C

Ascending

Down

L

A

B

-11-

During the sewing, the center gauge (L) between

the walking foot sliding block and its shaft can be

adjusted according to the differences of the friction

coefficients of the friction coefficients of materials

and the sewing process. .

During the sewing, the center gauge (L) between

the walking foot sliding block and its shaft can be

adjusted according to the differences of the friction

coefficients of the friction coefficients of materials

and the sewing process. .

Method:

Increase L- the upper feed amount enlarged

Reduce L- the upper feed amount shortened

Method:

Increase L- the upper feed amount enlarged

Reduce L- the upper feed amount shortened

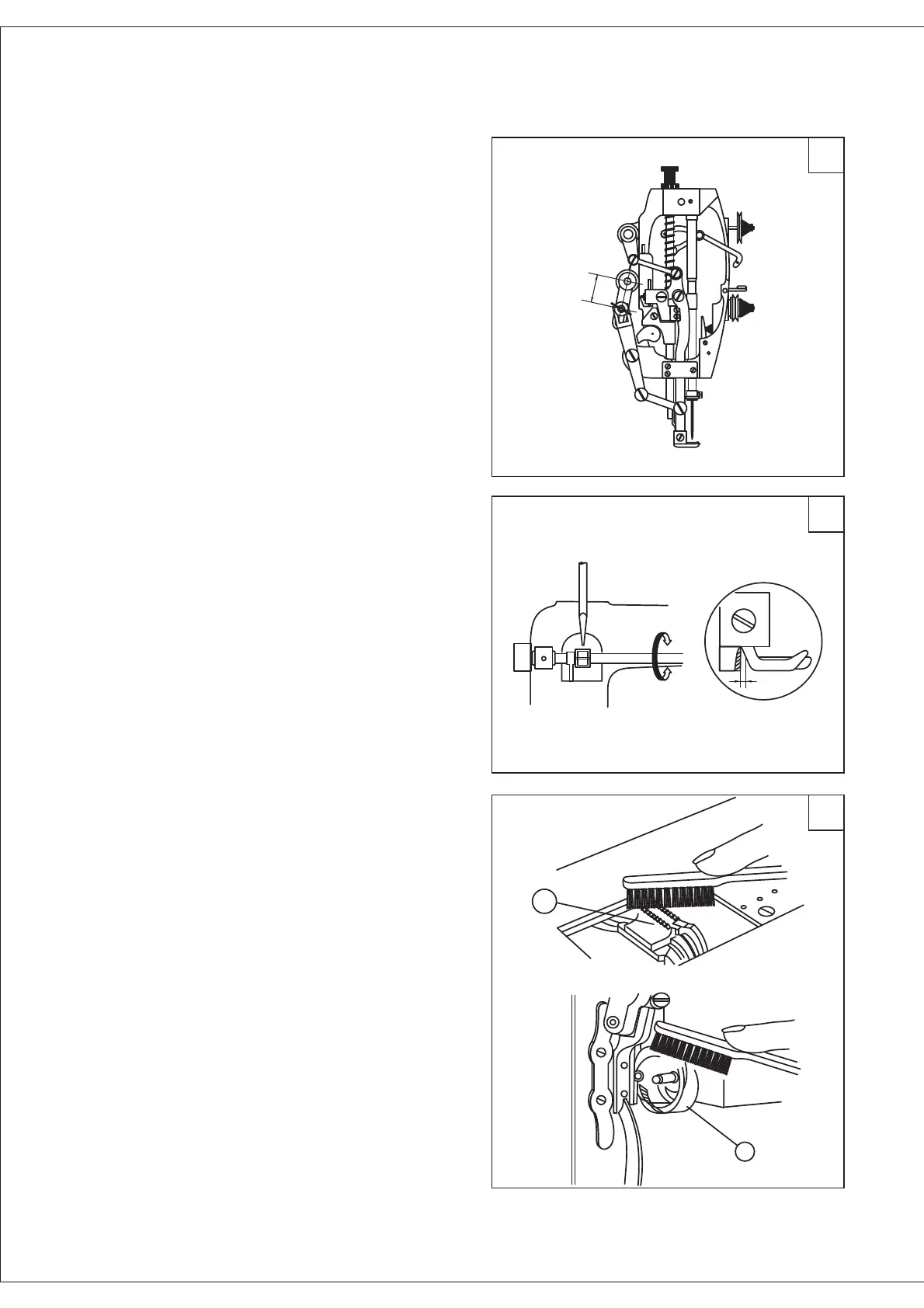

Clean the feed dog, the rotating hook and bobbin

case according to the machine use condition.

(1) Cleaning the feed dog

Remove the needle plate, clean off the dust and lint

in the slit of feed dog (A), then re-install the needle

plate.

(2) Cleaning the rotating hook

Clean off all the dust around the rotation hook (B)

and cleaning the bobbin case with soft cloth.

.

.

.

.

.

Clean the feed dog, the rotating hook and bobbin

case according to the machine use condition. .

(1) Cleaning the feed dog .

Remove the needle plate, clean off the dust and lint

in the slit of feed dog (A), then re-install the needle

plate. .

(2) Cleaning the rotating hook .

