-8-

18

19

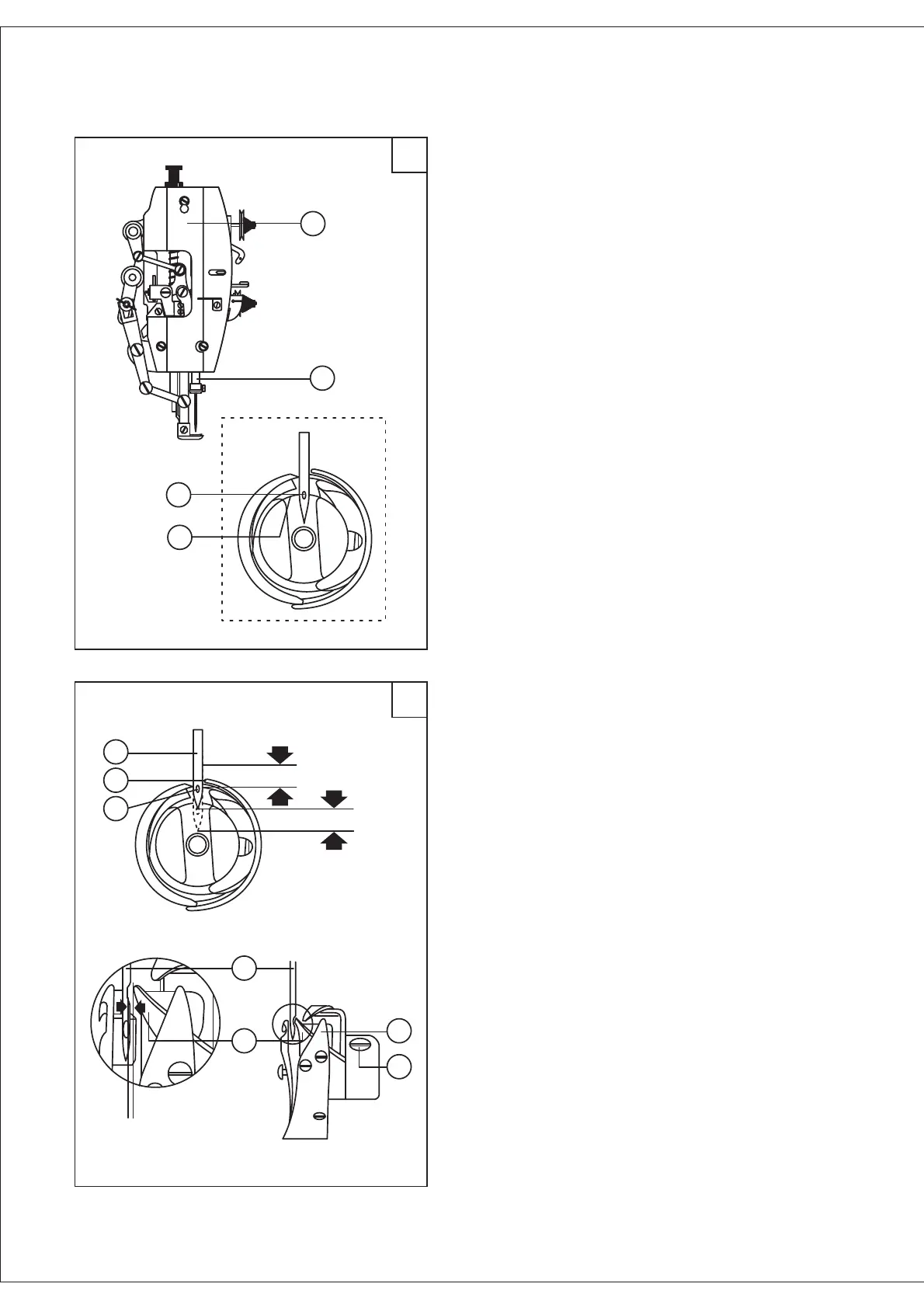

(1) Adjusting the position of needle bar.

Turn the balance wheel to make the needle bar (B)

to its lowest position. Remove the face plate (A), and

move the needle bar (B) vertically to locate the timing

position (the timing position of the needle bar is:

when the needle bar at its lowest position, the center

of needle eye (C) coincide with the inside surface (D)

of rotating hook). Tighten the screw.

.

.

.

.

.

