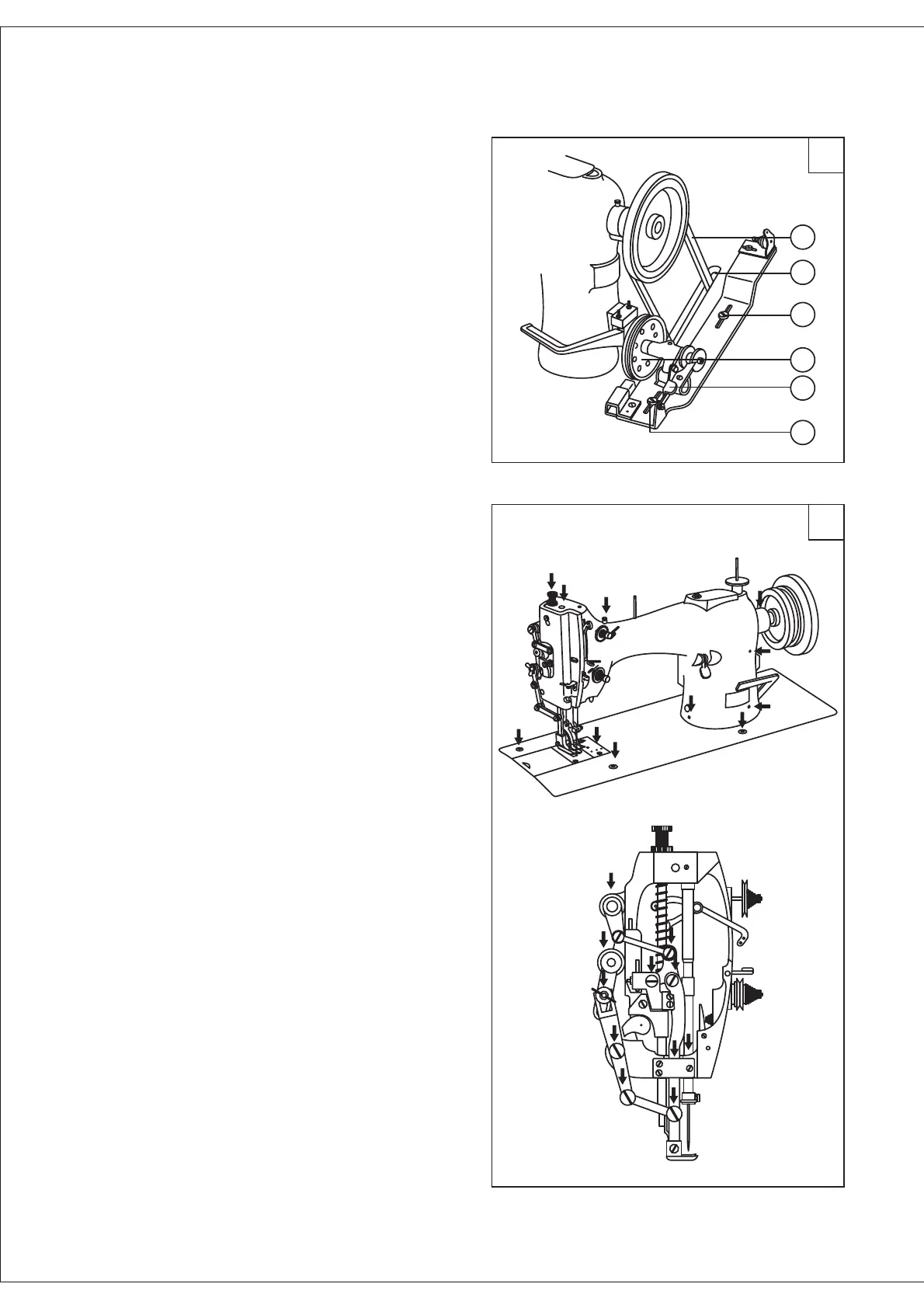

A

B

C

E

C

D

-3-

Align pulley (B) of the bobbin winder with the

outside of the belt (C). And there should be a proper

clearance between them so that the pulley can be

contacted with the belt when stop latch thumb lever

(A) is depressed. Thereby the belt drivers the pulley

(B) while the machine running, the bobbin winder

should be parallel with belt slit (E) of the table. Then

tighten the two wood screws. .

