-4-

7

8

When the machine left out of operation for a quite

long time and used again or a new complete machine,

remove the rubber plug and face plate on the top of

the machine head, oil it thoroughly. Then lift the

presser foot and run the machine at a low speed of

200 400 spm. After the machine is lubricated fully,

keep t ial running the machine for 30 minutes, and

then increase the speed gradually. After months

running to prefect its performance, then increase up

to its proper sewing speed.

r

.

When the machine left out of operation for a quite

long time and used again or a new complete machine,

remove the rubber plug and face plate on the top of

the machine head, oil it thoroughly. Then lift the

presser foot and run the machine at a low speed of

200 400 spm. After the machine is lubricated fully,

keep t ial running the machine for 30 minutes, and

then increase the speed gradually. After months

running to prefect its performance, then increase up

to its proper sewing speed. .

r

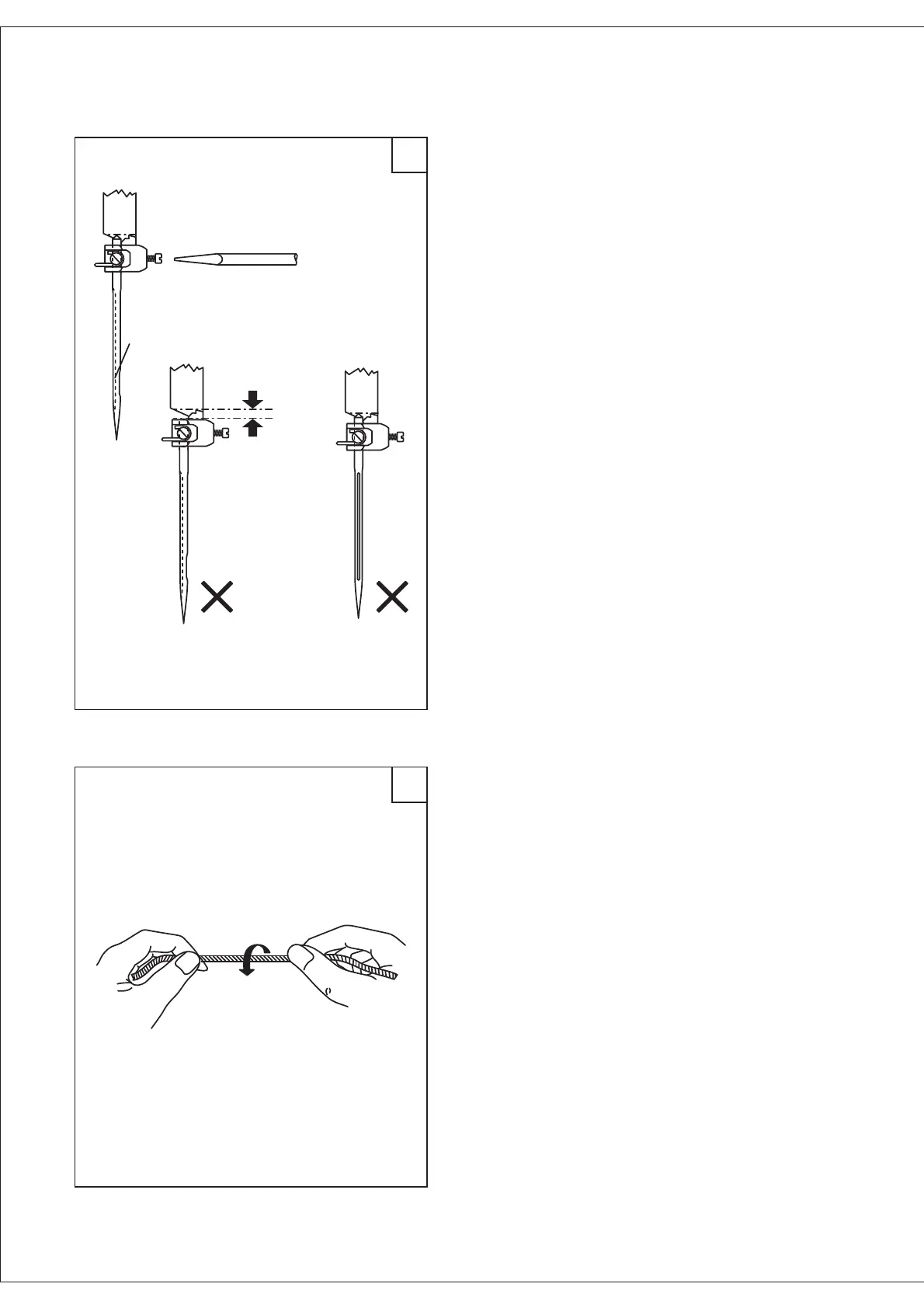

Turn the balance wheel to lift needle bar to its

highest position, loosen needle set screw (1), keeping

the long groves facing to the left side of operator, and

now fully insert the needle shank upto the bottom of

needle clamp. Last tighten the screw (1) to fix the

needle. .

Turn the balance wheel to lift needle bar to its

highest position, loosen needle set screw (1), keeping

the long groves facing to the left side of operator, and

now fully insert the needle shank upto the bottom of

needle clamp. Last tighten the screw (1) to fix the

needle. .