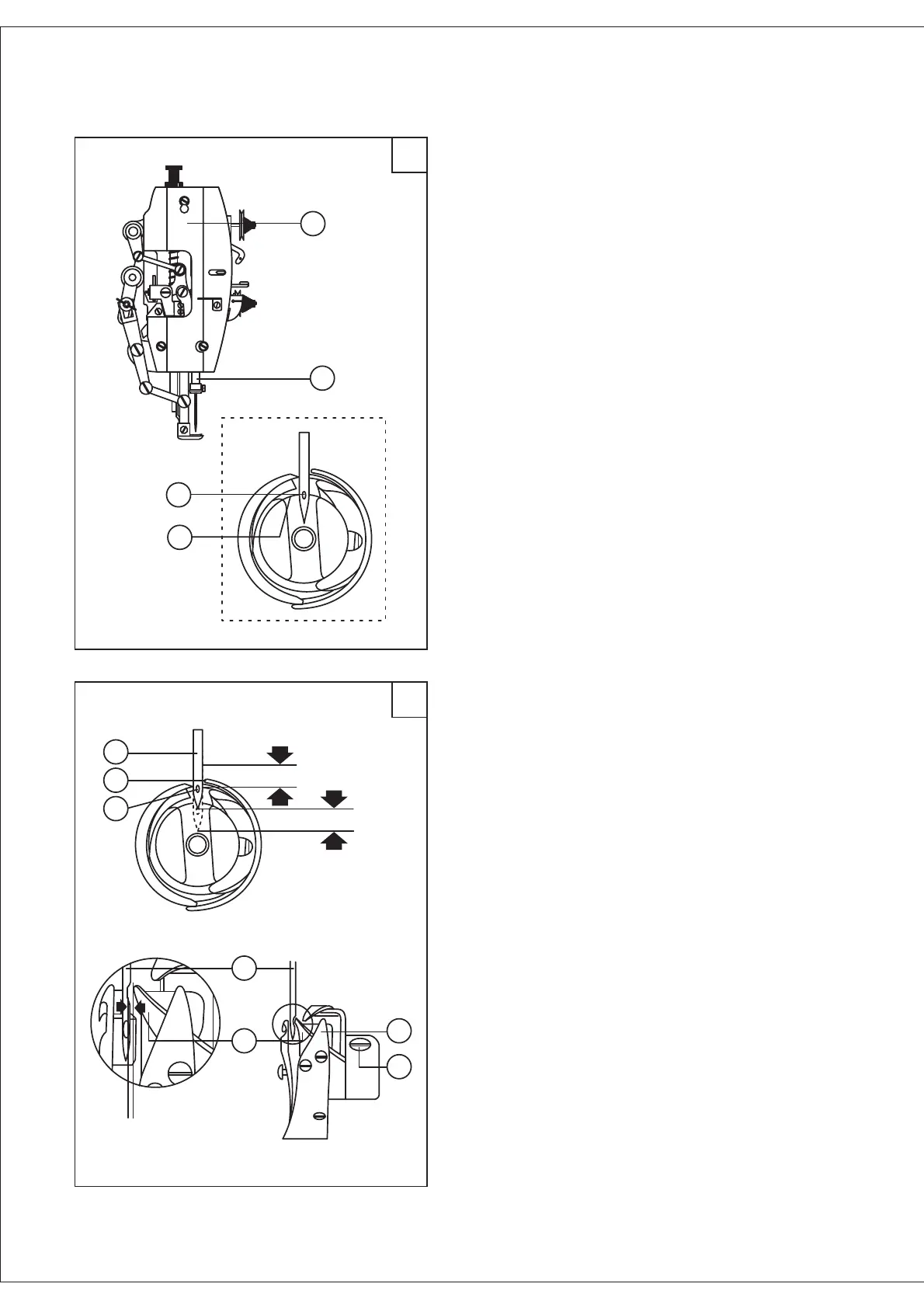

(2) Adjusting timing between rotating hook and

needle.

The motive relation between rotating hook and

needle affects the sewing quality. Standard timing

relation is: Turn the balance wheel to locate the

needle bar to its lowest position and lift back 3.8mm

height. The rotating hook head point (D) should be

coincides with the needle centerline (C). At this time,

the hook head point (D) is 2 2.5mm higher than the

needle eye (E).

When adjusting the timing relation, also please

notice the clearance between the hook head point and

side of needle. The clearance should be 0 0.1mm.

(1) Adjusting the position of needle bar. .

Turn the balance wheel to make the needle bar (B)

to its lowest position. Remove the face plate (A), and

move the needle bar (B) vertically to locate the timing

position (the timing position of the needle bar is:

when the needle bar at its lowest position, the center

of needle eye (C) coincide with the inside surface (D)

of rotating hook). Tighten the screw. .

(2) Adjusting timing between rotating hook and

needle. .

The motive relation between rotating hook and

needle affects the sewing quality. Standard timing

relation is: Turn the balance wheel to locate the

needle bar to its lowest position and lift back 3.8mm

height. The rotating hook head point (D) should be

coincides with the needle centerline (C). At this time,

the hook head point (D) is 2 2.5mm higher than the

needle eye (E). .

When adjusting the timing relation, also please

notice the clearance between the hook head point and

side of needle. The clearance should be 0 0.1mm. .

21. Timing between the needle and the

rotating hook (Fig. 18,19)

C

D

E

2~2.5mm

3.8mm

0~0.10mm

D

C

A

B

A

B

C

D

Loading...

Loading...