Clean off all the dust around the rotation hook (B)

and cleaning the bobbin case with soft cloth. .

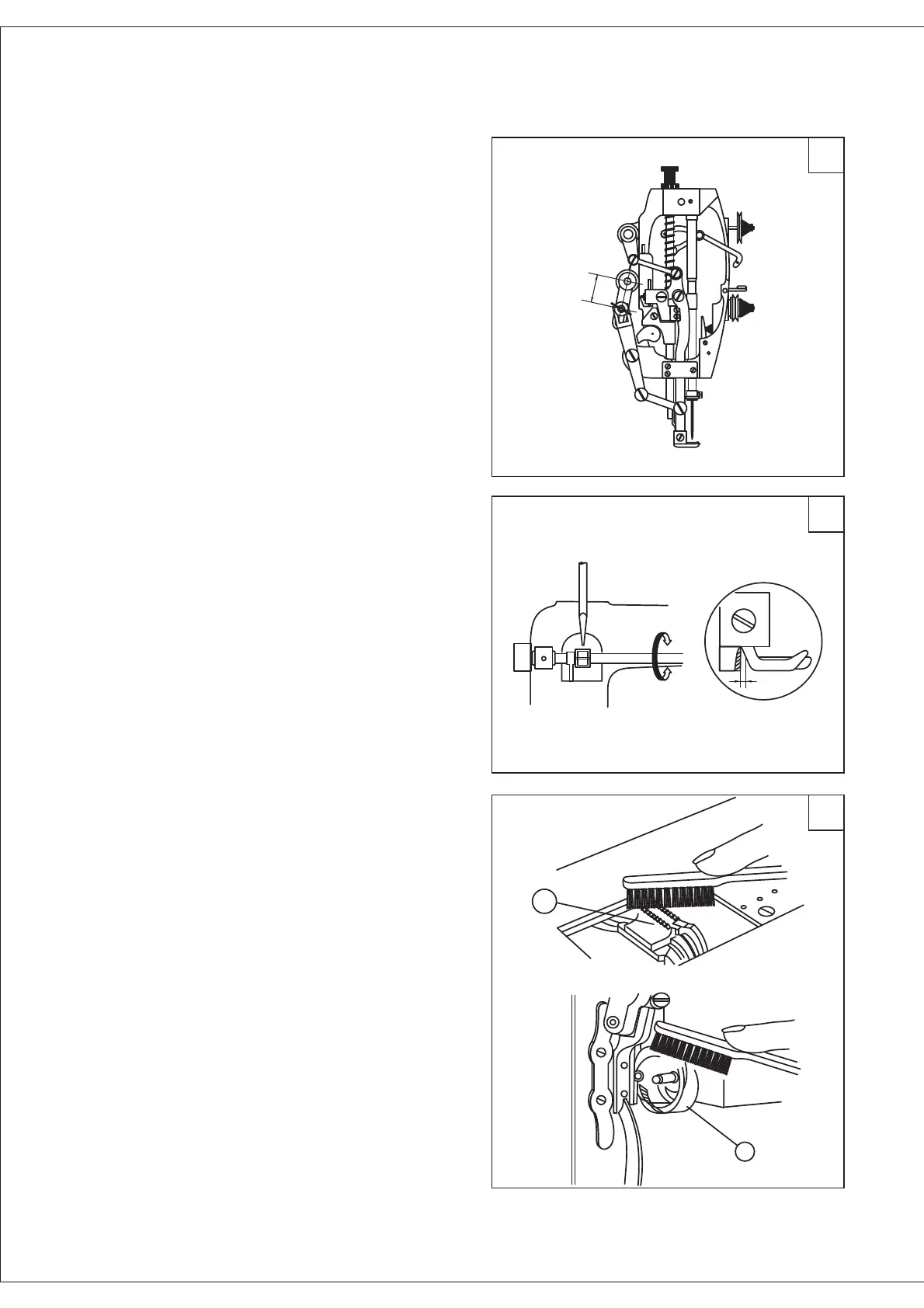

In sewing operation, for preventing the walking

foot from striking on the presser foot a proper

clearance (C) of approx. 1.5mm should be maintained

between them. When the clearance is too sm ll or too

big, it is necessary to adjust. Loose rear crank screw

and turn the rock shaft, then the walking foot moves

near the needle bar. When adjusting, be sure to note

the fixed number of the clearance (C).

a

.

In sewing operation, for preventing the walking

foot from striking on the presser foot a proper

clearance (C) of approx. 1.5mm should be maintained

between them. When the clearance is too sm ll or too

big, it is necessary to adjust. Loose rear crank screw

and turn the rock shaft, then the walking foot moves

near the needle bar. When adjusting, be sure to note

the fixed number of the clearance (C). .

a

For special sewing requirements, for example, the

upper layer of materials needs more amounts than the

low layer needs. In this case, adjustment can be done

in the range of above theory for operation. .

For special sewing requirements, for example, the

upper layer of materials needs more amounts than the

low layer needs. In this case, adjustment can be done

in the range of above theory for operation. .

26. Upper feed adjustment (Fig. 27)

28. Periodical cleaning (Fig. 29)

27. Adjusting the clearance between

presser foot and walking foot (Fig. 28)

5

5

6

Loading...

Loading...