A

B

C

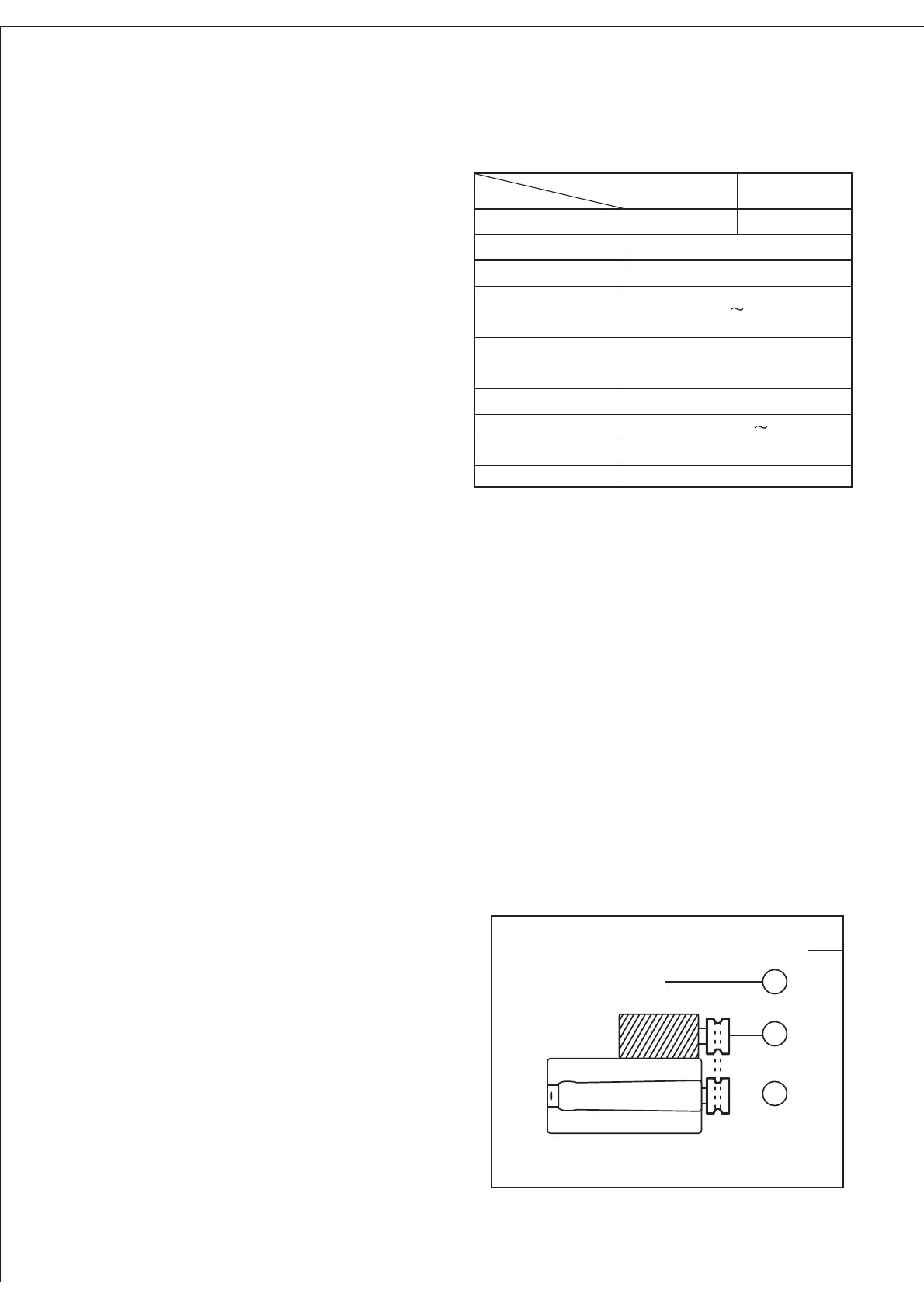

Max. Sewing speed

Max. Stitch length

Presser foot lifting

Alternate press foot

lifting range

Timing of walking foot

and feed dog

Rotating hook

Needle

Lubrication

Clutch motor

Max. Sewing speed

Max.

Stitch length

Presser

foot lifting

Alternate

press foot

lifting

range

Timing

of walking foot

and

feed dog

Rotating

hook

Needle

Lubrication

Clutch

motor

-1-

1

Model TW1-2B/2BL20 extra heavy duty top and

bottom feed lockstitch sewing machine with large

hook adopts single straight needle, link thread

take-up, high precise bevel gears driving, large hook

catching thread. With special upper feed mechanism,

the machine shows its good performance on sewing

extra heavy duty and extra thick thread.

It is widely used on sewing suitcas s, leather, sofa,

tents, bamboo matting, ect.

.

.

e

Model TW1-2B/2BL20 extra heavy duty top and

bottom feed lockstitch sewing machine with large

hook adopts single straight needle, link thread

take-up, high precise bevel gears driving, large hook

catching thread. With special upper feed mechanism,

the machine shows its good performance on sewing

extra heavy duty and extra thick thread.

It is widely used on sewing suitcas s, leather, sofa,

tents, bamboo matting, ect.

(1) Cleaning the machine

Before delivery, the machine parts are coated with

rust preventive grease, which maybe hardened and

contaminated by dust during storage and shipment.

The grease and dust must be removed by clean cloth

with gasoline.

