A

B

a

b

A

IncreaseIncrease

DecreaseDecrease

Screw

-6-

12

13

14

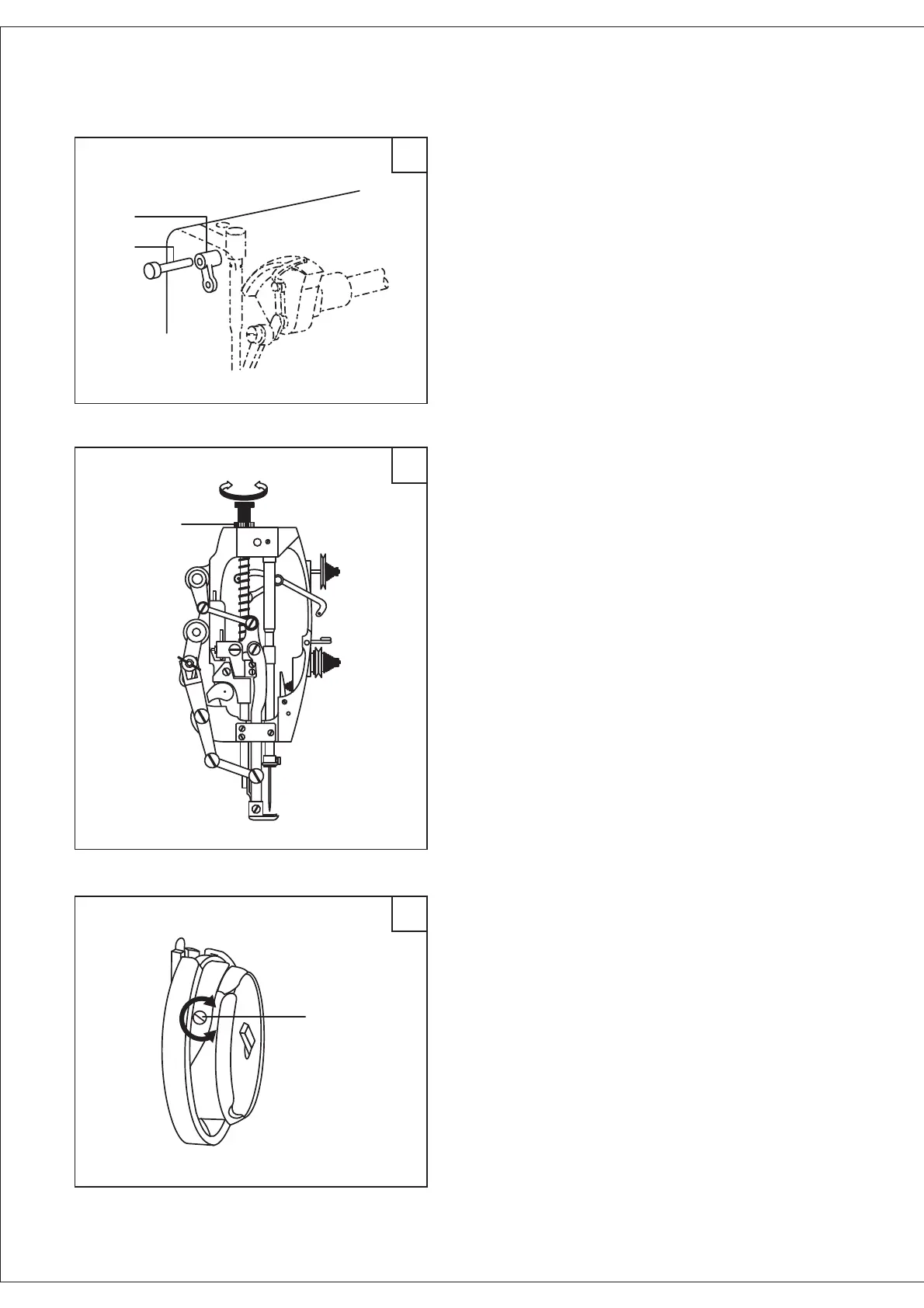

Thread take-up parts adopt woolen thread oiling.

After a long time using, its function lost. So it must

be replaced with a new one. Steps as below:

Thread take-up parts adopt woolen thread oiling.

After a long time using, its function lost. So it must

be replaced with a new one. Steps as below:

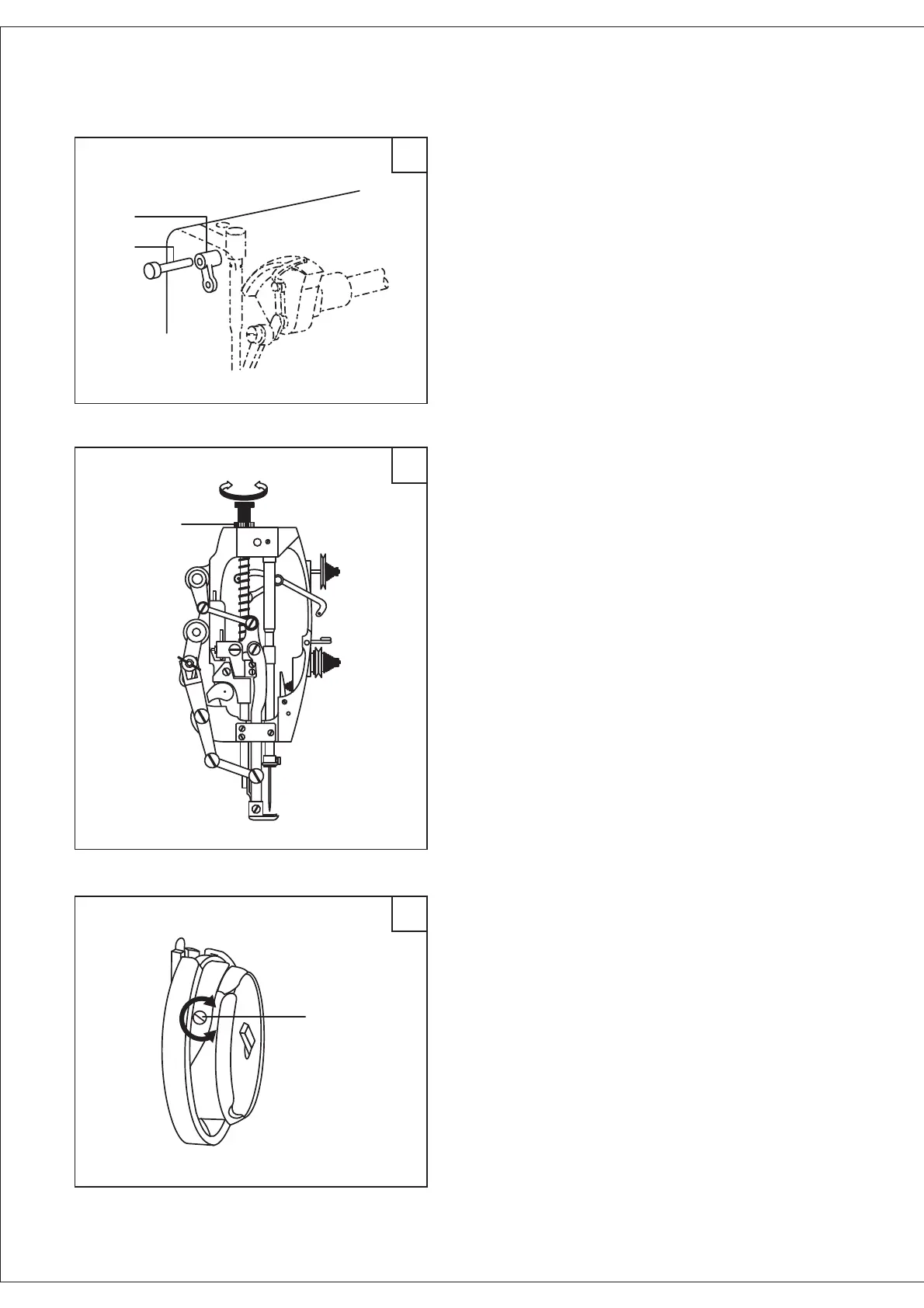

Pressur on presser foot is to be adjusted in

accordance with materials to be sewn. Loosen the

locknut (A). If heavy materials to be sewn, turn the

presser regulation thumbscrew clockwise as shown in

Fig (a) to increase the pressure. While light materials

to be sewn, turn the pressure regulating thumbscrew

counter clockwise as show in Fig. (b) to decrease the

presser on presser foot. Then tighten the lock nut (A).

The pressure on presser foot is proper as the

materials can be fed normally.

e

.

Pressur on presser foot is to be adjusted in

accordance with materials to be sewn. Loosen the

locknut (A). If heavy materials to be sewn, turn the

presser regulation thumbscrew clockwise as shown in

Fig (a) to increase the pressure. While light materials

to be sewn, turn the pressure regulating thumbscrew

counter clockwise as show in Fig. (b) to decrease the

presser on presser foot. Then tighten the lock nut (A).

The pressure on presser foot is proper as the

materials can be fed normally. .

e

The tension on thread can be adjusted according

to the materials and different types of thread.

Normally, adjust the thread tension according to the

sewing stitches. Adjust the sewing stitches by

changing the tension on bobbin thread and needle

thread.

Increase or decrease the bobbin thread tension by

using the small screwdriver to turn the screw on

bobbin case.

Depend on the tension on bobbin case, by changing

the take-up spring tension & range, the tension of

tension spring, the position of tension disc and

thread finger to adjust the needle thread tension.

.

.

.

The tension on thread can be adjusted according

to the materials and different types of thread.

Normally, adjust the thread tension according to the

sewing stitches. Adjust the sewing stitches by

changing the tension on bobbin thread and needle

thread. .

Increase or decrease the bobbin thread tension by

using the small screwdriver to turn the screw on

bobbin case.

Depend on the tension on bobbin case, by changing

the take-up spring tension & range, the tension of

tension spring, the position of tension disc and

thread finger to adjust the needle thread tension. .

.

(1) Open the faceplate remove the pressure screw,

lock nut and adjusting bar.

(2) Remove the pin (A) and draw out the old oil

wick.

(3) Draw out the oil wick in the part (B).

(4) Change the new oil wicks.

(5) Installing is a reverse sequence.

(1) Open the faceplate remove the pressure screw,

lock nut and adjusting bar.

(2) Remove the pin (A) and draw out the old oil

wick.

(3) Draw out the oil wick in the part (B).

(4) Change the new oil wicks.

(5) Installing is a reverse sequence.

16. Oiling the thread take-up parts

(Fig. 12)

17. Adjusting the pressure of presser

foot (Fig. 13)

18. Installing the bobbin and adjusting

the thread tension (Fig. 14)

Loading...

Loading...