20

Establishing iColor Coating Unit Settings

The iColor coater is equipped with our “Patented” Coating Unit. This unique metering control

design provides a quick & EZ adjustment of the coating thickness, on the fly. Applying an even and

precise thin layer of coating, the Coating Unit produces the highest gloss and a perfect finish every

time.

The iColor Coating Unit has Six (6) main settings with additional positions between each settings for

precise coating control:

• (< 0) Position - END OF DAY POSITION (Do Not Coat in this Position)

• (0) Position - This is the calibration setting position (Do Not Coat in this Position)

• (1) Position - Lowest pressure (Heaviest Film of Coating)

• (2) Position - Medium Low pressure (Normal to Heavy Film of Coating)

• (3) Position - Medium pressure (Normal Film of Coating)

• (4) Position - Highest pressure - DO NOT EXCEED (Thin Film of Coating)

REMARKS: The recommended Coating Unit pressure setting is between (2) and (3).

CAUTION: When shutting the system down for the day, it is VERY IMPORTANT that you set

the coating unit metering controls to the “END OF DAY POSITION.” Failure to set the roller

pressure to the “END OF DAY POSITION” may result in a form roller at spot which is NOT

covered by our warranty!

NOTE: The Coating Unit form roller and metering roller are calibrated (set parallel) at the factory

and are set in the (0) position. Should the rollers need to be calibrated, please follow the Roller

Calibration Procedure on the next page.

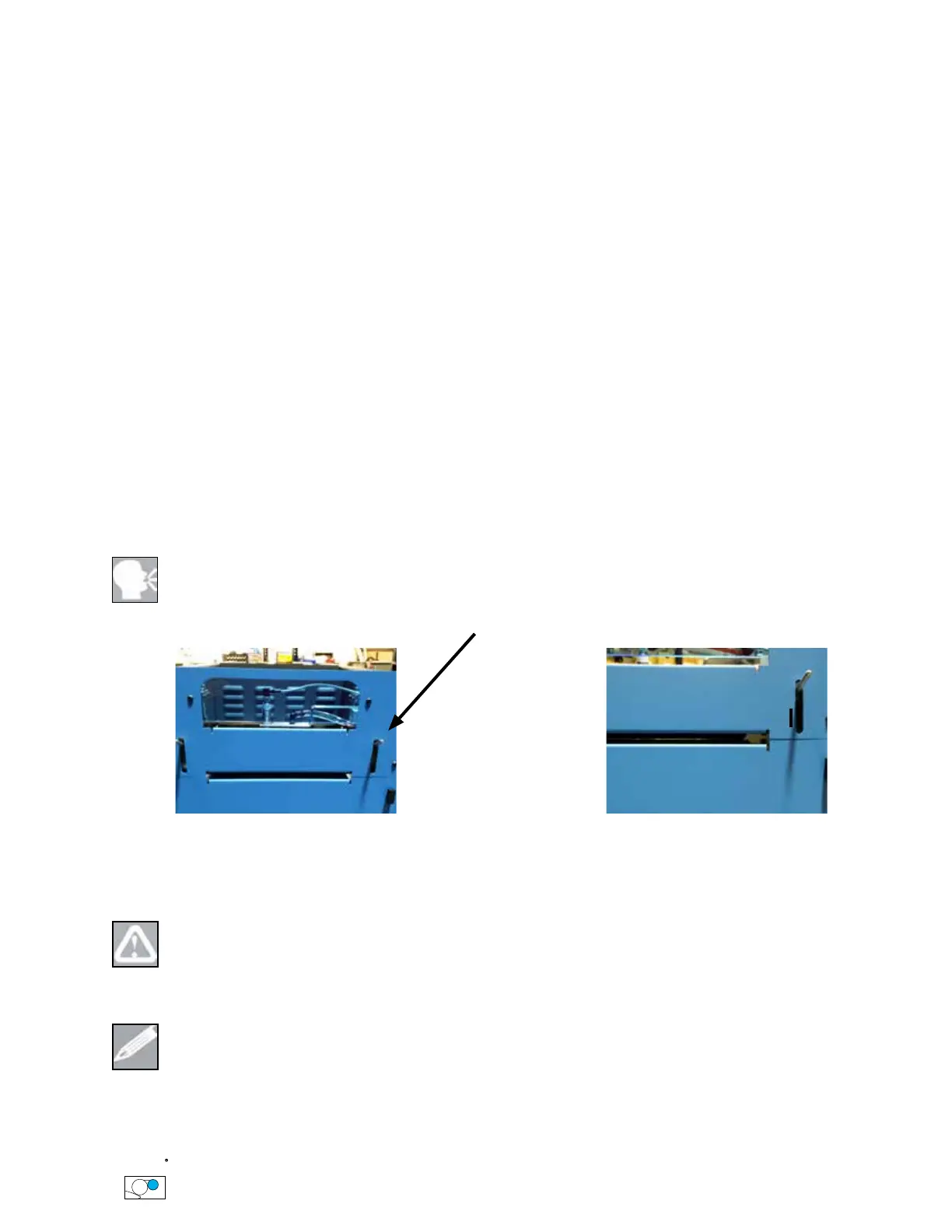

Figure - Coating Unit End Of

Day Position All the Way Up

Figure - Coating Unit Settings

Coating Unit Metering Gauge Adjustment

Loading...

Loading...