances on page 39 for the correct

gear end clearances. If clearances are not

within specifi cations, recheck the parts to fi nd

the cause of the improper clearances before

proceeding. Install the keys in the rotor shaft

keyways.

8. Lubricate the shafts and keys, and press the

drive gear (right-hand helix) on the drive rotor.

To install the driven gear, align the reference

marks as shown in Figure 8-5. Tap the gear

with a mallet to start, and then press the gear

until seated.

OTE: N All timing gears must be used in sets as

they are matched and serially numbered.

9. Install the roll pins, washers, lock tabs, and

shaft bolts. Bend over the lock tabs.

OTE: N These bolts are structural bolts, not

standard cap screws. Therefore they have

a larger body diameter and this centers

the washers and slinger. Do not replace

with standard cap screws.

10. Remove the gear end assembly from the free

end plate, and turn over so the gears are

facing down on some wood blocking on each

side for support.

11. Mechanical face seal series: Place a small

bead of sealant around the periphery of the

housing bores but inside the bolt pattern.

Encircle the dowel pins. Install the rotor

housing and temporarily secure it to the end

plate with two cap screws and some fl at

washers. Check the clearances between the

end of the lobes and housing using a fl at bar

and feeler gauges or a depth micrometer. See

the exploded view for free end clearances.

Loading...

Loading...