(2) Examination

Though every machine is confirmed by strict

inspection and test before delivery, the machine parts

maybe loosed or deformed after a long distance

transportation with jolt. A thorough examination

must be performed after cleaning the machine. Turn

the balance wheel to see if there is running

obstruction, parts collision, uneven resistance or

abnormal noise. If there exist adjustment must be

made accordingly before running.

.

.

.

.

(1) Cleaning the machine

Before delivery, the machine parts are coated with

rust preventive grease, which maybe hardened and

contaminated by dust during storage and shipment.

The grease and dust must be removed by clean cloth

with gasoline.

(2) Examination

Though every machine is confirmed by strict

inspection

and test before delivery, the machine parts

maybe loosed or deformed after a long distance

transportation with jolt. A thorough examination

must be performed after cleaning the machine. Turn

the balance wheel to see if there is running

obstruction, parts collision, uneven resistance or

abnormal noise. If there exist adjustment must be

made accordingly before running.

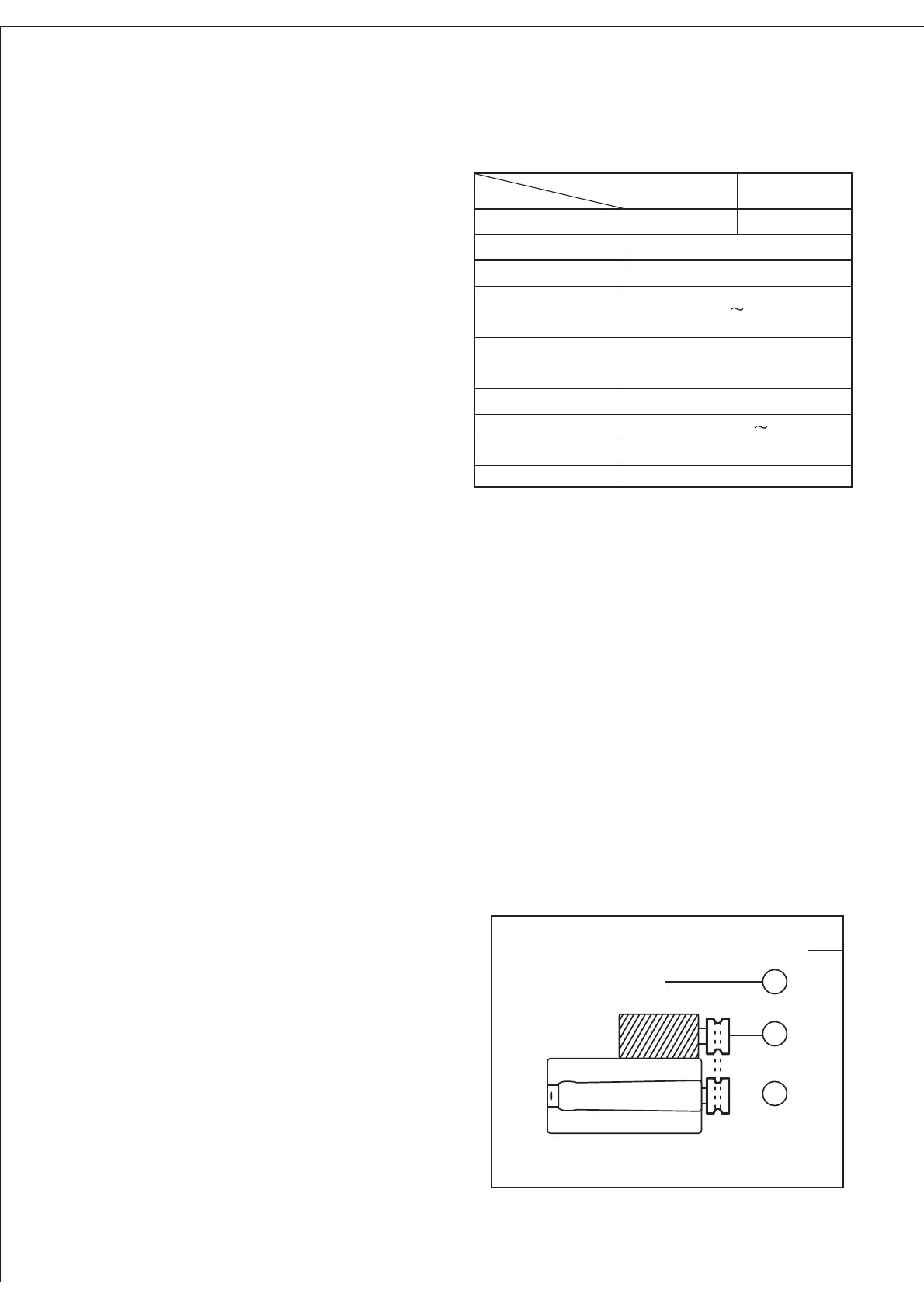

Align machine balance wheel belt groove (A) with

motor pulley belt groove (B) by moving motor

leftward or rightward. .

Align machine balance wheel belt groove (A) with

motor pulley belt groove (B) by moving motor

leftward

or rightward.

1. Brief introduction

3. Operation and preparation

4. Installing the clutch motor (Fig. 1)

2. Main technical specification

1200s.p.m

13mm

13mm by hand, over 13mm by knee13mm by hand, over 13mm by knee

4mm 6mm4mm 6mm

Max stroke is more than 13mmMax stroke is more than 13mm

Extra large hookExtra large hook

DDX1 24 27

##

DDX1 24 27

##

Lubricated by handLubricated by hand

0.5KW

TW1-2B

TW1-2BL20

Model

Parameter

900s.p.m

Loading...

Loading...