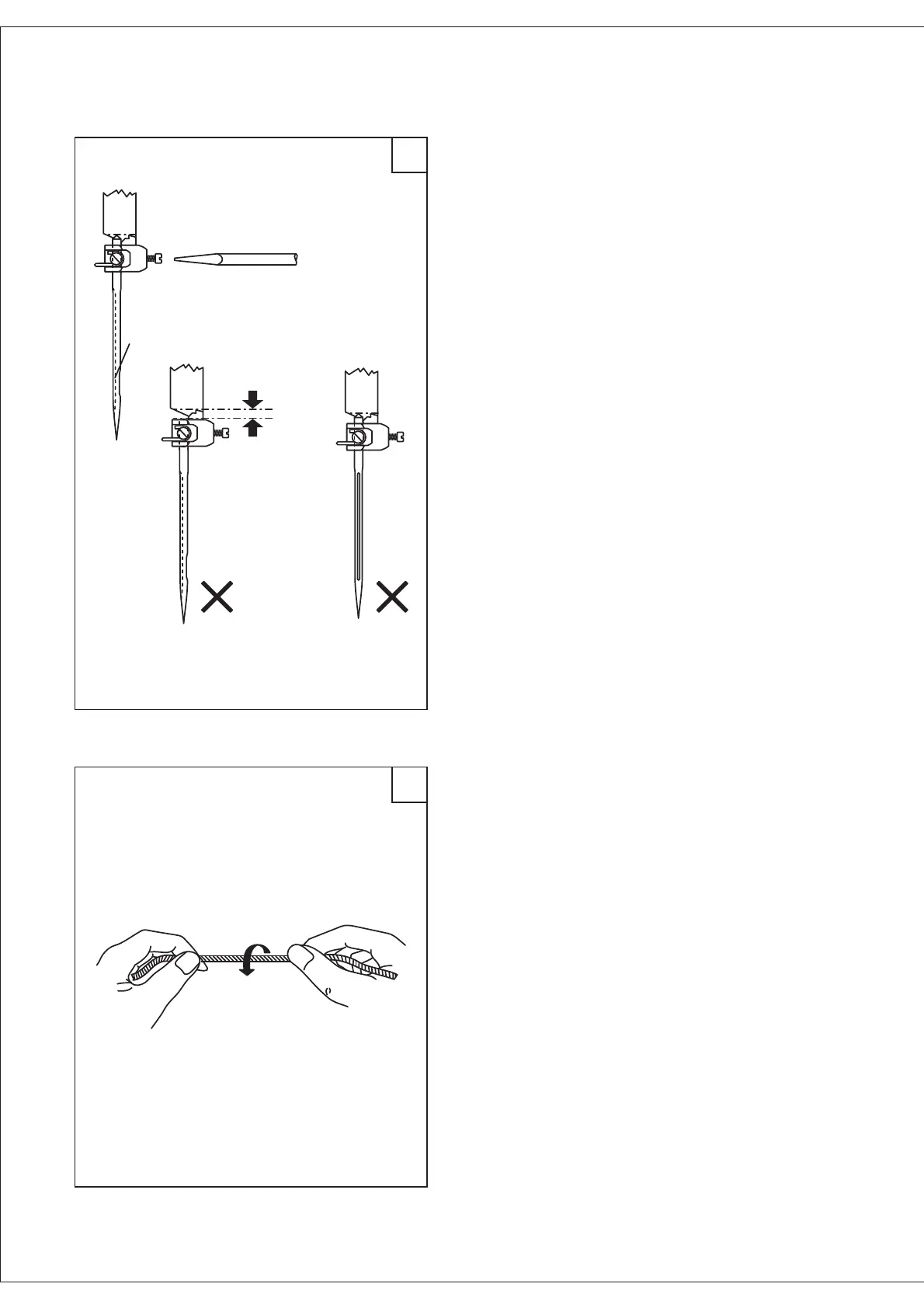

Please use the left-twisted needle thread and the

left-twisted or right-twisted bobbin thread. Shown as

Fig. 10, holding the thread, twist it with right hand in

the direction of arrow, if it becomes tight, it is

left-twisted thread. Otherwise, it is right-twisted

thread.

Please use the model DDX1 24# 27# needle.

The needle must be suitable for the materials. Sewing

too heavy-duty materials and using too thin needle,

the needle would be broken, thread skipping and

breaking. If the needle too heavy, it would damage

the fabric. So please choose the suitable needle

according to the materials.

.

.

Please use the left-twisted needle thread and the

left-twisted or right-twisted bobbin thread. Shown as

Fig. 10, holding the thread, twist it with right hand in

the direction of arrow, if it becomes tight, it is

left-twisted thread. Otherwise, it is right-twisted

thread. .

Please use the model DDX1 24# 27# needle.

The needle must be suitable for the materials. Sewing

too heavy-duty materials and using too thin needle,

the needle would be broken, thread skipping and

breaking. If the needle too heavy, it would damage

the fabric. So please choose the suitable needle

according to the materials. .

Note: Fig (b): no fully insertion

Fig (c): wrong direction of long groove in

insertion

Note: Fig (b): no fully insertion

Fig (c): wrong direction of long groove in

insertion

10. Trail run

11. Installing the needle (Fig. 7)

12. Coordination among the needle, the

thread and the material (Fig. 8)

Long groove leftward

Clearance

a

b

c

Loading...

Loading...