4. Stopping the engine and the Tractor

(1) Decrease the throttle opening and depress clutch pedal. When necessary, depress also the brake

pedal, thus halting the tractor.

(2) Put the shifting levers to the neutral position, release the clutch pedal and lock the brake pedal if

necessary.

(3) Idling the engine for something until the water temperature drops to below 70°C, then pulling the

shut-off pull rod to stop the engine. It is strictly forbidden to stop the engine suddenly from high

temperature.

26

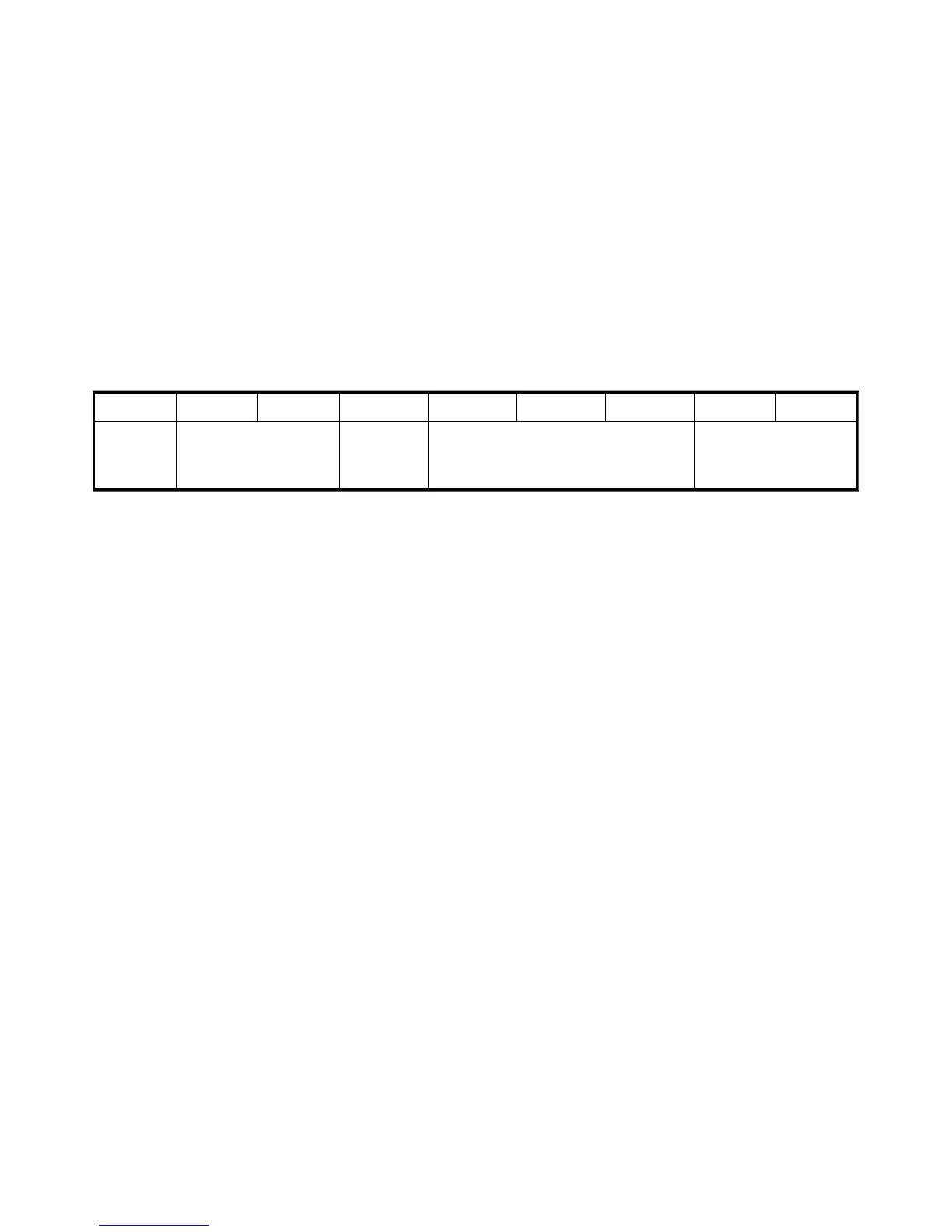

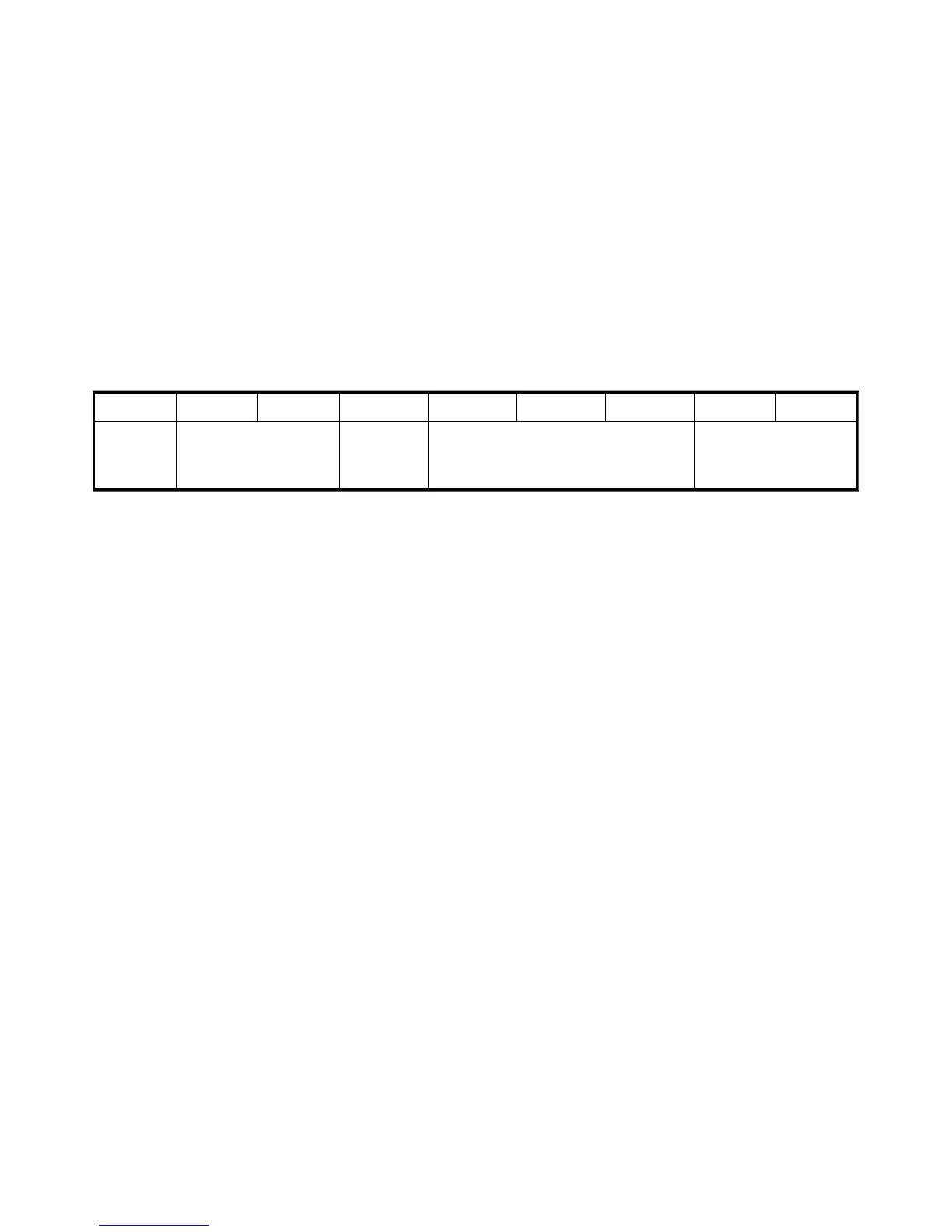

gear 1st 2nd 3rd 4th 5th 6th 7th 8th

Rotary tillage,

Transplantation

Plowing, harrowing and seeding Transportation

Usage

Harvesting

Table 4-1 Usage of various speeds of tractor

4.3 Operation of the Working facilities

1. Operation and Control of the PTO Shaft (see Fig.4-3)

(1) Put the control lever of the PTO shaft at neutral position. Remove the PTO shaft guard and connect

reliably the PTO shaft to the implement.

(2) Depress the clutch pedal. Depending on the requirement of the implement the control lever of the

PTO shaft is set at the high or low position

(3) Gradually release the clutch pedal to start the implement. First run the implement at low speed to

inspect the the operation condition. If it runs normally, it will be put to work in the normal condition.

2. The Operation and Control of the Hydraulic Lift System (see Fig 5-12, 5-13)

(1) The main technical specifications of hydraulic lift system

Type : Partial separated units

Working depth control :Position control, draft and position combined control, float control

Type of pumping :CB310(right-handed)(ET 350 ECONO)

CB310(left-handed)(ET 350 ECONO)

Displacement of oil pump(mL/r) :10;14

Change over valve :Two-position, Y-way sliding type

Loading...

Loading...