Align pulley (B) of the bobbin winder with the

outside of the belt (C). And there should be a proper

clearance between them so that the pulley can be

contacted with the belt when stop latch thumb lever

(A) is depressed. Thereby the belt drivers the pulley

(B) while the machine running, the bobbin winder

should be parallel with belt slit (E) of the table. Then

tighten the two wood screws. .

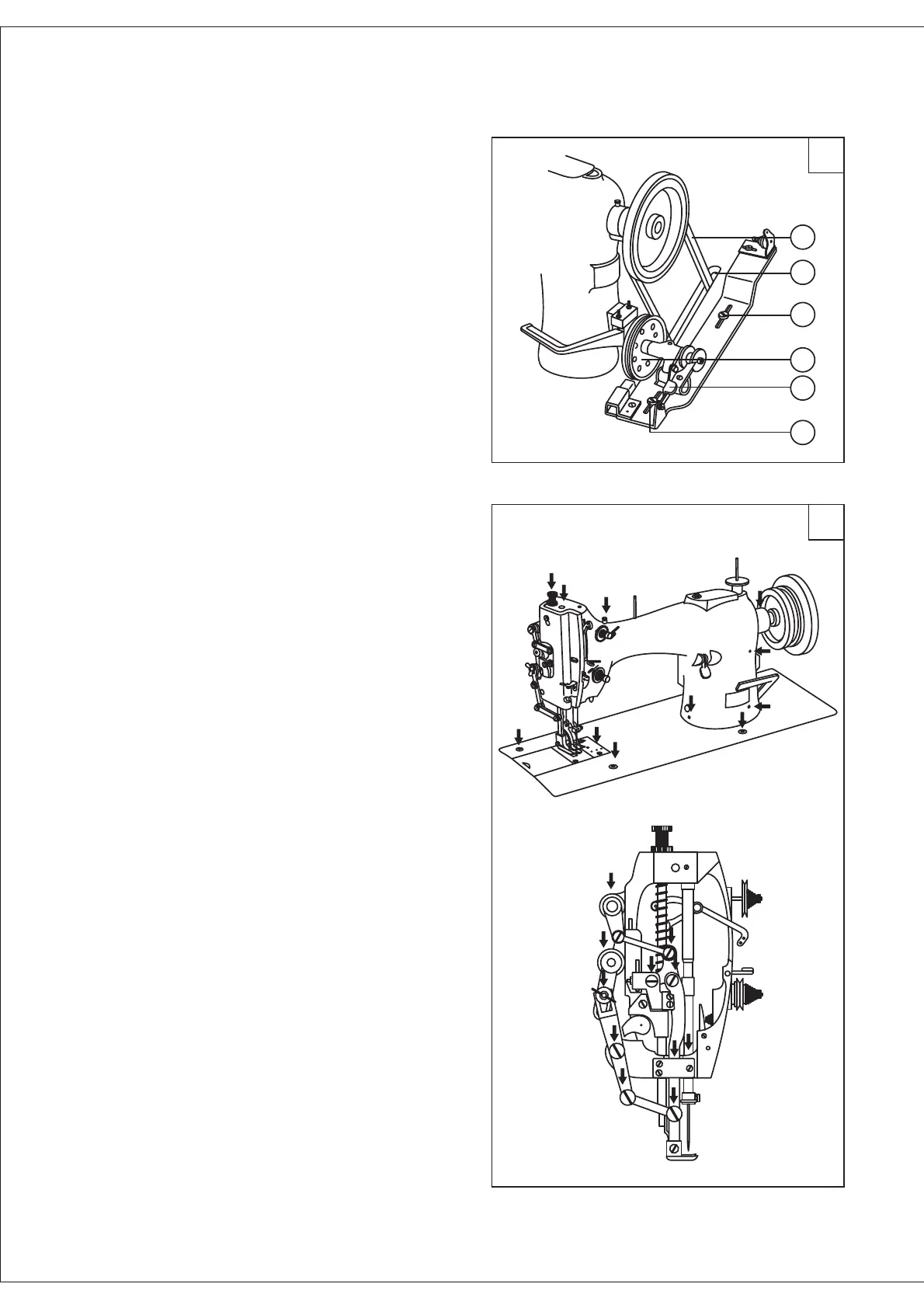

The places with red marks must be add

oil after the machine finish running daily. Then keep

running the machine for 1 2 minutes.

enough

.

The places with red marks must be add

oil after the machine finish running daily. Then keep

running the machine for 1 2 minutes. .

enough

8. Installing the bobbin winder (Fig. 5)

9. Lubrication (Fig. 6)

5

6

Loading...

Loading...